- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- technical productions

Results for

Technical productions - Import export

LAVELLA

Turkey

Special water saving aerator is used in our faucets. (Foam flow, Lime Crusher) A filter is recommended at the entrance of the flat as it will overcome the damage of any kind of pollution that may occur in the installation. Warranty certificate and invoice are sent in a box for all our products. Battery Technical Dimensions Battery spout length 129.50 mm Battery connection threads 3/4 ”1/2” Ideal work research 34 Bar Our products are made of 1st Quality Brass material. 5 years warranty. Water and pressure testing achieved 100% success in all of our products. Our products are made of healthy materials. Our products are high quality chrome plated

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

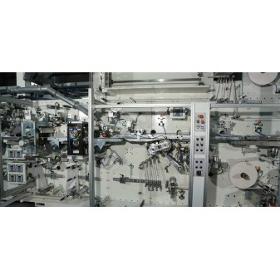

Main Technical Data Production Speed Up to 1000 pcs/min Production Linear Speed 280 m/min max Efficiency 85-90% Product Width (min-max) 70-115 mm w/o wings, up to 165 including wings Product Length (min-max) 180-320 mm Required Air Pressure 6 bar Noise Lower than 90 dBa Basic Machine Features • Top sheet with NW side barriers • Fluff core with short ADL layer • Core anatomic shaped according to customer design • Core embossing according to customer design • Back sheet • Release tape glued on line • Edge sealing & contour cut out according to customer design • Wing tape glued on line Optional Machine Features • Thermo sealing for three pieces top sheet • Videojet printing on ADL • Individual easy wrap fold • Pouch tape • Bypass for straight product

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Adult Diaper AD−250 Main Technical Data Production speed Up to 250 pcs/min Production linear speed 200 m/min−max Efficiency 85-90% Product width (min−max) 480-800 mm Product length (min−max) 710-975 mm Required air pressure 6 bars Required air flow Approx. 8,000 Nl/min Noise Lower than, 85 dBA Basic Machine Features Full servo technology Electronic job change High quality multi-zone forming system with 2D/3D core design Inline & stand alone unwinders Automatic splicing units “ZERO SPEED” Automatic web guiding systems Full feature product User-friendly HMI panel Bi & tri-folding systems Horizontal stacking & counting system Advanced QCS system Safety measures conforming to “CE” standards Optional Machine Features Waist band application Long life carbide die cutters Dual core design

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Main Technical Data Production speed Up to 600 pcs/min Production linear speed 300 m/min−max Efficiency 85-90% Optional Machine Features Low waste side panels application Front ears application QCS vision system Product width (min−max) 250-380 mm Product length (min−max) 370-600 mm Required air pressure 6 bars Required air flow Approx. 6,000 Nl/min Noise Lower than, 85 dBA

Request for a quote

BASAL TECHNICAL TEXTILES

Turkey

Hotmelt Lamination is the method of bonding two different materials such as Film, Spunbond, Spunlace, Metalize, Towel, etc. with hot glue. Fabrics, films, and glues used in Hotmelt Lamination can be in different features according to the intended use of the product. Hotmelt lamination is performed to increase the product’s technical performance, diversify its functions, add an aesthetic look, and provide other additional features such as liquid and airtightness, toughness, endurance, etc. Areas of Use Medical: Hotmelt lamination technique is used in production of products such as tablecloths, surgery covers, gowns, for companies that manufacture medical sets. Promotion: It is used in products such as bags or dress covers. Home Textile: It is used in products such as tablecloths, wardrobes, white goods covers, etc. Insulation: It is used for maintaining the moisture balance inside as well as to provide heat, water, noise insulation

Request for a quote

BASAL TECHNICAL TEXTILES

Turkey

Fabrics, films, are used in lamination have different properties according to the intended use of the product. The method of melting plastic raw materials under pressure and temperature and then letting them flow onto the surface of the material to be coated is called Coating-Plastering. Unlike hotmelt lamination, glue is not used in the Coating- Plastering technique. Fabrics and films used in Coating-Plastering may have different properties according to the product’s intended use. Coating-Plastering is performed to increase the product’s technical performance, diversify its functions, add it an aesthetic look, and provide other additional features such as liquid and airtightness, toughness, endurance, etc. Areas of Use Medical: It is used in products such as tablecloths, surgery covers, and gowns.. Promotion: It is used in products such as bags and dress cover.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Technical productions - Import exportNumber of results

6 ProductsCompany type