- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cooks

Results for

Cooks - Import export

PARSMEGA MAKINA

Turkey

It collects the flour from all exits of the sieve and delivers it to the flour container via pneumatics. Flour inlets are made with separate flour inlet valves. The valves lower the incoming flour into the spiral part. From here, it is directed to the outlet section via a spiral. Since the flour is covered with hair on the spiral, dust formation is prevented. There are ventilation holes at a certain point in this closed sheet metal. The spiral legs are made of rectangular profile. The helix of the gearmotor is located on the side of the outer body and is fixed to this side with the motor stand. There are rubber inspection covers on each flour flap.

Request for a quote

PARSMEGA MAKINA

Turkey

It is used for vertical transportation of wheat. It consists of two parts: lower and upper heading. Pipe length is adjusted according to the building height. The drive of the elevator is made by the reducer motor located on the upper head. The motor stand has slides and can be easily adjusted to enable shaft center adjustments. Belt tension is provided by the tensioning mechanism connected to the bearings.

Request for a quote

PARSMEGA MAKINA

Turkey

Valves are generally used to control the product flow under flat-bottom silos with tunnel systems, chain conveyors and conical-bottom silos. It has a wide application area with its galvanized steel structure.

Request for a quote

PARSMEGA MAKINA

Turkey

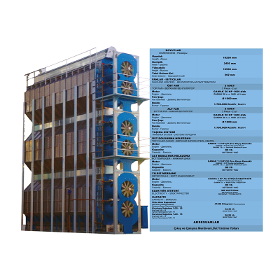

8.8 & 10.9 quality very durable decromat 500 armored bolts were used to connect the sheets and increase the durability of the silos. Special insulation has been applied to the silo sheets and ceiling cone head connections to ensure air and water tightness.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the classification of the ground product in a clean and orderly manner, thanks to the freely swinging body and the crates of different sizes in each passage within the body. After being sieved and homogeneously separated, the product in various proportions is automatically directed to the outlet channel through the channels in the frame, the channels between the frame and the channels in the main chassis, and is discharged outside the outlet pipes through control pipes. The surfaces of the cases are covered with formica. The outer covers of the passage are insulated, thus preventing flour particles from leaking out. The product enters the first case as one or two batches from the entrance above the passage and flows along the passage height of all cases. By placing spacers between the frames of the main frames, the product output volume increases, accumulation

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided as a curtain between the roll rolls.

Request for a quote

PARSMEGA MAKINA

Turkey

CAPACITY: Varies between 12 tons/hour and 20 tons/hour, depending on the product to be bagged and the desired tolerance. (It is guaranteed to work with a capacity of 15 tons/hour for flour or products of the same character, with an average error margin of +-50gr. per sack.) SET VALUE: set value can be programmed individually by the user. WEIGHT DISPLAY: The weight display screen has 4 digits. FAST - SLOW CYCLE: There are two programmable set values in the system. And the filling kilos for these values can be entered separately. The slow speed transition program adjustment is automatically determined and adapted by the system to provide the most precise and fastest weighing. Optimum speed adjustment is made automatically according to the weighed flour type and silo level. TOLERANCE: Upper or lower tolerances can be programmed individually. If the weighing result is outside these tolerances, flour is not loaded into the sack from the weighing bunker without

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the cleaning of barley, rye, cracked wheat, vetch and black grass seeds in wheat. It performs this cleaning thanks to the sphere-printed sheet metal attached to the body with screws. As this sheet rotates, it separates the materials that will adversely affect the grinding in the incoming product, according to the diameter of the sphere pressure and the spiral angle given by the adjustment lever. The cleaning process takes place at 36 rpm. The trieur machine consists of four main parts, these are: Wheat input Wheat cleaning part Clean wheat output Broken wheat output

Request for a quote

PARSMEGA MAKINA

Turkey

Stone separation machines are used in flour factories to separate materials such as stone, metal, glass and soil in wheat that have a specific gravity different from wheat. It is an indispensable machine especially for dry system cleaning units. Stones and similar substances can easily enter the wheat from nature. If these substances are not separated from the wheat, the flour or ash content will be high as a result of grinding. This is also an undesirable feature.

Request for a quote

PARSMEGA MAKINA

Turkey

Hulling machine is used to peel wheat. Separates foreign substances such as dust, sand and small seeds in wheat. It crumbles the soil and other adherent grains attached to the wheat grains, reduces the bacterial load, and cleans the wheat from bacteria and insects. It also enables the separation of grains that have not been separated from the spike. Thanks to this new model, a smaller design but higher capacity has been achieved compared to our old model. Instead of flat pallets in the previous model, cast pallets were used in this model and the product contact surface was increased. In this way, a more efficient peeling process is achieved.

