- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- formed sheets

Results for

Formed sheets - Import export

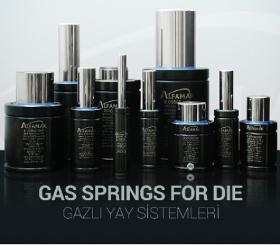

TEMAS GROUP EXPORT PARTNERS

Turkey

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

BOSPORAS

Turkey

Roll Forming Lines can produce a wide range of products. Some of the products you can produce using roll forming machines; Highway Acoustic Barriers, Gypsum Profiles, Cable Trays, Scaffolding profiles, Storage rack profiles, Market shelf profiles, Suspended ceilings, Guard rails, Trapezoidal profiles, Shutters, Hose and duct clamps.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YENIMAK MAKINA

Turkey

Maximum Mould Size : 850x650 mm Maximum Forming Area : 820x620 mm Maximum Cutting Area : 820x620 mm Positive Forming Height : 160 mm Negative Forming Depth : 160 mm Maximum Sheet Width : 910 mm Minimum Sheet Width : 400 mm Upper Heater Heating Power : 71 kW Lower Heater Heating Power : 71 kW Continuous Power Consumption : 142 kW Total İnstalled Power : 225 kW Vacuum : 250 m³/h Dry Running Cycle : 60 cycle/dak Weight (approx.) : 14000 kg Length : 10300 mm Width : 2800 mm Height : 3000 mm Required Compressor : 8 m³/min Required Cooler : 50000 kcal

LAZERSAN LAZER KESIM BUKUM SAN.TIC.LTD.STI

Turkey

Lazersan supplies precision sheet metal products, components.

Request for a quoteResults for

Formed sheets - Import exportNumber of results

8 ProductsCountries

Company type