- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screen

Results for

Screen - Import export

TEKNOFOAM AKUSTIK IZOLASYON SANAYI VE TICARET LIMITED SIRKETI

Turkey

Pet polyester acoustic felt screen divider panel is a sound insulation material used in offices, meeting rooms, restaurants and other commercial areas. This panel is designed to help block out high sound levels, providing a more comfortable environment for employees, customers and other users. Acoustic pet polyester felt screen partition panel is produced with the properties of pet polyester material. This material is derived from recycled plastic bottles and is an environmentally friendly option. It is also ideal for soundproofing because it absorbs loud sound waves and reduces echo. Acoustic screen has a more aesthetic appearance thanks to the felt coating on its surface and can be used as a decorative element.

Request for a quote

TEKNOFOAM AKUSTIK IZOLASYON SANAYI VE TICARET LIMITED SIRKETI

Turkey

Separator acoustic screen panel is a panel that provides sound insulation and is used to divide an area into more than one section. This panel is often used in offices or meeting rooms to provide sound insulation and privacy. The acoustic panel is usually made of high-density fibers, and the materials inside help absorb reflected sounds and prevent them from passing to the other side. Thus, it reduces the noise inside a room, ensuring that it does not interfere with the work or meetings of people in other rooms.

Request for a quote

AKSA ACOUSTIC SOUND INSULATION MATERIALS

Turkey

The Acoustic Screens is made of 40 mm thick high density glass wool plate covered with acoustic sound absorbing fabric on the front and back surface . 100 mm high feet provide good air circulation in the rooms. The highdensity glassfiberboards that are seated in aluminum profiles are covered with different colors of available fabric. Depending on the size of the area to be used, the desired panels are mounted to each other. Aluminum frames can be painted in any desired color.The acoustic dividers can be used in any acoustical environment to ensure that the areas are adequately partitioned in large areas where noise is intense. It is preferred for partitioning the tables in the office, such as office and call center.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

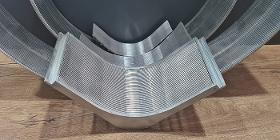

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

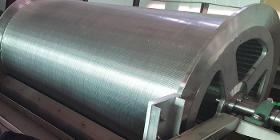

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Intake screen also called T-screen is used to intake and clear water in many industrial areas. They are commonly used in hydroelectric, agricultural, drinking applications to prevent dirty materials from the water. Intake screen is commonly used in lakes known as lake pump intake screen. Intake water works as passive intake screen to intake of water for generating electricity for hydropower. Water intake filter screens can intake clean water by eliminating unwanted materials. Because of its simple cleaning, major maintenance is not required for the operational time. Advantages: 1-High performance water filtration 2-Fish friendly 3-Corrosion resistance 4-Passive intaking water 5-High durability – less maintenance 6-Easy to install Applications: 1-Hydropower Intake 2-Lake Application 3-River Application 4-Water Cleaning

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages Special surface treatment Suitable & customizable design Long service life High durability – less maintenance Effective filtration The most popular usage of the panel filter screen is eliminating the big particles over the screen with vibration. Applications Food and Mineral Processing Water Cleaning Mining Applications Vibrational Separation Fermentation Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Coanda Intake Screen also called Coanda screen provides filtration with the special curve shaped wedge wire screen. Coanda Effect screen is mostly used for filtration of water depending on the Coanda effect principle. Thus, the shape of the Coanda screen helps the filtration process complete accurately by the exerted forces of flow. Advantages of Coanda Screen Water screen provides clean water to the channels with high performance and self-cleaning. The main advantages of the Coanda Effect screen are: 1-Special surface treatment 2-Customizable design for the application 3-No power requirement 4-Long service life with negligible operational cost 5-High intake performance 6-Effective cleaning and capacity The main applications of the Coanda Hydro screen are 1-Hydropower Plants 2-Agricultural Applications 3-Dewatering 4-Drinking Water 5-Sediment Filtering 6-Water Treatment 7-Waste Water Treatment We provide customized Coanda Screen depending on your project needs.