Request for a quote

PARSMEGA MAKINA

Turkey

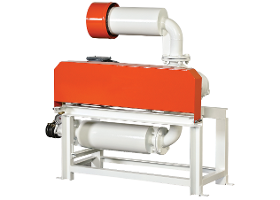

It enables the broken and crushed product in the rollers to be transported to the sieve and other machines. It absorbs the broken or crushed product through steel pipes and distributes it to cyclones and ecluses. Consists of outer body and fan part. The outer body has a snail structure. The internal fan is designed with paddles according to capacity. It is mounted coupled to the engine located on the outer body. The fan inside the body rotates at high speed and provides air suction and pressure. Since the fan is specially balanced, it does not cause vibration or noise. In addition, since the outer body is placed on the main chassis on special rubber wedges, it does not cause vibration on the chassis.

Request for a quote

PARSMEGA MAKINA

Turkey

Blower pumps are used in mill systems to meet the air required by the supersonic filter and to transport products vertically and horizontally.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PARSMEGA MAKINA

Turkey

It ensures the cleaning of barley, rye, cracked wheat, vetch and black grass seeds in wheat. It performs this cleaning thanks to the sphere-printed sheet metal attached to the body with screws. As this sheet rotates, it separates the materials that will adversely affect the grinding in the incoming product, according to the diameter of the sphere pressure and the spiral angle given by the adjustment lever.

Request for a quote

PARSMEGA MAKINA

Turkey

Radial scanning machine is used to separate low density substances from high density grain products such as wheat, barley, corn and similar. Separates foreign substances such as dust, sand and small seeds in wheat. Wheat entering the machine from the wheat inlet is filled into the vibro feeder and distributed smoothly across the width of the air duct. Here, in the horizontal aspiration channel, the product is separated from low density materials through its double adjustable wall. The fan of the radial scanning machine is mounted on the main body through bearings. The outer body is made of sheet metal, and the foot part and the outlet nozzle located on the foot part are mounted on the body.

Request for a quote

PARSMEGA MAKINA

Turkey

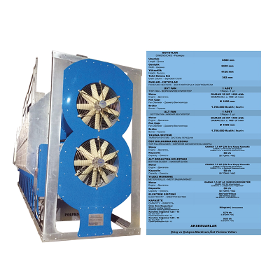

Aspirators have high air suction power and are manufactured in different sizes and engine powers. Aspirators with different capacities; It is frequently used in the aspiration of cleaning machines in Flour Factories. This type of aspirators are also used for the aspiration of low capacity semolina purifiers. They operate at a flow rate of approximately 300 m3/hour. They are generally used in small capacity cleaning units.

Request for a quote

PARSMEGA MAKINA

Turkey

The air duct is made of sheet metal construction. It is possible to make the desired air setting with air valves. Thanks to the mica glass, the cleaning process of the product can be clearly seen. The air duct is used to separate foreign substances that are lighter than the product with the help of air. It is mounted in front of the garbage separator and at the outlet of the peeler. The feeding table located at the product entrance ensures homogeneous goods flow throughout the channel. The rear curtain, which is moved throughout, allows the duct cross-section to be adjusted as desired by means of adjustment bolts. This precise adjustment of the air speed in the duct ensures that the light substances in the grain passing through the duct are separated in the desired amount.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the retention of dust and other light substances in the air coming from the cleaning machines. When the air containing dust coming from the dust aspirator is given tangentially to the cyclone, the dust in the air loses its speed as a result of cross-sectional expansion and falls by gravity, while clean air is discharged. Thus, the environmental impact of the air released outside the factory is minimized.

Request for a quote

PARSMEGA MAKINA

Turkey

In flour and semolina factories, it ensures rapid mixing of the product with water and helps shorten the tempering time. Their rotors consist of steel pallets. It is an effective machine in peeling as the grain moves by being squeezed inside the machine.

Request for a quote

PARSMEGA MAKINA

Turkey

IT IS A MACHINE THAT ENABLES BREAKING GRAINED PRODUCTS TO THE DESIRED SIZE. FEATURES: TWO-DIRECTIONAL FEATURE. DYNAMIC AND CYTATIC BALANCED STRONG ROTOR POSSIBILITY TO GRIND RAW MATERIALS WITH 0.2-0.8 kg / dm3 DENSITY ELECTROPNUMATIC DEFLECTOR QUIET OPERATION 90-93 dB EASILY CHANGEABLE HAMMER AND SIEVE SYSTEM COVER WHEN MOTOR CURRENT IS GIVEN SECURITY SYSTEM THAT LOCKS LARGES, TWO-WAY WORKING POSSIBILITY, POWERFUL AND LONG LIFE BEARING BEARING SYSTEM HEAT TREATMENT HARDENED HAMMER AND HAMMER BAR SHAFT

Request for a quoteResults for

Cooks - Import exportNumber of results

124 ProductsCompany type