- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pvc%20profiles

Results for

Pvc%20profiles - Import export

MODULE-T

Turkey

Area of usage o prefabricated guardhouses and kiosks – Guard for control and security of construction sites and sensitive areas – Observation cabin related to the work on the construction site – Ticket booth – Kiosk for different pointsofsell Our stands and kiosk sandwich panels consist of rockwool, polyurethane or polystyrene insulation with a minimum thickness of 40 mm. Walls high galvanized and painted steel surface or aluminum surface sandwich panel walls. Guardhouse container with an inner and outer rockwool, polyurethane or polystyrene foam insulation sandwich panel walls. Door and window profiles aluminum or PVC with the following options large window, oriel window, sash window, aluminum or PVC shutters, shades, steel bar for doors and Windows to prevent unauthorized entering). Floor covering Construction site cabin and kiosk with pvc vinyl flooring (optional parquet, ceramic, steel or aluminum sheet). Possibility to add sanitary system

Request for a quote

TUNEL GROUP SOGUTMA SISTEMLERI

Turkey

They are the profiles used in the assembly of floor, wall and ceiling panels. Profiles can be PVC or polyester coated galvanized sheet or CrNi according to the panel surface. edge and corner joints, installation of hygienic and ceiling panels.

Request for a quote

AHP PLASTIK MAKINA

Turkey

PVC profiles’ breakage, cave in impact tests are performed by falling weight method. Matching fitting for samples in different diameters is available. Manually controlled easy to use feature. Max. falling height : 150 cm. Falling weight head radius : 25 mm, Falling weight : 1 Kg, Brake unit prevents the subsequent impacts and provides accurate measurement.

Request for a quote

SLIDING DOORS AND WINDOWS

Turkey

schuifdeur, schuifraam, upvc ramen. pvc deuren. aluminium rolbesturing. Met 17 jaar ervaring in deze branche bedient Fettahoglu Pvc de beste pvc-ramen en -deuren voor onze nationale en internationale klanten. Met CNC-machine en deskundige werknemers staan we klaar om u en uw klant van dienst te zijn.

Request for a quote

INO MACHINERY

Turkey

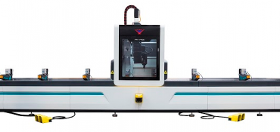

CNC profile machining center with economical design cabin moving on X-Y-Z axes. It can work on aluminum and PVC profiles. Specially designed for door and window profiles. It works on profiles with a high-speed spindle moving on a steel body equipped with a CNC controller unit and servo motors. The reference point at the beginning and end of the machine is lifted manually and determines the zero point of the profiles. Profile clamping pneumatic vices are placed on linear guides in 4 units as standard equipment. It works with Uni_Link, customized software for door&window manufacturing, and the clamp positions are displayed on Uni_Link’s own interface. Thanks to the Uni_Link program, Dxf drawings of door and window profiles are exported to the machine HMI. The size of the door profile to be processed is entered, hinge type, lock type is selected, and the machine performs parametric calculations on the profile perfectly.

Request for a quote

YILMAZ MACHINE

Turkey

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor Remote connection via internet and providing technical support

Request for a quote

YILMAZ MACHINE

Turkey

PIM 6508 is 8-axis CNC controlled machining center which is specifically designed to process any kind of PVC profiles in the market. The machine can do all operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6508 has the programming feature which provides minimum waste and maximum amount of production. 10 pieces of PVC profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. Operator attaches barcodes on the processed profiles to make them ready for welding operation. Servo control system providing CNC motion at 8-axis Fully automated feeding, carrying, positioning, cutting and transferring units Performing operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc.

