- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection moulding machine

Results for

Injection moulding machine - Import export

NOVELTY STEEL

Turkey

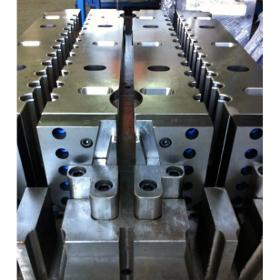

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Injection mold production is a complex process that cannot be underestimated. The resulting product is the main element to be used in injection molding machines. Therefore, at every stage of the process, there are improvements that need to be made in line with the research and the data obtained from these researches. The R&D process, which started with the examination of the samples we received, continues at the design and injection stages. As AYBERKSAN, our aim is not to present a large number of products with the existing data, but rather to increase the data we have and to present better quality, problem-free and economical solutions. The process we call development cannot happen without research. With this awareness, we, as AYBERKSAN Kalıp Sanayi, continue our research to take the experience we have gained so far to the next level, to add a new one and to develop it.

Request for a quote

MASSAN METAL

Turkey

Ekol stainless table legs, produced in injection molding machines, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their adjustable pingo system and unique appearance.

Request for a quote

MASSAN METAL

Turkey

430 quality stainless table legs, produced in injection molding machines, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their different colors, adjustable pingo system and unique appearance.

Request for a quote

MASSAN METAL

Turkey

304 quality stainless table legs, produced in injection molding machines, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their different colors, adjustable pingo system and unique appearance.

Request for a quote

MASSAN METAL

Turkey

304 quality stainless table legs, produced in injection molding machines, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their different colors, adjustable pingo system and unique appearance.

Request for a quote

MASSAN METAL

Turkey

304 quality Ekol stainless table legs, produced in injection molding machines, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their adjustable pingo system and unique appearance.

Request for a quote

MASSAN METAL

Turkey

Stainless Bistro table legs that are produced in molding injection machines and carefully painted with electrostatic powder coating system, are ideal products for your indoor/outdoor venues, hotels, restaurants, cafe/bars with their different colors, adjustable pingo system and unique appearance.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations Shoe Soles Injection Moulding Machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in three colours from materials such as TR, TPU, TPE and COMPACT/EXPANSE PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. The machine has full automatic, semi-automatic and manual system. In the cooling system which is accordingly designed, in the three parts water circulation channels are installed.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in two colours from materials such as TR, TPU, TPE and PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. The machine has full automatic, semi-automatic and manual system. In the cooling system which is accordingly designed, in the three parts water circulation channels are installed. The cooling plates are made of pressed aluminium and the cooling is provided as necessary.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional 1 Colour; 3 Working Stations Injection Moulding Machine for producing compact, extensive, strong, pliable or unpliable and very quality shoe soles from TR, TPU, TPE and PVC raw materials. The working of the machine is hydraulic and with closing of the presses. Thanks to the 3 direct active 120 tons cylinders connected to different heights of the various molds no mechanical adjustment is needed. 3 Stations 1 Colour Shoe Soles Injection Machine For each machine's administration, has been placed either hydraulic central or electrical central and the maintenance is done by the easily accessible centrals. Due to the technical characteristics the usage of other machines' molds is possible.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in two colours from materials such as TR, TPU, TPE and PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. For each machine's administration, has been placed either hydraulic central or electrical central and the maintenance is done by the easily accessible centrals. Due to the technical characteristics the usage of other machines' molds is possible.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient,practical and functional 2 working stations injection moulding machine for producing compact,extensive,strong,pliable or unpliable,quality shoe soles in 1, 2 or 3 colours from materials such as TR,TPU,TPE and PVC. The main characteristic of the machine is possessing the PLC control.In the machine are used Siemens products.The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable.Heating controls are connected to the PLC device.The machine has full automatic,semi-automatic and manual system.In the cooling system which is accordingly designed, in the three parts water circulation channels are installed. The cooling plates are made of pressed aluminium and the cooling is provided as necessary.Due to the technical characteristics the usage of other machines' molds is possible. With this machine at the cost of the ordinary one colour machine widely used you will get 1, 2 and 3 colours Shoe soles injetion moulding machine.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in single color from materials such as TR, TPU, TPE and Compact/Expand PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. Two Stations Single Color Shoe Soles Injection Machine.

Request for a quote

ROTAKEM

Turkey

Technicial Specifications: 1) Origin: Germany 2) Dimensions: 550x800x1850 mm 3) Press power: 175 tons 4) Weight: 375 gr 5) Motor power: 30 kW 6) Size of mold plates: 700x700 mm 7) Table size: 450x450 mm 8) Screw diameter: 80 mm 9) Screw stroke length: 1050 mm 10) Press type: Horizontal

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRUP HS MAKINE KALIP SAN. VE TIC. LTD. STI.

Turkey

The knowledge of design plastic injection mould is not enought, it is also important that the knowledge of operating plastic injection machine and polymer characteristics. Parameters used in injection machine are material injection temperature, injection pressure, speed, press time and push up feature. Designing injection mould with the knowledge of these characteristic provide both clients and us optimized mould manufacturing. Thanks to the plastic injection machine, founded in company structure, we are aware of following parameters. Our 30 years experienced staff can predict potential mistakes and we warrant trouble free and long duration mould manufacturing. We are assertive on low-cost and high piece injection capacity because of studying in design of modular calculation and flow diagram. Shrinkage of different materials are calculated with the 3D drawing programs by mechanical engineers of our company.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Injection moulding machine - Import exportNumber of results

17 ProductsCountries

Company type