- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinery and equipment

Results for

Machinery and equipment - Import export

NOVELTY STEEL

Turkey

A chemical reactor functions as an enclosed vessel where chemical reactions occur. It's crucial for process designers to ensure the reaction proceeds efficiently toward the desired product, maximizing yield while minimizing costs associated with procurement and operation. Operational expenses encompass factors like energy input and disposal, raw material costs, labor, and other associated charges. Typically, reactants and products within the reactor are in fluid form, either gases or liquids. Continuous reactors maintain a constant operational state, while batch reactors undergo transient operation. Transient operation occurs when a reactor is activated for the first time or following a shutdown, with critical process variables fluctuating over time.

Request for a quote

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quote

NOVELTY STEEL

Turkey

The distinctions among various jig types is related to the methods employed for generating pulsation and the manner in which the heavy fraction is extracted from the jig. The screen’s role is to provide support to the particle bed, and the space beneath it is referred to as the hutch. Typically, the tank is divided into two primary sections: one housing the support screen with the ore bed and another responsible for generating the fluid flow. The heavy discharge from the jig can exit in two ways: either passing through the screen or flowing over the screen. When employing jigging through the screen, every particle in the input is smaller than the screen openings, allowing them to potentially fall through the screen and gather in the hutch. Novelty Structures supplies Mining Jigs for various materials.

Request for a quote

NOVELTY STEEL

Turkey

Various minerals are found in nature either in a dispersed state, where they exist as separate entities, such as native gold particles in silica rock, or in a combined form, where they are bound within a host rock. Dry material separations using screens and sieves are typically attempted down to particle sizes of about 75 microns. Finer materials have a tendency to block the sieve openings. In such cases, screening in the presence of water can be helpful. Separating even finer-sized materials becomes challenging using traditional sieves. For such fine materials, alternative processes like classification need to be employed. Screen Types: * Grizzly Screens * Inclined Vibrating Screens * Horizontal Vibrating Screens * Dewatering Vibrating Screens Novelty Structures supplies various type of Screens for Mineral Processing Plants.

Request for a quote

NOVELTY STEEL

Turkey

Various minerals are found in nature either in a dispersed state, where they exist as separate entities, such as native gold particles in silica rock, or in a combined form, where they are bound within a host rock. Dry material separations using screens and sieves are typically attempted down to particle sizes of about 75 microns. Finer materials have a tendency to block the sieve openings. In such cases, screening in the presence of water can be helpful. Separating even finer-sized materials becomes challenging using traditional sieves. For such fine materials, alternative processes like classification need to be employed. Screen Types: * Grizzly Screens * Inclined Vibrating Screens * Horizontal Vibrating Screens * Dewatering Vibrating Screens Novelty Structures supplies various type of Screens for Mineral Processing Plants.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We offer high quality equipment for roasting nuts and seeds. All equipment complies with international quality standards, and is fabricated using the highest quality materials Our experience and expertise enables us to continuously assess, evaluate and then accommodate for our client’s every need We also offer a reliable after sales service.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We produce equipment for washing, cleaning, peeling, roasting, grinding of sesame seeds. Different lines with different performance. Original traditional technologies for the wonderful taste of the tahini mass. Peeled and roasted sesame seeds are also used for the production of other food products.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Automated line is designed for the production of rectangular marshmallows, cylinders, braids (1-4 colors), etc, using starch by extrusion.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

This line can automatically produce gelatine soft confectionary, (cotton candy), and toffee confectionary The whole line consists of: a sugar melting cooker, convey pump, storage forming machine, air conditioning, and rolling sugar machine. Sanitary construction 1 or 2 colour jelly confectionary (QQ candies) In - line injection, dosing and pre mixing techniques using the proportional addition of liquid colours, flavours and acids Capable of making different shaped confectionary using different moulds Hard confectionary can be produced on the same line by changing moulds A highly automated system producing a quality product whilst reducing production and labour costs Automatic line includes:

