- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc processing

Results for

Cnc processing - Import export

ARTI FERFORJE METAL LTD

Turkey

We do also offer Laser Cut with your own designs and variety of choices.

Request for a quote

NOVELTY STEEL

Turkey

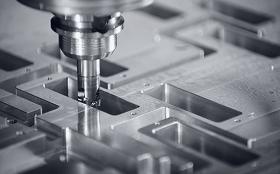

CNC Milling process is highly versatile and capable of producing flat or curved profiles and intricate shapes with a high degree of accuracy and excellent surface finish. Milling machines are a fundamental component in modern machine shops due to their efficiency and capability in shaping a wide range of materials into precise parts and components. Novelty Steel supplies a broad variety CNC milling parts for various applications.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Plastic Mold Industry Sector; It has developed with the widespread use of plastic. Our company, which closely follows these developments, has made many improvements and updates in the field of plastic mold / injection mold. By directing the design process, which is completed with great care, to the machine park, the necessary mold set for mold manufacturing is ordered. The raw material of the incoming mold set is selected according to the product and production type. Quality and efficiency are kept at optimum level in works that require high precision. In addition to injection molds within AYBERKSAN Plastic Mold Industry; ZPL, hot runner, blow mold, rubber press mold and insert mold are also produced. The mold designed in the CAM phase is programmed to be processed on CNC machines. At the same time, processes that require dimensional precision are reviewed. After programming, the mold is processed on the CNC machine.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Aluminium Machining - Your Premier Provider of Proficient Profile Production and Processed Products At Aluminium Machining, we take pride in offering comprehensive services to our esteemed customers. Our expertise extends beyond profile production, as we also specialize in delivering top-notch processed or finished products utilizing the latest CNC and mechanical processing centers. With our state-of-the-art facilities, we guarantee precise cutting up to 5 mm, maintaining a remarkable tolerance of ± 0.1 mm. Our double-head saws enable us to effortlessly execute angled cuts ranging from 350mm to an impressive 12000mm. To further cater to your specific requirements, we possess the capability to conduct drilling, unloading, and die-cutting processes using eccentric presses. Additionally, our proficient team can seamlessly perform CNC milling and unloading processes, ensuring unparalleled precision and efficiency.

Request for a quote

AUROMAK MAKINA

Turkey

It is especially used for cleaning, deburring and degreasing of parts that are too small to be placed in baskets. Parts such as fittings, bolts, nuts and nozzles used in the automotive industry; Coating in the coating industry all the small parts before Unions and fittings parts in hydraulic industry, It is used in the cleaning processes of automat on an darmature parts processed on CNC benches in the metal industry.

Request for a quote

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

Aluminium (Each kinds), Iron (GGG15, 20, 25, 40, 50), Çelik (X20Cr13, WCB, alloyed), Stainless Steel (SS304, SS304L, SS316, SS316L, SS321, duplex, super duplex) materails CNS machinings

Request for a quote

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

Within the Rt Makina Production Facility; With over 10 high-tech CNC benches, it can process complex and sensitive parts that will be manufactured from aluminum, zamak, steel, stainless steel, titanium, magnesium/nickel-based materials in the form of plate, sheet metal, casting and forging in accordance with customer specifications.Machining is a manufacturing method that covers the shaping of the pre-designed and constructed machine element, the manufacturing process of which is determined, by subjecting it to the cutting operation with the specified cutting tools on the machining benches suitable for the manufacturing process.

Request for a quote

NURER MAKINA LTD STI

Turkey

Welcome to the pinnacle of precision manufacturing with our CNC Vertical Process , a revolutionary solution that redefines excellence in vertical machining. As a leading provider of advanced machining solutions, we are proud to introduce our CNC Vertical Process , meticulously engineered to meet the evolving needs of modern manufacturing operations. Our CNC Vertical Process combines cutting-edge technology with unmatched performance, delivering the versatility, efficiency, and accuracy required to stay ahead in today's competitive market. Whether you're producing complex components, intricate molds, or high-precision parts, our machine empowers you to achieve your production goals with confidence.

Request for a quote

SAR-CAM GLASS

Turkey

We offer glass processing by CNC like shaping, cutting drilling works.