Request for a quote

YILMAZ MACHINE

Turkey

Cnc controlled 4 corner pvc profile welding and cleaning line enabling movement in 2-4 axes Yılmaz makine custom profile cleaning programming Manual and automatic operating modes, Automatic profile recognition Automatic profile cleaning blade with 11 sets Separate cleaning blades for color and white profiles Profile width & height and frame wing control sensor Automatic bearing lubrication system Windows based touchscreen computer Profile program transfers via USB flash memory Remote connection and technical support capability Movable control panel, In process speed changes 220 frames/8 hours ( CNC 608)-270 frames/8 hours (CNC 608) On screen alarm and warning displays Phase control system, Low pressure control system Ability to clean all 4 corners and end-of-line transfer with automatic profile rotation robot Automatic system allowing for movement in Ø3 axis (X, Y1, Y2) Yılmaz makine custom 0,2-2 mm. welding interval automatic transfer Automatic operating mode

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Automatic screwing of the steel reinforcement bar in the PVC profiles that comes out of PIM 6508 and PCC 6505 Profile Processing and Cutting Centers. Machine is fully compatible with the PIM 608 or PCC 6505 Processing & Cutting Centers Machine measure the length of the profile automatically and determine the number of the screw Automatic centering of PVC profiles at the screwing section by servo motor controller Screwing conveyorconveys PVC profiles that comes out from the Processing & Cutting Centers 2 pcs. of servo controlled screwing heads perform the screwing operation as per the program that is made by the operator Separately positioned screw feeding units ensure non-stop screwing operations Seamless screwing by the screw feeders positioned independently of screwing heads Technical support and trouble shooting can be done by remote connection by via VNC All error messages and system status information can be observed on the screen by using the HMI prog

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is designed to operate quickly and precisely lock’s holes on aluminum and PVC profile, without releasing the workpiece. Copy router with 1 vertical and 2 horizontal spindle motors ( 3 x 1.1 Kw 12.000RPM) Designed to perform quickly and precisely lock’s holes on 3 sides of the aluminum profile without releasing the workpiece Pneumatic 2 x horizontal and 2x vertical clamps Horizontal and vertical pneumatic tracers with 3 diameters Ø 5, Ø 8, Ø 10 mm Horizontal & vertical templates with standard figures for Aluminum and PVC profiles Smooth movement, high precision and great sensitivity provided with gas spring and ergonomic handles 1 m of roller support table at the right (with ruller) and left side Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits with Ø5mm, Ø8mm and Ø 10mm • Additional collets with, Ø 8 and Ø10 • Special templates Videolar TECHNICAL SPECIFICATIONS 3x1.1 kw 1 P 230 V 50-60 Hz 6-8 Bar 8 lt./ min.

Request for a quote

YILMAZ MACHINE

Turkey

AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the six sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time. An additional magazine for the saw blade with 350 mm dia. ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

YILMAZ MACHINE

Turkey

Machine is ideal for welding process of PVC plastic profiles at four corners. Fully automatic four corner welding of PVC window profiles at an angle of 90° Welding of a complete window frame or sash in one cycle All profile related welding parameters are individually programmable User-friendly operating system compatible to all optimization programs Parameters are set easily by means of 8’’ LCD color touch screen Automatic line can be made by combining with Cooling Unit (SA 250),Corner Cleaning Machine (CNC 608-610) and Rotating Robot (SA 260) Automatically setting of standard (2 mm) or seamless (0.2 mm) welding options Long time of Teflon using period by means of the roller system Automatically discharging of the frames after welding operation Colored and white profiles selection modes Saving of time by means of practical mold change system Operator safety barrier Adjusting the heat between 0-300°C via electronic thermostat Minimum welding measurement : 400 x400 mm

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Cnc controlled 4 corner pvc profile welding and cleaning line enabling movement in 2-4 axes Yılmaz makine custom profile cleaning programming Manual and automatic operating modes, Automatic profile recognition Automatic profile cleaning blade with 11 sets Separate cleaning blades for color and white profiles Profile width & height and frame wing control sensor Automatic bearing lubrication system Windows based touchscreen computer Profile program transfers via USB flash memory Remote connection and technical support capability Movable control panel, In process speed changes 220 frames/8 hours ( CNC 608)-270 frames/8 hours (CNC 608) On screen alarm and warning displays Phase control system, Low pressure control system Ability to clean all 4 corners and end-of-line transfer with automatic profile rotation robot Automatic system allowing for movement in Ø3 axis (X, Y1, Y2) Yılmaz makine custom 0,2-2 mm. welding interval automatic transfer

