- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic line

Results for

Automatic line - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Conveyors that we use for painting plants and various transfer lines are the most important parts of the automatic systems. Commonly used Webb, Kardan and Power & Free type conveyors are projected and put into used by us. Semi-automatic conveyor lines are also produced for lower production capacities.

Request for a quote

ATOM KARINCA LASER

Turkey

We produce our customers orders with a 60-meterlong automatic conveyor line and 8x3x2.5 meters electrostatic powder coating box. ATOM KARINCA completely fulfills all the necessary processes and offer perfect surface quality. We perform electrostatic powder coating according to RAL color codes and surface types. Our heat box unit temperature is between 180-200 Celsius So, painted surface that becomes an integral part of the metal part. After final inspections, the materials are checked in the quality control unit, packaged (DIN standard), and then shipped to the customer.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

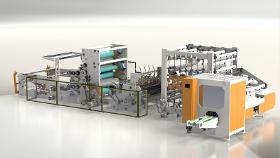

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed. Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities. Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups. Double Embossing Technique: Ability to wrap products with two different embossing patterns. High Efficiency: Fast and uninterrupted production capacity. Flexible Production Options: Ability to process paper of different sizes and thicknesses. User Friendly Design: Easy operation and adjustable features.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

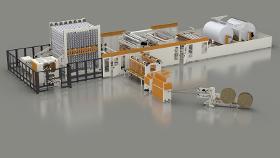

Non-Stop production Line is a technology that revolutionises the production of toilet paper and kitchen towels by offering a continuous and uninterrupted production process. This line significantly improves the efficiency of the production process and product quality with its high speed and continuous operation capability. With its non-stop production capability it enables an impressive production capacity to be achieved, especially in large-scale production facilities. Non-Stop Toilet Paper Line is an industrial line that can operate continuously and produce rolls (toilet paper, kitchen towel) without interruption in production. It maximises the efficiency of the production line and enables more production with less workforce. Continuous operation feature means time and cost savings in production processes. Continuous and Non-Stop Production: Continuous production capability at high speed.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

30m/ min Core maker Machine used in the toilet paper industry, plays a critical role in the production of toilet paper and has certain technical features. This machine is capable of high-speed operation, which ensures the ability to produce large quantities of toilet paper cores. It also has a structure that can adapt to different sizes of toilet paper and kitchen towels, which allows the production of various types of toilet paper. The machine is compatible with different bobbin types, making it suitable for the production of soft or hard tubes. Equipped with automatic control systems, this machine enables continuous and efficient operations. The 30M Corer Machine is a machine used in the production of cores and is widely used especially in the paper converting industry. The use of this machine offers great advantages for toilet paper manufacturers. Here is more detailed information on where the 30M Corer is used.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Toilet paper production requires effective and efficient machines, especially in cases requiring high volume production. The 4 Channels Log Saw Toilet Paper Cutting Machine is an advanced and high capacity cutting machine that plays an important role in toilet paper production processes. Due to its four separate channels, this machine cuts four different toilet paper rolls at the same time which significantly increases the production capacity and efficiency. With its advanced technology and high-speed processing ability, it has become an indispensable part of large-scale toilet paper production facilities. The 4 Channels Log Saw Toilet Paper Cutting Machine is a highly efficient industrial machine designed to cut long and continuous toilet paper rolls (logs) to specified dimensions. This machine, which has four separate cutting channels, cuts four different rolls at the same time, significantly increasing the speed and capacity of the production process.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin Production Machine is an industrial level machine designed for mass production of napkins. Modern napkin manufacturing machines meet high standards in terms of both quality and efficiency and have a wide range of uses. Napkin Production Machine is an industrial machine used to produce napkins from raw paper material. This machine automatically performs the processes of cutting, folding and sometimes printing the paper. The main purpose of the machine is to meet the demand by producing napkins at high speed and continuously. Fast Production Capacity: Continuous and fast napkin production. Multifunctional Operations: Ability to perform operations such as cutting, folding and printing together. Flexible Production Options: Ability to produce napkins in different sizes and patterns. User Friendly Interface: Easy operation and adjustable functions. Napkin Production Machine is used in places such as napkin producing factories and paper processing plants.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Production Line is an advanced technology that offers a high-capacity and efficient production system that occupies an important place in the modern paper production sector. This production line stands out with its ability to produce both toilet paper and kitchen towels at the same time, thus increasing production flexibility and capacity. Equipped with advanced automation features, this line makes production processes faster and more efficient. Automatic (Dual) Toilet Paper and Kitchen Towel Production Line is an automatic production system that can produce toilet paper and kitchen towels at the same time. Thanks to its dual-functional structure, it can produce two different products on the same line and without interruption, which increases both the speed and efficiency of the production process. Dual embossing unit: Ability to produce both toilet paper and kitchen towels.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Loss in weight gravimetric feeder for extrusion lines automatic control, it controlls the haull-off speed and weight per meter of pipes during extrusion process.

