- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixers

Results for

Mixers - Import export

PGR DRIVE TECHNOLOGIES

Turkey

PYK series products that have wide reduction ratio and high resistance against heavy and variable loads in horizontal, vertical and inclined feed mixing systems provide optimum solutions in TMR systems for cattle and small cattle livestock facilities.

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Suitable for Every Need Whether 500 liters or 50 tons, from the smallest capacities to the highest mixing speeds, mobile, fixed, vertical, horizontal, industrial, hygienic, stainless or carbon steel, GEO’s tailor-made, special design mixers are ideal for all kinds of mixing operations. GEO, with its expert staff and strong database, helps its customers to choose the most suitable mixer solution to use in their processes with detailed analysis. For renewal of existing mixer tanks or potential purchasings of new mixer tanks, do not order tanks without getting a quotation from us.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

300 LT LIQUID SPICE MIXER MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Our machine features a single-walled stainless steel boiler. Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 2 mm Liquid Spice Mixer - Mixer Gearbox: 80 RPM 0.75 KW Electrical components are SCHNIDER or DELTA brand. Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

POWDER SPICE MIXER MACHINE TECHNICAL SPECIFICATIONS The chassis is designed with consideration for strength and aesthetics. The chassis is entirely made of 304 CrNi material. Our machine has a single-walled stainless steel tank. The machine rotates around its axis to ensure a homogeneous mixture of powdered spices. Easy to clean both in dry and wet conditions. The tank plates are entirely made of 304 quality CrNi material. Tank Body Plate: 3 mm Tank Rear Dome: 3 mm It has a capacity of 600 liters. Maximum safety features. Easy to use with manual control panel. Machine Dimensions: Width: 120 cm Length: 220 cm Height: 220 cm GUARANTEE: The 600 LT Powder Mixing Mixer machine we manufacture; (Including production and fabrication errors) Chassis and tank manufacturing are under our 2-year warranty. Electrical switchgear components are under a 1-year warranty provided by the companies.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Meat Drum Meat Transfer Troughs lifting device is designed for food industry operations and is used for lifting and tilting manipulation carts. The trolley is designed to meet customers' requirements and the loading process of largely processed and unprocessed products. The part of a trolley filled with material is inserted into the tilting fork, which is a groove. Its advantage is that it is adjustable and can be produced according to customer needs. The fork provides easy and quick bending of the material into a machine where it is subsequently processed. It represents important additional equipment, the use and commissioning of which leads to acceleration and significant simplification of the entire production process.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

General description Our company has designed and manufactured the meat loading elevator machine by ensuring the following: – highest level of safety in operation, cleaning and maintenance; – the highest hygiene standards thanks to the correct material selection and the refined design of the elevator parts in contact with food in order to achieve easy cleaning and disassembly; – maximum efficiency with horizontal angle loading system; – hardness and stability of parts – lowest noise level - very useful Construction features The mixer consists of 304 stainless material and is resistant to rust and corrosion.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

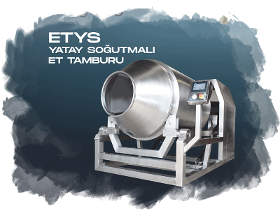

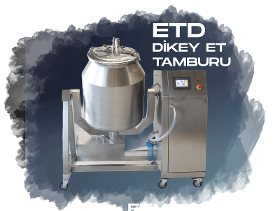

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 100 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to meat.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to meat.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS: Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: Front Dome: 4 mm Rear Dome: 4 mm Drum Capacity: 1000 liters Meat Carrying Capacity: 350 kg Vacuum System Hydraulic System Maximum Safety Automatic Ready Recipe Easy Operation with Digital Touch Screen Drum Bearing Rollers: FAG or SKF brand bearings are used. ETDYSH - 1000 Mixer Gearbox: 2.2 KW The reducers used are YILMAZ brand, KR series. ETDYSH - 1000 Meat Mixing Tulmbler: Equipped with one 0.70 KW vacuum pump. Electrical Components: Utilizing SCHNIDER or DELTA electrical components.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to the meat.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to meat.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to the meat.

Request for a quote

SAYGINLAR AGRICULTURE MACHINERY LTD.

Turkey

NAME OF THE PRODUCT: FEED MIXER WAGON MODEL OF THE PRODUCT: VERTI-12 TYPE OF AUGER: vertical DISCHARGE TYPE: optional VOLUME(cbm): 12 NUMBER OF AXLE: 2 NUMBER OF AUGERS: 2 HYDRAULIC POWER: Tractor NUMBER OF KNIVES: 16(8x2) OVERALL LENGTH: 5950mm MINIMUM REQUIRED HP : 70 HP OVERALL WIDTH: 2350mm POWER: PTO OVERALL HEIGHT: 2800mm optional BACK LOADER: WEIGHT: 4500kg SIDE OF DISCHARGE: right Sheet metal thickness of the auger 12 mm optional DIGITAL SCALE: PTO DRIVE 540 RPM Time spent to mix for one load 15minutes Sheet metal thickness of the bottom 20 mm Maximum number of Dairy Cows which can be fed with one load 90-100 cattle Sheet metal thickness of the side walls 6 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

We are producer of Planetary mixers from 10 L to 300 L. Main Specifications are floor model or bridge type model which are suitable for all kneading, mixing and whipping operations.Body painted with corrosion resistant electrostatical paint or AISI 304 stainless steel option. Powerful asynchronous motor with electronical speed variator. Water protected planetary system. Stainless steel bowl guard. Water proof button control panel with 60 minutes timer. Bowl position device allows the mixer to switch on only when the bowl and safety cover are properly positioned together.

