- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation control

Results for

Automation control - Import export

MAGMETT METALL INC.

Turkey

Introducing Powder Coating: A Premier Solution for Impeccable Surface Finishing Welcome to our state-of-the-art powder coating facility, where excellence meets innovation. Powered by a cutting-edge Power and Free conveyor system, our facility operates seamlessly under the meticulous control of PLC automation. Dedicated to delivering unparalleled quality, we proudly hold the prestigious Qualicoat and Seaside certificates. These esteemed accolades validate our commitment to producing profiles in all RAL colors, as well as special colors tailored to meet the unique needs and demands of our esteemed customers. At Powder Coating, we prioritize environmental sustainability. In line with our eco-conscious approach, we have consciously chosen organic solvents-free surface chemicals. By doing so, we ensure that our surface treatment processes remain free from harmful substances, safeguarding the environment for future generations.

Request for a quote

ALKIM PETROKIMYA

Turkey

It is a high performance automatic transmission oil produced with modern additive technology to meet the needs of the increased automated control transmission systems, demanding conditions such as today’s high operating temperatures. it was developed far modern automatic transmissions where GM Dexron or Ford Mercan specifications are specifically requested.

Request for a quote

YALCIN GROUP

Turkey

Our magnet control rectifier product is produced as 220 VDC or 120 VDC for magnet lift devices. Application powers vary between 3 kW and 60 kW. The magnet control rectifier can be easily operated by the user with the remote control Start-Stop remote control, and lifting and dropping operations are performed safely. In addition, the inductive energy released during closing (demagnetism) is eliminated by a special damping snubber circuit, ensuring smooth operation of the on-off contactor. Magnetism and Demagnetism are done with automation-controlled control on the rectifier panel, On-Off and Reverse-Direct voltage application technique. In addition, due to the buffer charging feature of the rectifier, the battery group can be connected to the desired Ah capacity, ensuring healthy charging and at the same time ensuring uninterrupted safe operation of the iron lifting magnet in case of power outages. Iron removal rectifier (magnet rectifiers), special type input and output upon request.

Request for a quote

EDIT ELEKTRONIK SIST SAN VE TIC LTD STI

Turkey

Machine automation and control console Electrical equipment Cabinet 2mm mild steel body Durable welded design IP66 protection for external applications Locked and hinged doors Special carrying and fixing accessories Epoxy-Polyester powder paint Primer painting for external applications Zinc coating solution against corrosion and oxidation. PEM screw-nut driving solution for ease of assembly Shock absorber covers Mounting trays Production in special sizes

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACS Series compact system press feeding machines consist of 600 and 1600 coil width, 2 and 10 mm of sheet metal thickness, between 6.000 and 15.000 kilograms of coil weight capacity feeder, straightener and decoiler. 11-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

NOVOSIM

Turkey

This system provides automated quality control at the end of the production line. It is designed for real-time defect detection, automated inspection, and quality assurance. It serves as a critical tool to enhance product quality and reduce the production of defective items. The system features an easy-to-use interface and can be quickly set up. Personnel on the production line can efficiently operate the system and perform quality control procedures after a short training period. Data collected through sensors is used to perform real-time analysis on product dimensions, shapes, colors, and other defining characteristics. These analyses enable the detection of any defects and prompt actions to be taken.

Request for a quote

SLIDING DOORS AND WINDOWS

Turkey

schuifdeur, schuifraam, upvc ramen. pvc deuren. aluminium rolbesturing. Met 17 jaar ervaring in deze branche bedient Fettahoglu Pvc de beste pvc-ramen en -deuren voor onze nationale en internationale klanten. Met CNC-machine en deskundige werknemers staan we klaar om u en uw klant van dienst te zijn.

Request for a quote

SLIDING DOORS AND WINDOWS

Turkey

schuifdeur, schuifraam, upvc ramen. pvc deuren. aluminium rolbesturing. Met 17 jaar ervaring in deze branche bedient Fettahoglu Pvc de beste pvc-ramen en -deuren voor onze nationale en internationale klanten. Met CNC-machine en deskundige werknemers staan we klaar om u en uw klant van dienst te zijn.