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quote

KEDY

Turkey

Manual All controls are made by the operator via the control button. Each crane is controlled by an operator. Semiautomatic H Busbars are an automatic transport system from the unloading area to the loading area. The system is suitable for automatic operation. Transitions between stations are made by operator control. Waiting and immersion times are automatic in the boilers. Automatic operation when necessary, but in case of failure, intervention with external operators, transitions between boilers are made by the operator. Fully Automatic The whole process is controlled from the skada screen. There is no need for an operator at the beginning of the cranes. All boiler chemical controls are made automatically from the skada screen. Transitions between stations are made automatically to unloading stations. It has the possibility of easy maintenance and intervention with remote access. Lifting drive is with chain gear system and it is supported by rollers on the guide rail

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quote

BEMKA CABLE

Turkey

with its 4 automatic lines, BEMKA CABLE has the capacity to produce 2.5M plug-in cables per month. As a plug cable, it serves its customers with 2.5A / 16A HYDROPONIC / 16A EUROPEAN TYPE / 16A TURKISH TYPE products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

Machine is ideal for welding process of PVC plastic profiles at four corners. Fully automatic four corner welding of PVC window profiles at an angle of 90° Welding of a complete window frame or sash in one cycle All profile related welding parameters are individually programmable User-friendly operating system compatible to all optimization programs Parameters are set easily by means of 8’’ LCD color touch screen Automatic line can be made by combining with Cooling Unit (SA 250),Corner Cleaning Machine (CNC 608-610) and Rotating Robot (SA 260) Automatically setting of standard (2 mm) or seamless (0.2 mm) welding options Long time of Teflon using period by means of the roller system Automatically discharging of the frames after welding operation Colored and white profiles selection modes Saving of time by means of practical mold change system Operator safety barrier Adjusting the heat between 0-300°C via electronic thermostat Minimum welding measurement : 400 x400 mm

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

CMS GLASS MACHINERY

Turkey

Automatic glass cutting line comes with automatic loading system and glass breaking table and designed for straight and shapes cutting of float glass using the diamond cutting wheel technology.

Request for a quote

CMS GLASS MACHINERY

Turkey

Automatic glass washing and combining line with hydraulic panel press can assemble and press double, triple or structural (step, facade) insulating glass units.

Request for a quote

ALTUNPACK LTD PACKAGING MACHINERY

Turkey

Liquid filling and packaging machine. Flexible single-use package from 1 to 30 g. Capacity 100 packs per minute

Request for a quote

OMAKS MAKINA LTD. STI.

Turkey

Automatic wafer production lines, horizontal flow pack machines and automatic feeding systems for many kind of confectionery products like, chocolate bars, wafers and cakes.

Request for a quoteResults for

Automatic line - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Copper wires and cables (5)

- Toilet paper (4)

- Double glazing (2)

- Napkins, paper (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Food Industry - Machines & Equipment (1)

- Bending - steels and metals (1)

- Blades for saws and cutting machines (1)

- Buckets and grabs, crane (1)

- Electric cables (1)

- Paint spray guns and accessories (1)

- SWEETS (1)

- Testing equipment (1)

- Welding robots (1)