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4420 is a 4-axis servo-controlled machining center that is designed to perform drilling, grooving, notching, taping, sawmilling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin-walled steel profiles. Efficient and economic processing on the three sides of the profiles is possible with this fully automatic machining center. General Features: • It is designed to make operations on three surfaces of the profiles such as a hole, slot, corner relieve, saw cutting, tapping, flow drilling, etc. • CNC automation system providing motion control at 4-axis • Linear type of magazine unit for 11 standard tools and Ø180 mm of the saw blade • Flow drilling and tapping feature by means of encoder spindle (optional) • Automatic clamp recognition and clamp positioning are available • CNC controlled spray tool lubrication system • Pneumatically working 4 pcs of clamps for gripping the workpiece

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4310 is 3-axis CNC controlled machining center which is designed for the working of all kinds of aluminum & PVC profiles, light alloys in general and temporary operations of thin-walled steel profiles with special cutters. By means of the additional aggregate tool, various profiles can be machined with 4-axis movement. The machine can be used in tandem mode, a work method that allows to machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run "while the machine is operating. The machine has automatic vise positioning feature (with CAMPROX software) and equipped with magazine unit holding 8 tool-units (second magazine unit optional) with the possibility of placing 2 aggregate tools and 1 milling saw to perform machining on the 5 sides of the pieces. Isolated cabinet reduces the noise of machine and provides safety of the operator. GENERAL FEATURES: • Designed for all kinds of drilling, grooving,...

Request for a quote

YILMAZ MACHINE

Turkey

VK 420 is designed for the precise V cutting and 90° end notching operations with minimal off cut size on aluminum and PVC profiles. Machine is constructed to minimize the off cut size Hydro-pneumatic V sawing head infinitely adjustable according to the profile Manual adjustable of back fence working in T slot mechanism Double hand safety operation External adjustment of hydro-pneumatic saw blade feeding 90 degree of notching operation (optional) STANDARD ACCESSORIES • 2 x T.C.T saw blades, Ø 420 mm • 2 x Horizontal pneumatic clamps • Service spanner • Air gun • Spray saw blade lubrication system

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine which works with motor–belt mechanism, ideal for the serial end milling operations on aluminum and PVC profiles precisely. High quality end milling operations by means of the adjustable motor speed thanks to the inverter and potentiometer. Practical change of cutter provides ease of operation Fixing the workpiece firmly and at square by means of the vertical clamps and adjustable horizontal supports Safety operations with safety guard Cutter storage location in front of the machine Robust machine stand and support arms in front of the machine to provide end milling of profiles up to 2.5 meters Practical cutter adjustment by means of the gap parts Max. end milling profile height (H): 210mm Max. end milling stroke (W) : 615 mm Max. saw blade diameter: Ø185 mm Max. tool height : 150 mm STANDARD ACCESSORIES • 12x pneumatic vertical clamps with adjustable pressure valve • 6 x adjustable horizontal supports • Air gun

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION This machine is ideal for the single corner welding of PVC profiles between 30°- 180°. Enable the welding of all angles between 30°-180°infinitely adjustable All parameters such as melting and welding time, welding pressure are set independently Automatically start and finish the welding cycle Adjusting the heat between 0-300°C by means of the electronic thermostat Smooth welding operations for long profiles by means of rotating support arms Maintenance friendly, for example cleaning of the heater plate and changing of the Teflon is very easy by means of quick change system Practical adjustment of standardl (2 mm) or seamless (0.2 mm) welding options manually Standard equipped with height adjustable profile support arms on both side Clamping the profiles separately via foot pedal Saving of time by means of practical mold change feature Portable machine stand OPTIONAL ACCESSORIES Machine according to the profile height of 165 mm