Request for a quote

SAR-CAM GLASS

Turkey

CNC processed, shaped, laminated glass with polish ends

Request for a quote

MODULUS METAL

Turkey

Milling Drilling Turning / Boring / Parting Reaming Broaching Planning, Shaping, Slotting

Request for a quote

INO MACHINERY

Turkey

Double Mitre Saw with 500 mm sawblades; customized for aluminium profiles. Second head moving on linear guides via rack&pinion and servo drives. Both heads tilting inside 45 and 90 degrees pneumatically and all in between degrees are adjusted manually. Thanks to the fixed roller conveyor mounted on the secondary head and the manual supports, the profiles are placed on the machine easily and cut perfectly.

Request for a quote

INO MACHINERY

Turkey

Double Mitre Saw with 500 mm sawblades; customized for aluminium profiles. Second head moving on linear guides via rack&pinion and servo drives. Both heads tilting outside 45 and 90 degrees pneumatically and all in between degrees are adjusted manually. Thanks to the fixed roller conveyor mounted on the secondary head and the manual supports, the profiles are placed on the machine easily and cut perfectly.

Request for a quote

INO MACHINERY

Turkey

Double Mitre Saw with 600 mm sawblades and 6 meter cutting length; customized for aluminium profiles. Second head moving on linear guides via rack&pinion and servo drives. Both heads tilting inside 45 to outside 22.5 and 90 degrees all inbetween degrees are adjusted electronically through servo motors and harmonic reducers. The advanced reducer technology that we use on this mechanism allows the servo motors work with zero backlash and maintain the most precise angular adjustment. Thanks to the fixed roller conveyor mounted on the secondary head and the manual supports, the profiles are placed on the machine easily and cut perfectly.

Request for a quote

INO MACHINERY

Turkey

The Double station CNC Panel Working Machinery specialized for machining aluminium composite panels. Also called in the market as ACP panels or ACM panels. The machine first grooves and then cuts the aluminium composite panels by using cutter bits using 2 high speed spindle motors, clamps the panels by vacuuming with a vacuum table and vacuuming pump, extracts the swarf coming out from the panel by a dust extraction system. Thanks to the double station working system, it is possible to load 2 different panels with lengths up to 3.200 mm each and while the machine is processing one of the panels, it is possible to load and offload the other panel in the other station. This machine has a 50% increased capacity compared to the single station machines. All axes are moving on linear guides and moved by servo motors with reducers controlled by a real CNC controller.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing aluminium profiles. Apart from aluminium, it can also process any light alloy profiles with the help of dedicated customized cutters. The bridge carrying the high-speed electro spindle moves on linear guides by the brushless servo motors independently from the drive and processes any shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic reference point tilts up and down automatically according to the machine’s working cycle.4 pieces of profile clamping units are positioned manually by the operator according to the places that the CADCAM decides.

Request for a quote

INO MACHINERY

Turkey

ino XP 8000 is a Gantry type 4 axis CNC machining center for processing profiles. The Maxi-Steel type of extra strengthened machine body has a huge rigidity and flexibility in processing profiles of 350 mm X 350 mm in 0,1 mm / 1-meter precision and 80 mt./min X-Axis speed. With the heavy body and the gantry type of machining bridge, it is possible to process the heaviest aluminium profiles, even hardened steel and stainless steel profiles. The clamping units are moved automatically by the column, and the data is collected from the 3D CADCAM profile machining software that generates G codes from the profile drawings. All profile data can be imported from dxf and dwg files very easily through the software. The machining operations can be programmed by using the ready macros for drilling and milling. The machine has a 7.5 kW 24.000 rpm spindle with adjustable speed for different thicknesses of materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INO MACHINERY

Turkey

ino XP 9000 is a real 5 axis CNC Profile Machining Center working on X-Y-Z-A-C axis independently. Thanks to the CNC controller unit it is possible to make any routing, drilling, milling, notching and cutting operations on the profile pieces in any angle and any position. The machine has a standard size of 7.5 meters and optionally 9.5 meters and 11.2 meters. The pneumatic profile holding clamps are moved by the C column itself and positioned according to the placed that are read from the Profile Machining Software to prevent from collision and for the best grip of the profile piece. The Bi-Rotary head can tilt in A axis +/- 180 degrees and in C axis +/- 325 degrees with the spindle attached 12.0 kW 24.000 rpm with HSK-F63 tool holders. The machine has a tool changer magazine of 10 positions and 1 for the notching and cutting blade. The blades that can be attached on the machine varies from 120 mm to 500 mm max.

