- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plaster

Results for

Plaster - Import export

KAYADERELI CONSTRUCTION

Turkey

It is a mold plaster used in shaping ceramics and ceramics.

Request for a quote

KAYADERELI CONSTRUCTION

Turkey

Repair and renovation application makes it practical. High addressability has.

Request for a quote

KAYADERELI CONSTRUCTION

Turkey

Repair and renovation application makes it practical. High addressability has.

Request for a quote

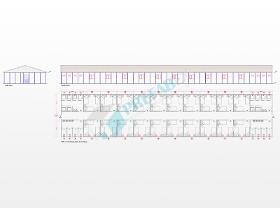

KALSEDON STONE

Turkey

SIMPLE APPLICATION, KALSEDON STONE PANEL PREFERED TO MAKE YOUR SPACES BEAUTIFULL WITH SPECIAL DESIGN

Request for a quote

OCTAMED SAGLIK URUNLERI SAN. VE TIC. A.S.

Turkey

Constructed from non-stretch transparent polyethylene film. Ideal for wound sites require frequent visual checks. It allows flexibility and comfort around the wound for easier movement and adjusts diagonally and horizontally for swelling. Used for many different applications such as fastening tubing and devices such as catheters and IV tubing, stabilization of finger splints. Specifications / Key Features: Easy, straight, bidirectional tear for customize sizing Porous for breathability Easy to handle with gloves Good adhesive to skin and tubing for securement Water-resistant Hypoallergenic X-Ray Permeable Leaving minimal adhesive residue upon removal Non- Sterile

Request for a quote

OCTAMED SAGLIK URUNLERI SAN. VE TIC. A.S.

Turkey

OCTAMED has 6 types of surgical tapes in different sizes with pharmacy and hospital packages. COTTON SURGICAL TAPE SILK-LIKE SURGICAL TAPE MICROPOROUS (PAPER) SURGICAL TAPE TRANSPARENT PE SURGICAL TAPE TRANSPARENT PU SURGICAL TAPE ELASTIC NON-WOVEN SURGICAL TAPE

Request for a quote

EPSA : INSULATION AND CONTRUCTION CHEMICALS

Turkey

a paintable, highly adherent and breathing mineral coating plaster,cement-based,developed specific to interior and exterior ,it covers application mistakesand provides a decorative outlook. color :white

Request for a quote

EPSA : INSULATION AND CONTRUCTION CHEMICALS

Turkey

A cement-based plastering mortar in appropriate particle size, which has high adhesive strength , is easy to process , specially designed for exteriors and can be applied both manually and by machine to bricks , primed exposed concrete,pumice concrete,briquette walls and ceilings.

Request for a quote

ONPO MADENCILIK

Turkey

Makonat is applied on bricks , concretes, gas concretes, pumice blocks etc. It is a bagged gypsum-based ready to use plaster that can be applied directly on materials with a machine. It is an A1 class fireproof material that provides sound insulation.

Request for a quote

ENTEGRE HARC INC.

Turkey

ENTEGRE Moulding Plaster - Plaster of Paris APPLICATION FIELD It is used in casting of requested models for decorative purposed and mounting of decorative gypsum plaster product to wall. It is also used in repair, restoration and renewal in housing and business places thanks to early freezing quality.

Request for a quote

ENTEGRE HARC INC.

Turkey

ALCIMATIK PLUS Gypsum Based Plaster for Application with Machine APPLICATION FIELD Applied on brick, Concrete, Autoclaved aerated concrete, Fair faced concrete, Bims, briquette, walls and ceilings in the interior faces of buildings.

Request for a quote

BELENEVIM

Turkey

- Cement-based, high performance, elastic thin plaster mortar containing special chemical additives, which is preferred in places where the ambient temperature changes suddenly or where it is flexible. SCOPE OF APPLICATION - On rough plaster indoors and outdoors in buildings - Plastering of thermal insulation boards in jacketing thermal insulation systems

Request for a quote

KAYADERELI CONSTRUCTION

Turkey

Its Standard :TS EN 13279 Water / Plaster Ratio: 10 kg gypsum in 5 - 6 liters of water Consumption Amount: 9.0 - 9.3 kg/m2 (every 1 cm thick) Brick, concrete, aerated concrete, grossconcrete, pumice block etc. of the material applied by machine. It creates a smooth surface in one coat. It saves time. It doesn't crack. It provides high strength. It is economical.

