- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas heat exchangers

Results for

Gas heat exchangers - Import export

NC MANUFACTURING AND ENGINEERING

Turkey

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Exhaust gas bypass systems are made as additional equipment in exhaust gas heat exchangers. 3-way flap is required for bypass systems. By-passing the gas flow makes it possible to adjust temperature inside boiler (exhaust gas heat exchanger). Before delivery, we do a thorough test drive for every single damper, using actuator and special measurement equipment, to make sure that they function as expected and are ready to serve reliably on site. Availaible in steel, stainless steel or heat resistant materials Flange type and size depending on customer needs We develop dampers in different sizes and various temperature ranges Actuator options; Pneumatic actuator, Electrical actuator

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Heat transfer between a gaseous media and a liquid finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air, steam) and a liquid (for ex. water, seawater, oil) takes place in the air-/water heat exchangers. Very often air/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube radiators can also be used as air heater, air cooler or condenser To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. The great increase of the thermal efficiency when applying fin tubes allows a substantial reduction in size and costs of such cooling equipment. The surface of such tubes is substantially increased and consequently less tubes are required compared with exchangers with plain tubes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We design and manufacture products based on the project sent by our customers or according to customer requirements. Calculations, designs and projections according to customer demand and in accordance with ASME Code Section VIII Div 1 and 2 (American Society Mechanical Engineers), API 661, API 650 (American Petroleum Institute), TEMA (Tubular Exchanger Manufacturers Association), AD-MERKBLAATTER, CODAT, DIN, EN 13445, PED 2014/68 / AB and TSE. The most common processes in the Oil & Gas, Petrochemical & Chemical, Food & Beverages and Heavy & Light Industry require a significant number of equipment to exchange heat or to storage different fluids or components. The fluid can be either liquid or gas, and one of each flows into the tube and the other flow out of the tube is used to boil, condense or cooling the fluid.

Request for a quote

NOVELTY STEEL

Turkey

A heat exchanger is a device designed for the transfer of internal thermal energy between two or more fluids with different temperatures. Typically, these fluids are separated by a heat transfer surface to prevent mixing. Heat exchangers find applications across various industries, including process, power, petroleum, transportation, air-conditioning, refrigeration, cryogenic, heat recovery, alternate fuels, and more. Examples of heat exchangers encountered in daily life include automobile radiators, condensers, evaporators, air preheaters, and oil coolers. Heat exchangers can be classified in numerous ways based on their design and applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EVAPTON HEAT EXCHANGER

Turkey

IT IS THE MOST WIDELY USED HEAT EXCHANGER IN INDUSTRIAL FACILITIES SUCH AS IRON AND STEEL, PETROLEUM, PETROCHEMICAL, GAS, POWER PLANTS, FOOD, PHARMACEUTICALS, LEATHER, TEXTILES, AIR CONDITIONING, SHIPS AND MARITIME SECTORS THE HEAT EXCHANGERS USED IN THE INDUSTRIES CAN BE USED IN ALL SECTORS WHERE THERE IS A SECOND ALTERNATIVE ENERGY REQUIREMENT FROM AN ALTERNATIVE ENERGY WHILE ONE FLUID RUNS THROUGH THE TUBES, OTHER FLUID FLOWS OUTSIDE THE TUBES BUT INSIDE THE SHELL AS PARALLEL OR ACROSS THE TUBES. SO, HEAT IS TRANSFERRED OVER TUBE SURFACES. IT CAN BE PRODUCED AS COPPER TUBE, BAFON TUBE(CU-NI), STAINLESS STEEL AND STEEL.

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

EV SERIES SHELL&TUBE EVAPORATORS RANGE FROM 20KW TO 1510 KW COOLING CAPACITY IN EVAPTON'S STANDARD CONDITIONS. THE REFRIGERANT SIDE CAN BE MANUFACTURED FROM 1 CIRCUIT TO 4 CIRCUITS. EV SERIES EVAPORATORS CAN BE USED WITH HCFC AND HFC REFRIGERANTS WITH MEDIUM TO HIGH SYSTEM PRESSURE (30-45 BAR). EVA SERIES EVAPORATORS CAN BE MANUFACTURED BOTH IN STANDARD CATALOG SIZES AND IN THE SIZES REQUESTED BY THE CUSTOMER. EVERY EVAPORATOR MANUFACTURED IS CONTROLLED BY UNILAB LICENSE PROGRAM FOR CAPACITY AND PRESSURE DROPS AND TRANSMITTED TO THE CUSTOMER. EVS - SINGLE CIRCUIT EVAPORATOR EVD - DOUBLE CIRCUIT EVAPORATOR

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

EVAPTON WATER CONDENSERS ARE USED FOR CONDENSING THE REFRIGERANT GAS IN INDUSTRIAL AND COMFORT COOLING SYSTEMS AND ARE MANUFACTURED IN EVAPTON STANDARDS OR IN SPECIAL DESIGNS ACCORDING TO DEMAND. WHILE ECON-C SERIES CONDENSERS ARE PRODUCED FOR COOLING APPLICATIONS USING MAINS WATER OR WATER COOLING TOWER WATER, ECON-M MODEL CONDENSERS ARE PRODUCED FOR SEA WATER OR SALT WATER. IT CAN BE MANUFACTURED FROM 20 KW COOLING CAPACITY UP TO 1500KW COOLING CAPACITY.

Request for a quote

EUTECTIC PLATES

Turkey

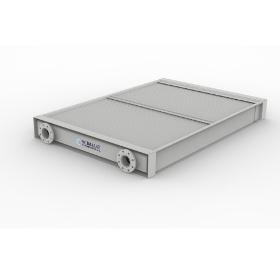

Rollbond exchanger evaporator for cooling or heating

Request for a quote

BLUE KLIMA

Turkey

Plate heat exchangers consist of a number of corrugated plates. The plate pack is mounted between a fixed and movable pressure plate, positioned by an upper and lower carrying bar, and compressed by several tightening bolts. The media involved in the heat exchange process are fed into the plate pack via connections on the fixed and movable pressure plates. The arrangement of the plates creates two separate channel systems, enabling the two media to flow past and between each other without physical contact, leaving the exchanger again via connections in the pressure plates. Plate with different patterns can be mixed in the heat exchanger in order to achieve optimum efficiency at a given pressure drop.

Request for a quote

RIMA HEATING SYSTEMS

Turkey

Heat exchanger from 24 kW to 3250 kW High corrosion resistant Excellent thermal conductivity High combustion performance with low exhaust emissions Easy operation and maintenance

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Energy Saving Products Heat exchange between fluids may sound ordinary and simple. But a properly designed stainless steel heat exchanger or condenser can both significantly reduce your costs and contribute to the environment friendliness of your processes. Flexible Design GEO heat exchangers, -especially the pipe type heat exchangers- which can be manufactured according to ASME and PEC design parameters, with reverse flow and multi-pass, are often preferred in processes such as cooling, air conditioning, heating, power generation, and recovery of alcohol and other organic chemicals in chemical reactions.

Request for a quoteResults for

Gas heat exchangers - Import exportNumber of results

14 ProductsCountries

Company type