- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas welding

Results for

Gas welding - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Argon-arc welding Electric arc welding Gas metal arc welding Arc welding"

Request for a quote

NOVELTY STEEL

Turkey

Aluminium fabrication plays an essential role in metal fabrications for a variety of industries. The metal’s light weight, corrosion resistance, and ductility make it ideal for many applications from automotive parts to medical devices. Aluminium isn’t always easy to work with. The appropriate practices and equipment is necessary if you want to avoid welding defects or damage. The choice of alloy, welding gas and joining method can all have a significant effect on the quality of finished products. Due to aluminium’s unique characteristics, aluminium fabrication differs from the other metals. Low weight density of aluminium is common knowledge which brings various advantages and disadvantages in the fabrication. Although aluminium has a weaker mechanical properties, it still possesses higher strength to weight ratio compared to stainless steel and carbon steel in various applications.

Request for a quote

BASAK LAZER

Turkey

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

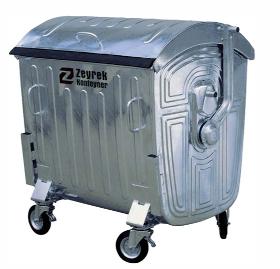

ZEYREK CONTAINER

Turkey

770 LITER METAL GARBAGE CONTAINER Body and base bent from single piece of galvanized sheet. Strength is increased by pressing the body and sides. Body sheet thickness is 1,5 mm. Cover sheet thickness made of 1,20 mm, considering its lightness. Cover hinges ensure that cover is fully opened and closed. The wheel connection sheet is 3 mm. Container lifting arm sheet is 3 mm. Container lifting arms is made of produce from 16 mm steel. Container arms are mounted to the body with 8 steel bolts. The wheels are 150x45 in size. All 4 of the wheel rotate 360 degrees, 1 of them has a brake. Garbage container is produced according to the garbage truck lifting system. The our container is welded with completely slag-free gas arc welding. All materials used in our container are first quality and TSE certificied.

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L-Dimensions: 890 x 1350 x 1440 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable for garbage truck lifting systems. - Cover movement is coil spring. - There is 1 stop mechanism on the lid.There is lastic profile on the lid mouth. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All 1100 containers are fully produced under the EN840 compliant, to ensure the waste bin is compatible with customers requirements, such as trunnion and comb bar lifting devices

Request for a quote

ZEYREK CONTAINER

Turkey

Body and base bent from single piece of galvanized sheet. Strength is increased by pressing the body and sides. Body sheet thickness is 1,5 mm. Cover sheet thickness made of 1,20 mm, considering its lightness. Cover hinges ensure that cover is fully opened and closed. The wheel connection sheet is 3 mm. Container lifting arm sheet is 3 mm. Container lifting arms is made of produce from 16 mm steel. Container arms are mounted to the body with 8 steel bolts. The wheels are 150x45 in size. All 4 of the wheel rotate 360 degrees, 1 of them has a brake. Garbage container is produced according to the garbage truck lifting system. The our container is welded with completely slag-free gas arc welding. All materials used in our container are first quality and TSE certificied.

Request for a quote

ZEYREK CONTAINER

Turkey

-Volume: 660 L -Dimensions: 680 x 1150 x 1135 mm -Weight: 68 KG ( +/-5%) -Body sheet thickness is 1,50 mm. -The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. -Lifting arms are suitable for garbage truck lifting systems. -Container lifting arms are made of 32 inch. -Material: Galvanized Steel -Wheels: 4 rubber 150*45 in size. -Temperature resistant: 30"C to +8O°C -4 of the wheels rotate 360 degrees and 2 of them has a brake -Wheel connection sheet is 4 mm. -Our containers are welded with slag-free gas metal arc welding. -All of our products used in our containers are of first quality and TSE certified

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L - Dimensions: 930 x 1200 x 1390 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable far garbage truck lifting systems. - Container lifting arms are made of 32 inch. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - AII of our products used in our containers are of first quality and TSE certified 660 L and 770 L options are available. Production can be made according to the desired sheet thickness.