Request for a quote

INO MACHINERY

Turkey

CNC profile machining center with economical design cabin moving on X-Y-Z axes. It can work on aluminum and PVC profiles. Specially designed for door and window profiles. It works on profiles with a high-speed spindle moving on a steel body equipped with a CNC controller unit and servo motors. The reference point at the beginning and end of the machine is lifted manually and determines the zero point of the profiles. Profile clamping pneumatic vices are placed on linear guides in 4 units as standard equipment. It works with Uni_Link, customized software for door&window manufacturing, and the clamp positions are displayed on Uni_Link’s own interface. Thanks to the Uni_Link program, Dxf drawings of door and window profiles are exported to the machine HMI. The size of the door profile to be processed is entered, hinge type, lock type is selected, and the machine performs parametric calculations on the profile perfectly.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing on aluminium profiles. Apart from aluminium, it can also process any kind of light alloy profiles with the help of dedicated customized cutters. The bridge that is carrying the high speed electrospindle is moving on linear guides by the brushless servo motors independently from the drive and process any kind of shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic referance point tilt up and down automatically according to the machine’s working cycle.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

We provide plasma - laser cutting services with our modern machinery park.

Request for a quote

MIA MAKINA

Turkey

We are an engineering company in Turkey producing semi-products. Mia Engineering Limited performs design, project, and product analysis to turn your projects into the best quality and efficient product with its experience and technological developments since 2009. We work in the fields of CNC machining, CNC turning, CNC milling, CNC laser cutting, CNC Plasma cutting, and all kinds of machining with our well-trained expert staff.

Request for a quote

MIA MAKINA

Turkey

Mia Engineering Limited performs design, project, and product analysis to turn your projects into the best quality and efficient product with its experience and technological developments since 2009. We work in the fields of CNC machining, CNC turning, CNC milling, CNC laser cutting, CNC Plasma cutting, CNC punch cutting, and all kinds of machining with our well-trained expert staff.

Request for a quote

SIMGLASS

Turkey

Safety and quality is the number one priority of SİMGLASS®. All SİMsafety® safety glass products are produced by tempering toughen according to architectural demands and by laminating more than one glass panel with composite layers. We produce SİMsafety® safety glass products in sizes up to 2500 mm * 4800 mm and in high quality standards. Heat toughening is part of the work done in SİMGLASS® during the production of tempered glass. Adhering to customer demands, we can produce tempered safety glasses with flat, curved, CNC process.

Request for a quote

SEÇ KAMA

Turkey

We are able to progress in different areas of all types of CNC machining, welding, sheet metal processing, etc.Also offer our partners to produce milling, machining, grinding, casting and welding.Our main products are non-standard and standard machine keys.Sec Kama was certificated by TÜV AUSTRIA Company with ISO 9001: 2015 quality management standard.

Request for a quote

ALUMINYUMBURADA.COM

Turkey

Y axis: 6000mm X axis: 2000mm Z axis: 900mm Get both the material and the cutting service, eliminate your shipping costs. Guarantee both your material and cutting quality. Our 3 Axis CNC cutting machine is capable of vertical cutting.

Request for a quote

HASSAS MAKINA METAL PROCESSING

Turkey

provide laser cutting, plasma cutting, tube laser cutting, optical cutting, press brakes, tube bending, cnc tube processing and guillotine cutting processes within our own facility

Request for a quoteResults for

Cnc processing - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Machines for the manufacture of PVC and Aluminium Doors and Windows (10)

- Cutting - steels and metals (3)

- Milling - steels and metals (2)

- Machine tools - metal machining (2)

- Glass, tempered (2)

- Aluminium and aluminium alloys (1)

- Steels and metals - machining (1)

- Casting, steel (1)

- Forming - steels and metals (1)

- Glass (1)

- Industrial washing facilities (1)

- Injection moulding of rubber and plastic (1)

- Plastics moulding (1)

- Steels and metals - forming and cutting (1)

- Wrought iron (1)