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We provide complex services in setting-up of the production line for halva: Consultations on production and engineering issues. Production the equipment of different capacities taking into account technological conditions, set productivity and budget. Innovative heating methods. Organisation of logistics and customs registration. Installation, starting production and training. Training in production technologies of halva using the services of highly skilled and experienced technologists for any time period. Supply of original ingredients. Modernisation of existing enterprises. The universal line is designed to produce an assortment of halva e.g..sunflower, tahini (sesame), peanut, walnut, and can produce halva from shelled and unshelled seeds or kernels. The line consists of main and auxiliary equipment.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Turkish cotton candy pishmaniye is a Turkish sweet made of fine strands by blending flour roasted in butter and sugar. It is sometimes garnished with ground pistachio nuts. Although the texture is similar to cotton candy (candy floss), the cooking methods and ingredients are different. Pismaniye, which is also called floss halva, is a Turkish cotton candy of various types. Halva is pulled into strands using a special method. You may find pismaniye coated with chocolate, topped with pistachio or walnuts and flavoured with vanilla or chocolate. There is also a more buttery version which is called ‘Saray Helvasi’ (Palace Halva). This version isn’t easily pulled apart, so you may prefer this preferable if you find it difficult to eat regular pismaniye. Although cotton candy is a simple dessert with 3 basic ingredients: sugar, butter and flour, making it requires a special talent, so nobody makes it at home. The succulence and flavour of the texture just melts in your mouth.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We produce automated integrated production lines of muesli bar, snack bar, fruit bar, vegetable bar, nut bar, granola bar. The lines include automated groups: supply of ingredients, cooking, forming, cooling, cutting, chocolate coating, decorator, packaging. Depending on the application, we provide automated and semi-automated lines with different performance. Completion with automatic feed systems is possible.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Over the last 10 years our company developed and implemented many technical innovations for the improvement of the product quality and economically effective result of the production keeping to traditional methods of making of Turkish Delight. We provide complex services in setting-up of the production line for Turkish Delight: - Consultations on production and engineering issues; - Production of the equipment of different capacities taking into account technological conditions, set productivity and budget; - Organization of logistics and customs registration; - Installation, start, training; - Training in production technologies of Turkish Delight (Service of highly skilled experienced technologists for any term); - Supply of original ingredients; - Modernization of the existing enterprises.

Request for a quote

BEYAZLI GROUP

Turkey

Concrete Batching Plant - Ready Mix Concrete Plant - Concrete Machinery - Concrete Mixer - Concrete Factory |More Economic | Advanced Technology | More Durable | Fast Delivery| Campaign Price: 170.370 EURO (free installation and free staff training) Contact: seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 100 m³ / Hour ready-mix concrete /8 HOURS Transportation : 5 HQ 40' Containers Concrete Batch Plant Ready Mixing Concrete Plant Concrete Mix Machinery Concrete Transportation | More Economic | Advanced Technology | More Durable | Fast Delivery The ready-mix concrete plant or concrete batching plant is designed with a fully automatic operating system. Designed to work 24 hours. This concrete batching plant system is made to produce ready-mix concrete from the mixture of Aggregate, Cement, Water and Concrete additives with specific ratio. The system of concrete batching plant starts operation with the dosage. Video: https://www.youtube.

Request for a quote

BEYAZLI GROUP

Turkey

Campaign Price: 12.685 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 2250 Concrete Blocks 20 cm width /8 HOURS Transportation : 1 HQ 20' Containers With Single Mortar Hopper - Semi-Automatic or Full Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (With Hopper And Cement Silos) - Daily Capacity 2.500 Hollow Blocks of 20 Cm - 1000 m2 Construction Area - Totally Needs 4 kW Energy - It Is An Ideal Machine That Can Be Able To Produce With Max. 4 Persons - Designed To Work 24 Hours. Through Special Vibro Motors Machine Can Produce Every Stone Which Heigh Between 18 / 25 Cm. Video of machine: https://www.youtube.com/watch?v=VQ_2iQm_C0U&t=5s concrete block machine - Hollow block machine - bricks machine - Cinder block machine - Hollow brick machine - Concrete batching plant Optionally

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEYAZLI GROUP

Turkey

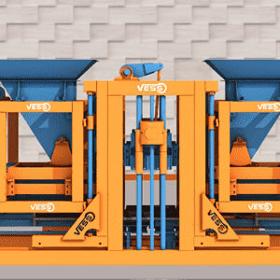

Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 m² Paving Blocks Video:https://www.youtube.com/watch?v=XemT_7bD_tA