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Machine is ideal for welding process of PVC plastic profiles at two corners. Fully automatic two corner welding of PVC window profiles at an angle of 90° Possibility of precise welding and cleaning of profiles between 30°-180° on the left head All parameters such as melting and welding time, welding pressure are set on the control panel independently Continuous precision of welding quality by means of linear rails Welding two corners of window frames or sash profiles are carried out in one cycle User friendly with practical Teflon change feature by means of the roller system Saving of time by means of most practical mold change system in the market Capable of adjusting the clamp and weld ing pressure according to the profile type Adjusting the heat between 0-300°C via electronic thermostat Practical setting of standard (2 mm) or seamless (0.2 mm for free of flashes) welding options

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CA 603 Single Corner Cleaning Machines are used for striping of bottom and top surfaces and cleaning outer corners of 90° PVC cleaning profiles. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps Stops automatically after stripping and cleaning operation PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Pneumatic tool fixing and releasing system Stripping blade levels are adjustable according to laminated and un laminated profiles Processing capability of 2 different PVC profile 4 different cutter set can be mounted on a modul (CA 603) STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200Wx 2~3 400V AC 50-60 Hz. 3000 D/dak RPM

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION After welding clean up down and corner sides of 90º PVC Profiles after welding. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Stripping blade levels are adjustable according to laminated and un laminated profiles Pneumatic tool fixing and releasing system Single or multi cleaning operations can be processed Automatic start up feature when profile placed on the table Stops automatically after stripping and cleaning operation STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200 Wx3 400V AC 50~60 Hz 3000 D/dak RPM D: 215 d: 32 mm. 36 Lt/dak. 6~8 Bar 92x 101x 143 cm 249 kg. 198 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION TK 500 Single Corner PVC Welding Machine, This machine is ideal for the single corner welding of PVC profiles at 90° GENERAL FEATURES Enable the welding operation at 90° Adjustment of standard (2 mm) or seamless (0.2 mm) welding options manually Welding possibility for the profiles at 140 mm high All parameters such as melting and welding time, welding pressure are set independently Automatically start and finish the welding cycle Adjusting the heat between 200°- 265°C by means of the electronic thermostat Easy and smooth welding operations for long profiles by means of rotating support arms Standard equipped with height adjustable profile support arms on both side Clamping the profiles separately via foot pedal Machine stand TECHNICAL SPECIFICATIONS 1.5 Kw 50 Hz. 230 V AC P N PE 6-8 Bar 20 Lt / dak Lt / min h = 130mm max. a = 90o 42x52x87 cm 73 - 90 kg

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine is ideal for welding process of PVC plastic profiles at two corners. Fully automatic two corner welding of PVC window profiles at an angle of 90° The possibility of precise welding of profiles between 30°-180° on the left head All parameters such as melting and welding time, welding pressure are set on the control panel independently Continuous precision of welding quality by means of linear rails Welding two corners of window frames or sash profiles are carried out in one cycle User-friendly with practical Teflon change feature by means of the roller system Saving of time by means of most practical mold change system in the market Capable of adjusting the clamp and welding pressure according to the profile type Adjusting the heat between 0-300°C via electronic thermostat Practical setting of standard (2 mm) or seamless (0.2 mm for free of flashes) welding options The movable right unit moves manually and left welding unit is fixed at 90°

