- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling machines

Results for

Rolling machines - Import export

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

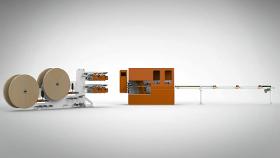

60m/min Core Rolling Machine is a machine that plays an important role in industrial production and is used to roll paper and similar materials. This machine has a technology that increases productivity and speed, especially in large-scale production. The 60m/min core maker Machine, which turns paper main bobbins into tubes at high speed and without interruption, significantly increases the speed and efficiency of the tube production process. 60M/min Core Machine is a machine used for making cores in the production of products such as toilet paper and kitchen towels in the paper converting industry. This machine, which is especially used in large-scale paper production facilities, turns the paper into cores and facilitates storage and transport processes. This machine attracts attention with its high speed and uninterrupted production capacity. High Speed and Efficiency: Designed for fast production processes, which increases production efficiency.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Complete turnkey roll forming machine line according to the finished final product with all necessary equipment, such as uncoiler, feeder, roll former, hydraulic or eccentric presses, stacking unit, etc. We offer standard models of roll forming machines as well as specific models according to the final product requirements of our customers. Some of our standard roll forming machine models are: • Warehouse racks and shelves • Market racks and shelves • Building and construction • C, U, Z, and Sigma (track and stud) • Guardrail • Roll-up door forming machine • Roof panel forming machine • Standing seam • Wall panel • Drywall and plasterboard • Snap lock • Cable tray • Scaffolding Just contact us for any roll forming machine you need, and we will find the optimal solution.

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

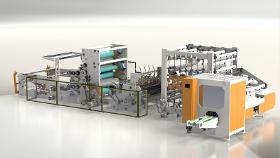

Automatic Dual Toilet Paper and Kitchen Towel Production Line is an advanced technology that offers a high-capacity and efficient production system that occupies an important place in the modern paper production sector. This production line stands out with its ability to produce both toilet paper and kitchen towels at the same time, thus increasing production flexibility and capacity. Equipped with advanced automation features, this line makes production processes faster and more efficient. Automatic (Dual) Toilet Paper and Kitchen Towel Production Line is an automatic production system that can produce toilet paper and kitchen towels at the same time. Thanks to its dual-functional structure, it can produce two different products on the same line and without interruption, which increases both the speed and efficiency of the production process. Dual embossing unit: Ability to produce both toilet paper and kitchen towels.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

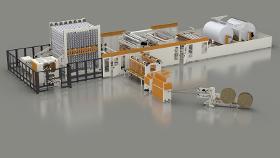

Non-Stop production Line is a technology that revolutionises the production of toilet paper and kitchen towels by offering a continuous and uninterrupted production process. This line significantly improves the efficiency of the production process and product quality with its high speed and continuous operation capability. With its non-stop production capability it enables an impressive production capacity to be achieved, especially in large-scale production facilities. Non-Stop Toilet Paper Line is an industrial line that can operate continuously and produce rolls (toilet paper, kitchen towel) without interruption in production. It maximises the efficiency of the production line and enables more production with less workforce. Continuous operation feature means time and cost savings in production processes. Continuous and Non-Stop Production: Continuous production capability at high speed.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed. Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities. Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups. Double Embossing Technique: Ability to wrap products with two different embossing patterns. High Efficiency: Fast and uninterrupted production capacity. Flexible Production Options: Ability to process paper of different sizes and thicknesses. User Friendly Design: Easy operation and adjustable features.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Combining aesthetics and functionality in toilet paper and kitchen roll production, the 5 Embossed Toilet Paper and Kitchen Roll Machine has a technology that gives extra softness and absorbency to paper products. The embossing process increases both, the visual and tactile quality of the product by adding embossed patterns to the paper surface. If high quality and standard are needed for toilet paper and kitchen rolls, this machine is ideal. The Toilet Paper and Kitchen Roll Machine with 5 Embossings is a production machine that adds special embossed patterns to paper products. This machine adds aesthetic and functional reliefs to the surface of toilet paper and kitchen rolls by using special embossing rollers. These embossings increase the paper’s softness and absorbency, thus improving the product quality. High Quality Embossing Process: it gives an aesthetic and tactile superiority to paper products.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

La machine de rembobinage automatique de papier toilette et d'essuie-tout est une machine axée sur l'efficacité et la qualité qui automatise le processus de rembobinage des produits en papier. Cette machine augmente la qualité et la facilité d'utilisation des produits finis en assurant un enroulement précis et régulier du papier toilette et des essuie-tout. Cette machine, qui occupe une place importante dans les installations de production modernes, attire l'attention par sa rapidité et sa capacité de production continue.

Request for a quote

KASSERIA KARUM

Turkey

Avaliable; Hand roll / Machine roll / Jumbo Width: 30-35-40-45-50 Thickness : 8-24 mic. Length : 50 m – 300 m

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

This is Yeniada Makina's printed roll slitting machine for big rolls into small rolls. It has automated tension control, 7" control panel, automated edge control , airshaft roll holder, meter counter.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

Yeniada Makina’s folding machine , used to fold printed rolls into new roll Machine features: Working speed up to 150 meters per minutes Meter Counter Automated tension control system Airshaft roll holder 7″ touch control panel Edge control system Custom roll width design

Request for a quote

ERDE MACHINE

Turkey

We produce and supply high quality spare parts and components for toilet paper roll converting machines at cost-effective prices. For further info, please contact us at website below. https://www.erdemachine.com/en/

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GALATAMAK ENDUSTRIYEL MAKINA SAN. TIC LTD. STI.

Turkey

Ability to manufacture much longer profiles fully symmetrically compared to the bending presses 20 m/min forming speed Profile width from 100 mm to 450 mm, manually adjustable Possibility of one-side forming Ability to produce different profiles by changing roll tools within minutes (if the profile section is applicable)

Request for a quoteResults for

Rolling machines - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Toilet paper (6)

- Rolling mills - machinery and installations (3)

- Rolling machines (1)

- Metallurgy - machinery and installations (1)

- Profiling shapers (1)

- Adjustment - machine tools (1)

- Cutting, plastics - machinery (1)

- Folders, paper (1)

- Folding machine tools (1)

- Metal engraving - machine tools (1)

- Metal industrial presses (1)

- Paper - manufacturing machinery (1)

- Paper - raw materials (1)

- Plastic packaging (1)