Request for a quote

STIL ELEKTRONIK

Turkey

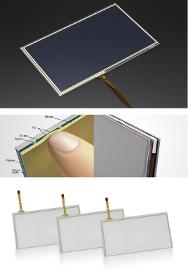

Crosswise Dimension (DS) / External Dimensions (E) / Screening Dimensions (V) / Active Dimensions (A)

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The most popular and effective way for the Coanda Screen, also called hydropower screen, is using it for the Hydroelectric Plants – Hydropower energy. Coanda Water Screen prevents harmful materials, sediment in the intake process, and provides clean water. Thus, turbine blades in hydropower plants can operate for longer without being damaged. Thus, the Coanda Intake Screen operates long years with negligible maintenance and with no moving parts. Main advantages of Coanda Effect Screen in hydropower plants: - Sustainable energy production and increased output efficiency - Self-cleaning and no power requirement - Increased income with continuous water intake - Durable protection bars and negligible maintenance - Specialised design for high water intaking performance - Protection of turbine blades from abrasion, sediment and debris We are able to improve your electric generation efficiency with our high capacity Coanda Sieb Screen.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Thus, centrifugal wedge wire screen is suitable for the different kinds of applications where accurate filtration is required. Advantages Special surface treatment Centrifugal customizable basket design Corrosion resistance Durable and long service life Precise filtration Strong mechanical properties Applications Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. Mining Applications Water Treatment Chemical Fertilization Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

TURKISH MANUFACTURERS UNION

Turkey

Our company, which was established in Trabzon in 2012 to provide import‑oriented motorcycle accessories service, started to serve as a motorcycle textile and accessory manufacturer for the first time in Turkey with the investment it made in Yalova in 2019. Our facility is the only factory in Turkey where all production processes and all quality processes are carried out in a single integrated facility. All products are designed and produced with care in the factory in Yalova, believing that the motorcycle is not a vehicle but a lifestyle. A product is produced every minute in our facility. It meets 95% of its raw material supply domestically. Our expert R&D team conducts research and works continuously for innovative products in order to meet the needs in the most accurate way. Known for our innovative design and dynamic marketing solutions, TIEN branded products are exported to many countries around the world

Request for a quote

POLIBAG AMBALAJ KIMYA SAN.TIC.ŞTI.

Turkey

stretch food food stretch

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

Pattern Coating

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

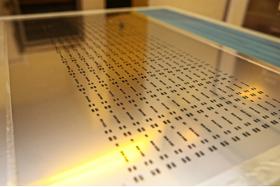

Our advanced systems ensure a continuous electronic exchange of information with customers over the INTERNET. Thanks to the GENESIS 2000 software, the technical information from the customers is converted into production patterns accurately and quickly, and the films are produced with printers to be used in the production stages.

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

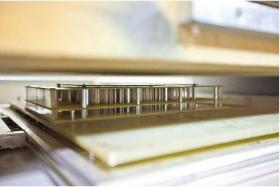

Laser cut stainless steel sieve, phosphorus-bronze, adhesive sieve Plate thicknesses: 80μ, 100μ, 120μ, 150μ, 200μ

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

Electric Test

Request for a quoteResults for

Screen - Import exportNumber of results

65 ProductsCountries

Company type

Category

- Screen filters (19)

- Screen printing on metal (10)

- Filtering equipment and supplies (10)

- Water treatment, industrial - systems and equipment (8)

- Display boards and screens, electronic (6)

- Screen printing on fabric (3)

- Mining and quarrying - machinery and equipment (3)

- Silk-screen printing (2)

- Screen printing on plastics and PVC (2)

- Screen printing - supplies (2)

- Inks (2)

- Sound insulation materials (2)

- Industrial screen printing (1)

- Crushing and grinding machinery (1)

- Filters, liquid (1)

- Flat screens (1)

- Room partitions (1)

- Heating - greenhouses (1)

- Medical Equipment (1)

- Medical imaging equipment and instruments (1)