Request for a quote

SAREMICA

Turkey

2500*1200 12,5MM STANDART WHITE PLASTER BOARD

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 60 tons welded type cement silo is a big storage container integrated to execute the specialty of maintaining and producing a large amount of bulk cement. Mainly, these are integrated at construction sites and concrete manufacturing plants to ensure the appropriate and continuous supply of cement in various types of building projects. Mostly made up of steel, welded, and cylindrically shaped with a bottom cone, the cement silos are strong and well-built to bear the weight and pressure exerted by the stored cement. These 60-ton welded-type cement silos are best used for cement storage in huge quantities, and at the same time, the controlled gauge pre-fabrication of cement is needed when producing concrete. This makes it possible to store huge amounts of cement—60 tons—which in turn lowers the frequency of refills and optimizes the logistics cost of cement transportation. Silos are welded on the structural integrity and to minimize insemination and contamination chances.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 100 tons Welded Type Cement Silo is a large vessel designed for storing cement in bulk. This silo type is fabricated from welded steel sheets that provide strength and durability to the vessel, allowing it to bear the weight of the stored material and act against the external environment. Its substantial storage capacity, reaching 100 tons, enables it to handle and distribute cement effectively in many industrial and construction environments. Operational, a 100 tons Welded Type Cement Silo receives cement through pneumatic conveying systems or another loading mechanism into the silo. The cement then settles down at the bottom of the silo, consuming the available storage. In applications that require cement for production or construction, the silo's discharge system, usually screw conveyors or airslide mechanisms, provides controlled withdrawal from the bottom. This will ensure a constant supply of cement while keeping famous issues like clogging or material bridging to a minimum.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 50-ton welded type cement silo could potentially be a very large structure for concrete, cement. Those are usually applied and used at construct lines, concrete batch plants, and other industrial projects to store in addition to dispensing such objects. All-welded constancy in design guarantees their permanence and stability in long-term use with different ambient environments. The 50-ton capacity of the silo means the ability to provide a quantity that is possible to be on site well ahead of time to have the requirements of the construction met without delay. Even though the design is welded, the strength it gives is considerable enough for resisting harsh weather and, most importantly, ensures the cements stored therein are maintained safe and ready for fitting at desired times. To sum up, a 50-ton Welded Type Cement Silo- a ready and perfect solution for the storage of cement in required quantities for an ongoing construction project.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 120-ton Welded Type Cement Silo is a giant container in the shape of cylinder uprightness; it is used in holding cement basically in huge bulk quantities. These are developed out of very steel plates with the welded type, which gives the necessary robustness and strength with respect to the stored material weight on it. The welded design ensures that the silo is air and water-tight, preventing moisture and foreign materials from affecting the quality of the cement. Such silos are typically used in construction projects, where an uninterrupted and reliable supply of the material is to be maintained at all times. Large capacity of 120 tons eases bulk storage of huge quantities of cement at construction sites, eliminating multiple deliveries and hence sustaining an uninterrupted work process. Welded construction further eases their means of installation and maintenance; hence, the silos are best in their simplest and least costly form to meet cement storage needs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 60-ton Horizontal Type Cement Silo is a structure wherein a reasonably substantial amount of cement can be stored in a position that is horizontal with the help of the structure. It is very usual as silos in a majority of construction projects and concrete batching plants for efficient storage and transference of bulk cement. With the raised capacity of up to 60 tons, the cement storage of huge amounts is guaranteed as may be needed to meet the surging demand in various construction uses. Being horizontally structured, the 60-ton silo shares similar properties of easy mobility and installation and access in the construction sites to the top silos, and thus serves at enhancing the job site workflow and operational efficiency. The silos are usually fitted with a conveying system that allows the controlled discharge of cement according to the requirements of a construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 40-ton Horizontal Type Cement Storage Silo is indeed a specially designed storage container that is used to contain up to 40 tons of bulk cement in horizontal orientation. Such silos find major applications in construction projects, concrete batching plants, and industrial establishments where a huge amount of cement is needed in order to produce concrete. 40-ton storage capacity supports the adequate storage of cement, providing a reliable and stable supply of cement for the mixing of concrete. Due to the horizontal silo design, loading and offloading of cement are carried out in a horizontal manner, ensuring level ground at all times. This allows for easy access for maintenance, refills, and withdrawal. These types of silos are basically built in very strong materials, such as steel, to hold bulk cement properly and save it from external agents.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 30 tons Horizontal Type Cement Silo is a specially designed container able to contain as much as 30 tons of bulk cement in horizontal configuration. These are mainly used in construction projects, concrete batching plants, and other industrial works requiring large volumes of cement for the preparation of concrete. This horizontally designed silo enables cement loading and offloading at ground level to be simple, making it easily accessible for maintenance, refilling, and dispensing. Customarily made from robust materials like steel, these silos ensure the safe storage of cement and an environment in which its quality and integrity can be assured, while remaining readily accessible when needed for concrete mixing. The 30-ton capacity for a Horizontal Type Cement Silo only means the ability to hold large quantities of cement, most effective for mid- or big-sized civil construction projects that require a huge volume of the material.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 5000-ton bolted-type cement silo is a specially designed storage structure to contain 5000 tons of bulk cement or other powdered materials used in construction and industrial processes. These silos are necessities in concrete batching plants, construction sites, and industrial facilities where huge volumes of cement shall be stored safely and made readily available for use in production processes. Made of strong materials like steel, a cement silo of 5000 tons capacity has a strong cylindrical body and a support structure that needs to be resilient enough to be able to bear the weight of the material being stored. One bolted type cement silo of 5000 tons of massive storage capacity enables storing a large quantity of cement at one site, therefore feeding ongoing concrete production or construction or manufacturing operations, very much efficiently on a large scale. In the view of strength and great storage capacity