Request for a quote

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

Dirmak Machinery ISM Series appeal many sectors to cater with a wide range of products from 10 litre up to 350 litre. Our machines provide to knead very short time thanks to excellent bowl and spiral apparatus design. Spiral mixer yields very quick preparation without warming and tiring products such as dough, mincemeat, cigkofte etc. ISM Series give power to your business with quite and smooth operation, durable and long-lasting.

Request for a quote

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

YB-1220 represents a new high-tech type of movable egg-laying concrete block machines, produced by Namtas since the beginning of 1980-s. This machine features high throughput and robust easy-to-use design. The machine moves on wheels along straight line on flat even concrete surface according to the specified program while moulding hollow, solid or insulated wall blocks from 185 to 300 mm in height directly on the floor. Delivery of fresh concrete from batching plant to the machine is done by a forklift equipped with a special hopper attachment. YB-1220 does not require production pallets and product handling systems to operate, minimizing customer’s initial financial input and reducing production costs. YB-1220 can be equipped with expanded polystyrene adding unit, allowing it to produce insulated wall blocks.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Namtas fully automatic batching plants are reliable and time-proven pieces of engineering being able to perform at their best in any conditions. They are designed specifically for the preparation of no-slump concrete mix (dry-mix concrete), which is required for the manufacturing of high-quality concrete products. Namtas batching plants can be installed together with Namtas concrete block machines or integrated into already functioning concrete block production plant.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-20 is the most compact automatic stationary concrete products machine Namtas manufactures. This reliable time-proven machine is made specifically for those investors and entrepreneurs, who want to start the production of the variety of concrete blocks with minimum financial input, while still being able to manufacture high-quality products, such as paving stones, curbstones, hollow and solid masonry blocks, filler blocks, rain gutters and hardscape elements from 60 to 200 mm in height. NS-20 is integrated in Type A concrete block production plants without automatic cuber. This means cured products should be transferred from production pallets to the transport pallets using manual labour.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-30 and NS-25 are single-layer medium-pallet concrete block machines designed to manufacture high-quality concrete products, such as pavers, curbstones, hollow and solid wall blocks (including lightweight and insulated type), rain gutters and hardscape elements from 60 to 300 mm in height. The main difference between the machines is the size of vibration table, which is slightly bigger in NS-30. This increase machine’s production capacity for pavers and curbstones, as well as allows to produce 1 meter long curbstones lengthwise in the standing position. RIGID DURABLE FRAME AND PNEUMATIC MOULD BOX CLAMPING Both machines has a robust heavy-duty frame welded of rectangular steel tubes 150 x 150 mm. Mould and compaction head carriers are mounted on 4 80mm chrome-plated guiding columns. Mould is attached to the mould carrier via 4 airbags while compaction head is attached to the compaction head carrier via bolts.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Being the best-selling model among all Namtas concrete products machines NS-36 combines durable and reliable design with high throughput and best price/performance ratio. These features contribute to the fast recouping of the capital invested in the machine. Equipped with fast mould changing device, NS-36 is capable of manufacturing a large variety of concrete products, such as paving stones, solid and hollow concrete blocks (including insulated type), filler blocks, curbstones, concrete gutters and hardscape units from 60 to 400 mm in height. HEAVY-DUTY SOLID FRAME Machine frame is a robust heavy-duty structure welded of rectangular steel tubes 150 x 200 mm. Reinforced hard-chromed guiding columns and supporting them linear bearings stabilize the mould and minimize its oscillation.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Combination of company’s experience and modern technology is embodied in a new high-performance large pallet concrete products machine of NT series – NT-42. This machine represents the crowning achievement of a long and laborious work of Namtas’s engineers in collaboration with The Scientific and Technological Research Council of Turkey. Following years of research and tests this machine was successfully launched into production in 2015. This multi-purpose machine is designed to manufacture a large variety of concrete products including pavers, hollow blocks, filler blocks, curbstones, rain gutters and hardscape elements from 60 to 500 mm in height.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Combination of company’s experience and modern technology is embodied in a new high-performance large pallet concrete products machine of NT series – NT-36. This machine represents the crowning achievement of a long and laborious work of Namtas’s engineers in collaboration with The Scientific and Technological Research Council of Turkey. Following years of research and tests this machine was successfully launched into production in 2015. This multi-purpose machine is designed to manufacture a large variety of concrete products including pavers, hollow blocks, filler blocks, curbstones, rain gutters and hardscape elements from 60 to 500 mm in height.

Results for

Mixers - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Mixers and grinders for the food processing industry (14)

- Concrete mixers (7)

- Brick-making - machinery and equipment (7)

- Concrete blocks (4)

- Bakery - machinery and equipment (2)

- Meat processing machines (2)

- Bakery and confectionery industry - machinery and equipment (2)

- Food industry - machinery and equipment (2)

- Mixers (1)

- Animal feeding equipment (1)

- Handling - Machines & Equipment (1)

- Livestock and poultry - feed (1)