Request for a quote

BEYAZLI GROUP

Turkey

PRS 400 SEMI AUTOMATIC MACHINE; Semi Automatic System Is Made Like A Mortar Plant. Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 M² Paving Blocks… Whatsapp Now: +905326382935 see video below https://www.youtube.com/watch?v=uWEj3G78xwA&t=1s

Request for a quote

BEYAZLI GROUP

Turkey

PRS 402 AUTOMATIC MACHINE; Automatic System Is Made Like A Mortar Plant. Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 m² Paving Blocks… WhatsApp Now: +905326382935 https://www.youtube.com/watch?v=64Oq8BixNAk&t=23s

Request for a quote

BEYAZLI GROUP

Turkey

PRS 400 SEMI AUTOMATIC MACHINE; Semi Automatic System Is Made Like A Mortar Plant. Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 M² Paving Blocks Whatsapp now : +905326382935 For more details check our website . Video: https://www.youtube.com/watch?v=S1GluFAdDm0

Request for a quote

TROUVERTOUTICI - MACHINE A PARPAING - FER A BÉTON - PORTE EN BOIS - CENTRALE A BÉTON

Turkey

10.2 AUTOMATIC MACHINE; Machine is designed to work 24 hours. Machine is very fast and has high production capacity through special servo motors. By changing the mould machine can produce any types of Concrete Paving Blocks-Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks which height must be between 2cm and 40 cm. Equipment list with prices, prepared related to the installation layout is given below. Daily capacity (8 hours) 700 m² Paving Blocks / 10.000 Pieces Concrete Hollow Blocks... 10.2 AUTOMATIC MACHINE; The price of the campaign is prepared as complete plant “Turnkey Project”. Except product drying and curing rooms there is no extra equipment needed on the plant area. For a plant of the with these features the recommended installation , curing and stock area is minimum 3.000 m2. There is no obligation for roofing. The prepared concrete floor should be minimum 1/3 of the plant area.

Request for a quote

BESS MACHINE

Turkey

Bess PRS-400 Semi-automatic block making machine can produce 4.000 pieces of concrete hollow blocks (20cm width * 40cm length * 20cm height) or 300 square meters of paving blocks or 1.000 pieces of curbstones. It is just enough to change the mold and the machine can produce 600 different shapes of concrete products. This machine is designed based on European standards and all the parts used in electrical and hydraulic parts are all well-known German brands. Contact us for your own special order and special price. ∙ Daily capacity for concrete hollow blocks: 4000 pieces at 8 hours ∙ Daily capacity for paving blocks: 300 m2 / At 8 hours ∙ Daily capacity for curbstones: 1.000 pieces ( 150 x 700 x 300 ) At 8 hours ∙ Required area for installation: 2.500 m2 ∙ Installation and operator training course: Free ∙ Warranty period: 2 Years

Request for a quote

BESS MACHINE

Turkey

PRS-1000 semi-automatic hollow block machine is the biggest semi-automatic concrete block machine of Bess. This brick making machine can produce 1000 standard hollow blocks or concrete bricks in 8 hours. All Bess hollow block machines are PLC controlled and very reliable with 2 years of guarantee.

Request for a quote

BAYSAL GROUP

Turkey

Concrete blocks machinery Stonymac by Baysal Group Industries a Turkish brand of machinery manufacturer you can order any type of concrete production machinery from us . Manuel , Semi Automatic and full automatic Machines . Production Will take at least 60 days WhatsApp contact number +905424908373

Request for a quoteResults for

Machinery and equipment - Import exportNumber of results

26 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (8)

- Confectionery - machinery and equipment (8)

- Brick-making - machinery and equipment (7)

- Mining and quarrying - machinery and equipment (4)

- Cement-making - machinery and equipment (2)

- Chemical industry - machinery and equipment (1)

- Concrete preparing - machinery and equipment (1)

- Extraction machinery and equipment - minerals and ores (1)

- Mining, surface - machinery and equipment (1)

- Tile-making - machinery and equipment (1)

- Concrete blocks (1)