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 1000-tone Bolted Type Cement Silo is a specially designed storage specially designed storage container for holding bulk cement or other powdered materials, 1000 tons, normally used in construction and industrial applications. These silos form one of the main units of a concrete batching plant, construction site, and manufacturing facility where such large amounts of cement must be stored safely and made readily available for immediate production processing. Produced from strong materials, such as steel, the 1000-ton cement silo offers safe and efficient storage that ensures the quality and nature of the retained materials are preserved. A 1000-ton silo facilitates the storage of a large quantity of cement on-site so as to effectively support continuous production of concrete, construction works, or manufacturing. This large capacity allows the systems to cater for heavy production in big projects and large industrial set-ups.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 2500-ton bolted-type cement silo is a specifically designed warehouse unit for storage of up to 2500 tons of bulk cement or other powdered materials used for construction purposes and even industrial setups. These kinds of silos become of utmost importance because they store large volumes of cement safely, hence making sure there is a constant and reliable supply for use in all applications that cannot be calculated. Normally made with tough materials like steel, a 2500-ton cement silo would simply be a heavy cylinder, and underneath that shape, a whole structure is suspended to carry the weight of material stored inside. A silo of 2500 tons' capacity is therefore quite ideal for such large-scale undertakings that require constant iterations of quality concrete to keep the construction processes ongoing and for those industrial processes that demand substantial, relentless volumes of seemly concrete use.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 2000-tonne bolted-type cement silo is a highly dedicated storage unit designed for storing up to 2000 tonnes of bulk cement or other powder materials designed for building or industrial purposes. These silos form an integral part of concrete batching plants, construction sites, and industrial facilities where a huge quantity of cement needs to be stored safely and also has to be made readily available for production processes. Having been fabricated from steel, the 2000-ton cement silo will easily store the material inside without any contamination risks, thereby guaranteeing quality and integrity of the material. A 2000-ton silo has huge capacities that are instrumental in storing cement at the site, which then can constantly feed huge quantities into concrete production, construction, and manufacturing processes.

Request for a quoteResults for

Plaster - Import exportNumber of results

186 ProductsCountries

Company type

Category

- Concrete preparing - machinery and equipment (130)

- Bulk materials for construction (10)

- Plaster (6)

- Plaster and plaster products (5)

- Plasterboard (4)

- Plaster and plaster products - machinery and equipment (4)

- Metal furniture (4)

- Additives, cement and mortar (3)

- Laths, plaster-base (3)

- Building materials (2)

- Bandages and dressings (2)

- Cabins, cottages and chalets, prefabricated (2)

- Taps - adjustable controls (2)

- Medical Equipment (1)

- Construction Materials (1)

- Building bricks (1)

- Building materials, manufacture - machinery and equipment (1)

- Medicine - basic products and additives (1)

- Planting and sowing machinery and equipment (1)

- Boxes, cardboard (1)