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Used for screwing of reinforcement steel on the PVC door and window profiles fast and precisely. Automatic screw feeding unit Operates with foot pedal for screwing free of defects Screwing force and point are adjustable for various kinds of profiles and their models Long life use and easy and fast changing of bits Automatic stop after finishing screwing Safety key to prevent misuse Special, adjustment key for the height of screw Fixes the material firmly by automatic clamps to prevent movement during screwing Adjustable resting distance for the supported type of profiles Torque adjustment as per the screw Screw feed speed approx. 1.7 sec./pc. TECHNICAL SPECIFICATIONS 16 lt./syc. 6-8 Bar 41x 73x 192 cm 132.5 kg. 100 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on PVC and aluminum profiles up to 3 mm of thickness. Opening locks, drilling handles, hinges, espagnolette holes etc. on PVC and aluminum profiles Cast aluminum structure Corrosion proof bearing shaft Robust machine stand constructed from steel sheet Electroplated copy template Two pcs of tracer pins Ø5 router bit included Clamping capacity : W max.:130, W min.:10, H max:130, H min.: 20 mm STANDARD ACCESSORIES • Ø5 mm of router bit • Air gun • 2x left and right profile stops • 2x pneumatic horizontal clamps • Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits • Special copy templates • MA 240 centering apparatus • MKN 150 roller conveyor TECHNICAL SPECIFICATIONS 750W 400V 50~60 Hz / 550W 230V 50 Hz x:270 y:110 z:130 mm 14000 D/dak. RPM W:64 L:80 H:149 cm. 110kg. 72 kg.

Request for a quote

YILMAZ MACHINE

Turkey

DC 550 SK is a full automatic sawing machine which is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminum materials by means of double head sawing units equipped with Ø 550 mm of saw blades. Two-hand safety operation Equipped with CNC control system for precise angular adjustment Tilting range inwards 45° and outwards 22.5° Hydro-pneumatic saw feed Cutting accuracy +/- 0.1 mm 2 x pneumatic profile supports Windows based industrial PC and 15’’ LCD touch screen color monitor Facility to transfer the cutting list at ‘mdb’+'xls' format via USB and network Remote connection via internet and providing technical support Barcode printer & image print Automatic slicing feature Profile height measuring system (DC 550 SKH) The angle setting of the heads is ensured with servo control system The position setting of the moving head is en sured with servo control system STANDARD ACCESSORIES Equipped with saw blades 2 X Ø 550 mm

Request for a quote

YILMAZ MACHINE

Turkey

PCC 6505 is a servo controlled machine which is specifically designed for the serial cutting of any kind of PVC and aluminum profiles in the market. The machine is able to cut PVC and aluminum profiles into required dimension. Operator places 10 pieces of profiles of maximum length of 6.5 m and minimum length of 0.7 m on the feeding conveyor of the machine, and presses on start button. Machine start the cutting operation of the profiles by the help of high performance robot arm and saw unit as per the requested angle between the angle of 30⁰-150° then collocates on the outlet conveyor. Operator attaches barcodes on the processed parts to make them ready for the assembly. 500 mm of down-cutting saw blade Servo control system ensuring motion control at 5 axis Pneumatic gripper for accurate positioning of the profile Horizontal and vertical clamping of workpiece during the sawing operation Fully automated feeding, carrying, positioning, cutting and transferring units

Request for a quote

YILMAZ MACHINE

Turkey

DC 421 PBS is a full automatic sawing machine which is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminum materials by means of double head sawing units equipped with Ø 420 mm of saw blades . Two-hand safety operation Tilting automatically to 90° and 45° in wards for both angles. Manual adjustment of intermediate angles from 90° to 45° inwards Tilting automatically 90° and 45° inwards both angles Automatic slicing feature at 90° Hydro-pneumatic saw blade feed Cutting accuracy +/- 0.2 mm Solid steel construction of the body Automatically closing safety guards Windows based industrial PC and 15’’ LCD touch screen color monitor Facility to transfer the cutting list in ‘mdb’+'xls' format via USB and network Automatic changeover mode from cut to cut without any operator input Technical support via remote connection capability Barcode printer & image print

Request for a quoteResults for

Pvc%20profiles - Import exportNumber of results

41 ProductsCountries

Company type

Category

- Machines for the manufacture of PVC and Aluminium Doors and Windows (12)

- PVC windows (1)

- Greenhouses and glazing units (1)

- Autogenous welding machines (1)

- Construction - portable power tools (1)

- Cooling and lubrication pumps (1)

- Cutting - machine tools (1)

- Extrusion - steel and metals (1)

- Power saws, portable (1)

- Sawing machine tools (1)

- Sawmills - machinery and equipment (1)

- Testing equipment (1)

- Welding robots (1)