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L - Dimensions: 950 x 1200 x 1390 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - Lid is plastic lid. ( Green or other color ) - Lifting arms are suitable for garbage truck lifting systems. - Container lifting arms are made of 32 inch. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All of our products used in our containers are of first quality and TSE certified 660 L and 770 L options are available. Production can be made according to the desired sheet thickness.

Request for a quote

ZEYREK CONTAINER

Turkey

- Volume: 1100 L-Dimensions: 890 x 1350 x 1440 mm - Weight: 94 KG ( +/-5%) - Body sheet thickness is 1,50 mm. - The cover sheet is made of a 1,20 mm sheet, considering it's lightweight. - Lifting arms are suitable for garbage truck lifting systems. - Cover movement is coil spring. - There is 1 stop mechanism on the lid.There is lastic profile on the lid mouth. - Material: Galvanized Steel - Wheels: 4 rubber 200*50 in size. - Temperature resistant: 30"C to +8O°C - 4 of the wheels rotate 360 degrees and 2 of them has a brake. - Wheel connection sheet is 4 mm. - Our containers are welded with slag-free gas metal arc welding. - All 1100 containers are fully produced under the EN840 compliant, to ensure the waste bin is compatible with customers requirements, such as trunnion and comb bar lifting devices. Production can be made according to the desired sheet thickness

Request for a quote

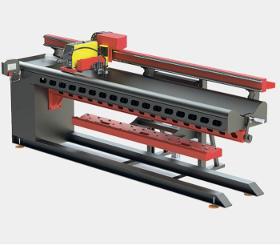

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

There are hydraulic pressing clamps in the fixture equipment of system. The workpiece is both made spot welding by means of clamps and prevented distortion due to heat during welding. Separate control lever is used as to be put to rear of piston for each piston.Also there is a pressure relief valve on each control lever. Thanks to pressure relief valves the critical pressure is brought to the desired pressure and the compression of the material in desired strength may be achieved A lock valve is connected to each hydraulic cylinder after the tightening process and during the welding operation, the material is prevented from being retracted and opened due to heat input. Reverse deflexion may be done on the frame thanks to the control units in the clamp mechanisms. 1 inert gas arc welding machine will be used for spot welding process.( it will be supplied by the purchaser)

Request for a quote

ONDERWELD WELDING EQUIPMENT

Turkey

We have all kinds of MIG torches swan necks

Request for a quote

FHM METAL ISLEME

Turkey

We can produce molds in our press machine, taking into account the number of production, and we can prepare the order you want in the dimensions. With our gas metal and teak welds, we can produce quality welds for you.

Request for a quote

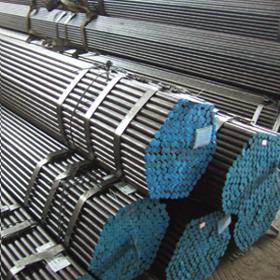

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CERM-EX TECHNOLOGY INDUSTRY AND TRADING INC

Turkey

We have been providing a full range of steel fabrication services for our clients which includes Top International Contractors and Process Manufacturers. Our fabrication facility stands at 45,000 m2 of land area with welding lines, CNC Plasma/Gas cutting machines, MIG/MAG Welding, Cold Rolling machines, Milling equipment, shot blasting and sandblasting, painting and drying and corrosion protection machinery.With the help of our comprehensive machinery, experienced technical team and quality system our fabrication process becomes defect-free

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quoteResults for

Gas welding - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Dustbins, waste bins (7)

- Laser - cutting and welding machines (4)

- Steels and metals - welding and brazing (2)

- Welding work - steels and metal (1)

- Aluminium alloys (1)

- Autogenous welding machines (1)

- Boilermaking, heavy (1)

- Metal structural work (1)

- Pipes and tubes, stainless steel (1)

- Pipes and tubes, steel (1)