- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- component assembly

Results for

Component assembly - Import export

NOVELTY STEEL

Turkey

Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame or structure. The fabrication process of steel products can be categorized into 5 steps primarily based on the sequence of the task. These are: Steel Detailing Steel Profiling Cutting Bending Rolling Drilling Welding Surface Preparation and Painting Packagin At Novelty Steel, we usually use readily available steel sections that are purchased from the steel mills, together with complementary material such as protective paints and fasteners from other specialist suppliers. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery

Request for a quote

ILK IHRACAT AS.

Turkey

Steeling.net specializes in producing top-tier elevator shaft dividers, consoles, and connecting elements, engineered for durability and precision. Utilizing advanced laser cutting, CNC bending, and welding techniques, we create components that ensure the safety and efficiency of your elevator systems. Our elevator shaft dividers are designed to provide robust partitioning within the shaft, while our consoles and connecting elements facilitate secure and reliable installations. Each product is custom-made to meet your exact specifications, ensuring seamless integration with your existing structures. Choose steeling.net for superior elevator shaft solutions that offer both functionality and long-lasting performance, crafted with meticulous attention to detail.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Asphalt Fiber Granule Additive System is a modern, pre-engineered component assembled in asphalt plants for the introduction of fiber granules into asphalt mix with needed precision and control. These fiber granules play a vital role in strengthening asphalts against cracking, rutting, and other distresses. Fiber granules enhance the durability and performance of asphalt pavements, allowing them to sustain increasing volumes and intensities of traffic without being affected by various harsh weather conditions. The system is critical in the manufacture of high-quality asphalt mixes qualified enough for modern infrastructure. The effect of adding fiber granules into an asphalt mix is reinforcing; much the same way rebar does in concrete. This reinforcement allows such loads to distribute further out in the pavement, minimizing the chances of damage with time.

Request for a quote

TAKE CRAFT MUHENDISLIK TICARET VE LIMITED SIRKETI

Turkey

Innovative Solutions in Electronic Sector At Take Craft Engineering, we have successfully delivered numerous projects in the electronics sector, offering innovative and high-quality solutions tailored to the rapidly evolving needs of the industry. From the production of precise and complex electronic components to assembly and testing services, we provide a comprehensive range of services.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With Polygonmachs you can produce asphalt with efficiency going forward thanks to its 160–200 TPH Stationary Asphalt Plant For large-scale construction projects the ground-breaking Polygonmachs 160-200 TPH Stationary Asphalt Plant is expected to revolutionize the asphalt production industry. This post will examine the special qualities and component assembly method of the 160-200 TPH Stationary Asphalt Plants that set them apart from competing goods on the market. The 160–200 TPH Stationary Asphalt Plant maintains exact control over the production process ensuring that every batch of asphalt it produces meets the highest industry standards. Long-lasting high-quality asphalt is produced as a result of this diligence. By utilizing this cutting-edge technology your construction projects will function more efficiently and effectively. Functionality and Benefits One of its key benefits is its amazing production capacity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALUMINAL YAPI

Turkey

Aluminal A.Ş. produces aluminum frames and construction solutions of solar panels in cooperation with Tecinnova International. In addition to traditional solutions, thanks to aluminum constructions with pre-assembled components, photovoltaic system installations can be much easier, faster, more practical, more reliable and less expensive.

Request for a quote

BACA MAKINE LTD.

Turkey

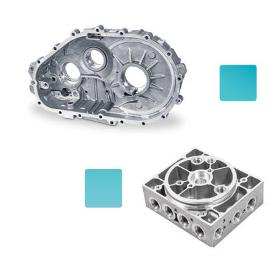

High pressure casting is a process in which molten metal is safely filled into the mold cavity under pressure. High dimensional accuracy greatly reduces machining work. High pressure die castings have a good surface finish, which is a basic requirement for coating. Molds have a long service life, reduce unit part costs, and more complex parts can be produced, thereby reducing the number of components required in an assembly.

Request for a quote

NOVOSIM

Turkey

End-of-Line (EoL) testing devices are used to test the quality of the product after the production process. The purpose of the testing system is to check any visual, audio or other problems that may arise during the installation and assembly of components before they are delivered to customers. Application examples of end-of-line testing systems developed by Novosim include: Rotary systems (transmissions, axles, etc.) Automotive Component Testing Noise and vibration level measurements special systems EoL testing systems are complex systems that generally operate automatically and include a range of sensors, data acquisition devices and testing equipment. Test procedures can be prepared in the form of predefined scenarios by the development team and stored in a database. Different scenarios can be prepared for different test conditions (high speed, low speed, long term, short term, etc.) and then called from the database.

Request for a quote

NOVOSIM

Turkey

End-of-Line (EoL) testing devices play a crucial role in assessing product quality post-production. They are instrumental in detecting any visual, auditory, or operational issues that may arise during component installation and assembly, ensuring that only flawless products reach customers. Novosim's end-of-line testing systems cater to a diverse range of applications, including rotary systems (such as transmissions and axles), automotive component testing, noise and vibration level measurements, and specialized testing requirements. These sophisticated EoL testing systems are designed to operate automatically, leveraging a comprehensive array of sensors, data acquisition devices, and testing equipment. They enable the creation of customized test procedures, which are stored in a centralized database for easy access. These procedures can be tailored to different test conditions, accommodating variations in speed, duration, and other parameters.

Request for a quote

DERYA M.D.M SAN. VE TIC. A.S / GLASSYMOULD®

Turkey

Mould Holder Arms or Complete assembly with components including Pins and Bushings.

Request for a quote

DANNIE.CC TR

Turkey

Embedded payment terminal with a 3.5 inch touch screen and GSMcommunication, certified according to the standards of international payment systems. We carried out a project of serial production of turnkey terminals, including the procurement of components, moulding of cases, components mounting on the board, assembly, firmware and testing of finished terminals. Prior to the launch of the project, a DFM analysis was conducted, which resulted in a redesign of the housing, increased display contrast, a new antenna on a flexible printed circuit board, and optimized BOM. Thus we increased the reliability of the device while reducing manufacturing costs. One of the main aims our developers and technologists pursued was to ensure a tight fit of the display to the body under any temperature and mechanical deformations.

Request for a quote

GEPATEK ELEKTRONIK VE SAVUNMA SANAYI AS

Turkey

SMT and THT assembly with automatic lines. IPC Class 1-2-3 products.

Request for a quoteResults for

Component assembly - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Concrete preparing - machinery and equipment (2)

- Printed circuits (1)

- Testing equipment (1)

- Electronic cards (1)

- Glass manufacturing - machinery and equipment (1)

- Hoists and elevators, construction (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Milling - machine tools (1)

- Payment systems, automatic (1)

- Steel, structural (1)

- Steels and metals - welding and brazing (1)

- Tar and asphalt - construction materials (1)

- Windows, aluminium (1)