Request for a quote

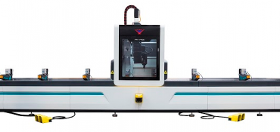

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4420 is a 4-axis servo-controlled machining center that is designed to perform drilling, grooving, notching, taping, sawmilling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin-walled steel profiles. Efficient and economic processing on the three sides of the profiles is possible with this fully automatic machining center. General Features: • It is designed to make operations on three surfaces of the profiles such as a hole, slot, corner relieve, saw cutting, tapping, flow drilling, etc. • CNC automation system providing motion control at 4-axis • Linear type of magazine unit for 11 standard tools and Ø180 mm of the saw blade • Flow drilling and tapping feature by means of encoder spindle (optional) • Automatic clamp recognition and clamp positioning are available • CNC controlled spray tool lubrication system • Pneumatically working 4 pcs of clamps for gripping the workpiece

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

arn Fixing Machine - Steam Master AISI 304 quality Cr-Ni body. High efficiency vacuum pump. Hydraulic and safe cover system. Indirect heating system. (Electric or Steam) Different loading apparatus (Caglik, Pan or Pallet) Optional automatic loading systems. Machines with varying capacities according to customer demands. (150-1500 kg / charge) Homogeneous heat and moisture distribution in all yarns. Fully automated control program that provides repeatable fixation requirements. -0.8 – 2 Bar Working Pressure. Maximum operating temperature of 135 °C. (142 °C with special production) Maximum security. (electronic, electro-mechanical and mechanical) Monitoring and reporting with central network networks.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Thermal oil boilers are used for meeting thermal energy requirement safely and effectively over 300-320°C degree. Thermal oil systems provide to reach higher temperature that heat transfer liquid cannot reach in the atmospheric pressure. The heating surfaces of the hot oil boilers of Eralp Boiler are manufactured in accordance with DIN 4754 and in spiral bent boiler pipes that are nested in a suitable style. There is no stagnant point in the hot oil circulation. Oil speeds are also secured by flow control systems. As Eralp, we can produce steam boilers working with Liquid fuel, Biomass, Gas and Solid fuel. We increase the system efficiency with the economizer to be added to the back of the boiler. We use steel drawn pipes in accordance with EN 10216-2 norm of European origin in our production as a standard. The system is secured with the automation and PLC control systems used. Energy loss is prevented by reducing the thermal bridges in the insulation.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

This is Yeniada Makina's printed roll slitting machine for big rolls into small rolls. It has automated tension control, 7" control panel, automated edge control , airshaft roll holder, meter counter.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

2 Color Online printing machine for production lines. Servo motor driven , SIEMENS 7" Touch Control Screen and PLC controlled automation systems added. Ink pump & Ink tank for each color group included .

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

Yeniada Makina’s folding machine , used to fold printed rolls into new roll Machine features: Working speed up to 150 meters per minutes Meter Counter Automated tension control system Airshaft roll holder 7″ touch control panel Edge control system Custom roll width design

Request for a quote

NOYA BILGISAYAR SISTEMLERI LTD.

Turkey

New E-Life EPC-415 is offering high performance Celeron J1900 Quad-Core processor, 15” Projected Capacitive (PCAP) Touch Screen and rich I/O ports in a robust but stylish aluminum die cast chassis. EPC-415 has industrial grade 15” TFT LCD Display with 350 cd/m2 brightness to ensure smooth user experience in all industrial environment. Its specially designed Projected Capacitive Touch Sensor with 4 mm total thickness provides durability and sensitivity as well as glove support to ensure seamless touch screen experience at all environments. EPC-415 has rich I/O port structure including 4xRS232, 1xRS485, 2xGibabit LANs, 2x USB 2.0, 4x USB 3.0, Digital I/O and a remote ON/OFF switch to provide easy operation in case device was panel mounted in a housing. With all these enhanced features and stylish design, EPC-415 is an ideal solution for many different applications like industrial automation, HMI, Machinery Control, IoT, Industry 4.0, Smart Factories, Smart Building and Smart Retail.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Automation control - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Cutting - machine tools (3)

- Terminals, computer (2)

- Aluminium and aluminium alloys (1)

- Cutting, plastics - machinery (1)

- Electric roller blinds (1)

- Electromagnets (1)

- Flexography - machines (1)

- Folders, paper (1)

- Folding machine tools (1)

- Import-export - oil (1)

- PVC windows (1)

- Power stations, oil-fired (1)

- Testing equipment (1)

- Textile finishing (1)

- Textile finishing - machinery and equipment (1)

- Textiles - finishing, printing and dyeing machinery (1)

- Voltage stabilisers (1)