- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial steam generators

Results for

Industrial steam generators - Import export

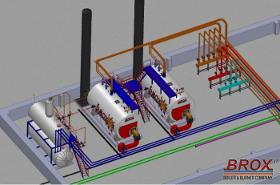

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

1 ton/h to 18 ton/h Industrial Fire tube Steam Boiler, generating superheated or saturated steam, fired Gas, Liquid and/or Solid fuels, turnkey project flexible solutions as per customer demand.

Request for a quote

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

18-20% fuel saving, efficient steam generator, generating steam in 3 to 5 mins. Due to it is modular design, number of generator in system can be specified as per customer steam demand and the generators starts and stops according to steam consumption.

Request for a quote

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

Fast Steam Generator, designed as Vertical or Horizontal, generating steam in 3 to 5 mins after cold start-up, Gas & Liquid fuels options.

Request for a quote

ENEVA ENERJI SISTEMLERI MUHENDISLIK SAN TIC LTD STI

Turkey

Indirect steam generators are used to produce saturated or superheated steam indirectly, using higher pressure steam, thermal oil or another heat carrier which already exist in the plant. By doing this way there will be no need for additional boiler room investment. (Fuel piping, chimney etc.) ISG type steam generators operates with primer fluid flowing inside tube bundles and seconder fluid (steam) produced outside of the bundle. Thanks to flanged design, tube bundle could be disassemled completely and easily for renewing or maintenance purposes. ENEVA can supply completely stainless steel indirect steam generators named “Clean Steam Generator“ or “Hygienic Steam Generator “ for medical sector or food processing plants.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam is a pressure vessel manufactured to store excess steam or waste vapors out of the operation of aquaria and to be used again when necessary. They are mainly used in gas concrete installations especially for the purpose of recovering the waste steam from the process. There are water and vapor phase zones in the steam chamber. The volume is 4/3 water phase. Steam The steam is stored in the battery in the hot water phase by injecting the steam into the water by means of the diffusers located below the water level and dissolving it in the water. When the steam is needed, the pressure of the hot water is lowered and the steam produced by the resulting phase change is transferred to the process to be used again. Using a steam bath; Up to 25% energy saving is achieved. They can both discharge steam and discharge at the same time. Suspended solid materials which are dragged together with the steam collapse under the liquid and the bluff is removed from the environment and the steam is

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam boilers with water pipes are boilers in which the water circulates and evaporates in the pipe. This high-capacity, high-capacity, high-capacity steam boiler. The combustion chamber is surrounded by a pipe-pipe-pipe joint. As a fuel in water pipe steam boilers; They use solid fuel, liquid fuel and gas fuel. n terms of safety, the water is more secure due to circulation in the pipes. Because of their lower water volumes, they are boilers that enter the regime more quickly.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Thanks to large contact surface of water with smoke pipes, high operational safety and longer boiler life are guaranteed. The small water volume provides a better inside circulation and safe heat transfer with faster steam generation time. Increased strength and flexibility with corrugated furnace that is manufacturing by Eralp in 900°C degrees. In 3-pass Shell boiler design, the heat load of furnace is less than 1,2 MW/m. The result of this design is an ideal combustion with less NOx emissions, thus it causes lower fuel consumption. Further gains in efficiency can be obtained by using economizer for feeding water by preheating and air-heater for combustion air heating. The energy of flue gas can be recovered and the efficiency of boiler system is increased 5-8%. According to pressure of boiler, efficency increase up to %91. Eralp manufactured the highest efficent boiler (totally efficiency=%98,4) with two economisers which efficency tested and approved by Notify Body.

Request for a quoteResults for

Industrial steam generators - Import exportNumber of results

8 ProductsCompany type