- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses

Results for

Presses - Import export

FHM METAL ISLEME

Turkey

We can produce molds in our press machine, taking into account the number of production, and we can prepare the order you want in the dimensions. With our gas metal and teak welds, we can produce quality welds for you.

Request for a quote

FROHLICH

Turkey

H_Frame Eccentric Presses Between 300-1000 tons.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

CEGA METAL MAKINA SAN. TIC. LTD. STI

Turkey

Pressed Metal Parts - please contact us for more information!

Request for a quote

BOSPORAS

Turkey

Our Servo Feeder model allows customers to save energy, space and reduces maintenance costs. AS models don’t need external guidance because they minimize the distance between Press body and the template.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Manual hydraulic cutting punch, 10 Ton force capacity , cutter based on customer request

Request for a quote

AHP PLASTIK MAKINA

Turkey

Hot press for making sheet from plastic granules, 7inch touch panel, pressure monitoring, water cooled heating plates

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

Turquoise es is designed for today’s generation of highspeed web and commercial presses. Turquoise es is a high-tech, high performance fountain solution andalso FOGRA and OEM approved. it gives clean and quick start up with reduced ink consumption.Thisallows to printers to work with ıesswater,lessink consump tion,quick dry andlesswaste. Because ofTeknova has sofisticated technology we also offers to printers more healthy and safe p roduct s with a very effective preservative ing rid ents which prevents bacteria growth in pipesand dampening system.Turquoisees has antifoaming agent and fully biodegradable system in its formulation PROPERTIES Easy and qu ick start up. No need to change the press adjustments. Minimum ink emulsification,soink can stayconsistent during press run . Very qu ick adoptat ion withdifferent ink and paper quality Givescalcium control at all levelsof water hardness. Eli mina tes calcium deposit

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Our press shop has eccentric and hydraulic presses with a capacity range from 30 tons to 500 tons and all sheet metals such as INOX, Aluminum and DKP from 0.5mm to 8mm can be processed in our facilities.

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

Due to the fact that punching and cutting processes are performed with molds in single-sided printed circuit board production, our company has established its own mold production facility. Printed circuit information from customers is converted into a format suitable for mold production machines in the CAD/CAM work preparation center and transmitted to the mold center via the local computer network. In this center, necessary mold drawings are made using this information, and molds are produced quickly and precisely on state-of-the-art machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

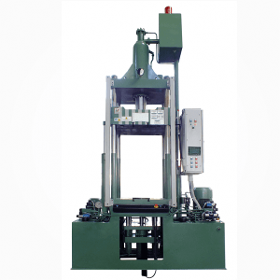

OZKOC HYDRAULIC MACHINE CO.

Turkey

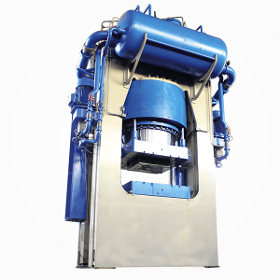

urea, melamine, smc hot hydraulic press

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

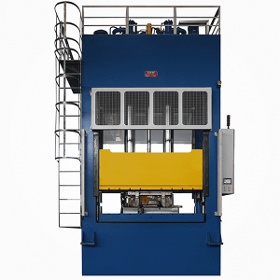

double action conventional hydraulic press (top effect)

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

double action conventional hydraulic press (top effect)

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ballistic composites are the ultimate point of our experience and knowledge on thermoset presses and production systems. product, mould, process, press, automation, hot oil or electric heating or oil or water cooling… whichever model is suitable for you and your product, we can give you the whole system on a turnkey basis. We have a serious place in ballistic composite systems, which is a small and very special market in the world. Our references are proof of that.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Cold crushing of materials leads to positive structural properties. This process requires high tonnage. high tonnage presses require high strength values, less flexibility and maximum rigidity. It is not only necessary to have a high press force, but also to work quickly and quickly. High forces and speeds bring large hydraulic systems and heavy mechanical disruptions. Their safe and smooth control is the most important part of your press. If the press mechanics is not designed correctly from the beginning with its hydraulics and automation, very serious design errors that will occur in the future can cause very serious costs in these presses. Please call us for a high tonnage crushing press, we are ready to serve you with 56 years of experience.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

In processes which requires single effect, Ozkoc offers variety of solutions between 70 to 7000 tons with extractors or complicated solutions with mold core in case of need. Please contact our specialists for choosing most suitable Hydraulic Press specifications for your production.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

In case of need for high quantity production with multi deep drawing operations, Ozkoc offers 2 different solutions. Hydraulic Transfer Press Hydraulic Triple Action Press Advantage of triple action to double action press is on one mold and one hydraulic press, material can be deep drawn 2 times in a row without any additional workload. Its most suitable for where height is much bigger than material diameter such as fire extinguishers, car-truck filters and alike.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

For the deep drawing parts which symetrical and deeper than 100 mm, forget about conventional presses. Ozkoc Bottom effective deep drawing presses can provide you faster production with 30% less energy consumption comparing to conventional hydraulic presses. Please dont hesitate to contact our technical speacialist to suggest you the best solution for your production.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quote

DERYA M.D.M SAN. VE TIC. A.S / GLASSYMOULD®

Turkey

Manufactured out of Special Aluminum Alloy material

Request for a quoteResults for

Presses - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Presses, hydraulic (12)

- Metal industrial presses (6)

- Laser - cutting and welding machines (2)

- Testing equipment (2)

- Control boxes - electric (2)

- Filtering equipment and supplies (1)

- Cutting - machine tools (1)

- SMALL METAL PARTS (1)

- Folding machine tools (1)

- Steels and metals - forming and cutting (1)

- Water treatment, industrial - systems and equipment (1)

- Bicycle components and parts (1)

- Boilermaking, heavy (1)

- Construction - Machines & Equipment (1)

- Crimping machines (1)