- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal sheets

Results for

Metal sheets - Import export

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

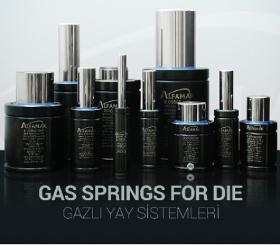

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener machine for having perfect straightening results and without damage on sheet metal surface. Our coil straightener machines provide to have working possibility with high speed and precision sheet metal straightening results during press feeding. We have as alternative for coil straightener machine standard models. And we design and provide for different request specific coil straightener machines. We supply our coil straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener machine solution.

Request for a quote

SEFINE TEKNIK MAKINE

Turkey

Dimensions Thickness: 5 mm up to 150 mm Width: 1000 mm up to 3050 mm Tolerances: EN10029, ASTM A6, ASTM A20, ASME SA6, ASME SA20, DIN 1543, JUS. C. B4. 110 UT Tests: EN 10160:1999 Z quality requirements: EN 10164:1993 Weight and terms of supply: Maximum plate weight is 8 tons 9,5 tons can be produced upon request Flame cutting between 40 to 150 mm thickness Surface conditions: rolled, sandblasted and primer coated High tensile strength plates according to DIN standards can be produced with hardness at - 50 degrees and yield strength at high temperatures, whichever is preferred in other standards.

Request for a quote

FLEXTAB

Turkey

C ceiling profile. Plasterboard profiles for a variety of applications for new sections used in structures. C profiles ceiling wall C-profile chamber by making use with calls. They are obtained by giving the shape of the galvanized. These profiles are thicknesses ranging from 0.5 mm to 0.4 mm. Thickness: 0.4 mm Length: 3 m. The Packaging 12 pcs / package.

Request for a quote

ARMAN ENERJI ELECTRIC CO.

Turkey

he switching element is designed to be used in accordance with SCK can be manufactured in any size. In addition, sled, trailer towing, and using a mobile pavilion is made of sheet metal. SCK substations consists of 3 parts.; O.G. switching section UK. Section A.ğ. section All are manufactured using galvanized steel sheet metal kiosks. Isolation by using sandwich panels can be made according to customer desire. SCK RMU lu s in particular transformer size and weight as a big advantage centers will be preferred because it provides. Thanks to the prefabricated modular structures may be established by larger centers. But the pavilion size increases with increasing system costs compared to concrete kiosks. Properties Compared with concrete pavilion allows for ease of transport and assembly is a lighter product. It is designed to be used in accordance with the switching elements can be manufactured in any size SCK.

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Metal sheets - Import exportNumber of results

6 ProductsCompany type