- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic process

Results for

Automatic process - Import export

AUROMAK MAKINA

Turkey

It is especially used for cleaning, deburring and degreasing of parts that are too small to be placed in baskets. Parts such as fittings, bolts, nuts and nozzles used in the automotive industry; Coating in the coating industry all the small parts before Unions and fittings parts in hydraulic industry, It is used in the cleaning processes of automat on an darmature parts processed on CNC benches in the metal industry.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank . chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electrostainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank . chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor, the washing effect is sprayed on 3 different planes, from bottom to top and from the side with increase.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electro stainless steel body in the alkaline structure at a concentration of 2-5% in the device washing tank. chemical water, each point of the dirty partis specially around contacted by nozzles. While the washing group used rotates around itself with a power fulmotor, the washing effect is sprayed on 3 different planes, from bottom to to pand from the side.

Request for a quote

AUROMAK MAKINA

Turkey

The washing process is done automatically in a completely insulated cabinet, without human touch. During this process, with a pump with an electro stainless steel body in the alkaline structure at a concentration of 2-5 % in the device washing tank chemical water, each point of the dirty part is specially around contacted by nozzles. While the washing group used rotates around itself with a powerful motor,the washing effect is sprayed on 3 different planes, from bottom to topand from the side.

Request for a quote

ESCOM ENHANCED SOLUTIONS

Turkey

Wi-CoRe is an innovative wireless control relay specifically engineered to enable seamless integration between WiT-es and WiPr-es sensors and industrial control systems. It is designed for applications requiring continuous monitoring and real-time temperature and pressure-based adjustments in various industrial settings. Wi-CoRe simplifies temperature and pressure control by receiving data from WiT-es and WiPr-es sensors, processing it, and automatically adjusting relay outputs based on the set parameters, all while displaying the sensor's information on the screen. By intelligently switching its operation according to the temperature and pressure data received from WiT-es and WiPr-es sensors, Wi-CoRe ensures optimal regulation and minimizes manual intervention in control systems. This advanced control relay is the ideal solution for enhancing efficiency and precision in temperature and pressure-dependent industrial processes.

Request for a quote

ESCOM ENHANCED SOLUTIONS

Turkey

Wi-CoRe is an innovative wireless control relay specifically engineered to enable seamless integration between WiT-es and WiPr-es sensors and industrial control systems. It is designed for applications requiring continuous monitoring and real-time temperature and pressure-based adjustments in various industrial settings. Wi-CoRe simplifies temperature and pressure control by receiving data from WiT-es and WiPr-es sensors, processing it, and automatically adjusting relay outputs based on the set parameters, all while displaying the sensor's information on the screen.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin Production Machine is an industrial level machine designed for mass production of napkins. Modern napkin manufacturing machines meet high standards in terms of both quality and efficiency and have a wide range of uses. Napkin Production Machine is an industrial machine used to produce napkins from raw paper material. This machine automatically performs the processes of cutting, folding and sometimes printing the paper. The main purpose of the machine is to meet the demand by producing napkins at high speed and continuously. Fast Production Capacity: Continuous and fast napkin production. Multifunctional Operations: Ability to perform operations such as cutting, folding and printing together. Flexible Production Options: Ability to produce napkins in different sizes and patterns. User Friendly Interface: Easy operation and adjustable functions. Napkin Production Machine is used in places such as napkin producing factories and paper processing plants.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

Tu rquoise CTcP is designed for use in both automatic plate processors and manual processing. It contains water soluble organic substances. It can work with all diazo-based plates currently on the market. Because of it is produced in high concentrated form, it is also very economical, easy transport and cost saving produc t. PROPERTIES Sharpen images,less dot gain Diluted 1+9 so it is cost saving Does not contains non water soluble substances Perform withall kindof positive plateswithout any problem VOC free product It doesn’t cause residues and calcium acumulation insidethe container it doesn’t freeze until -4C temperature APPLICATION Add 9 litres water in 1litre Turquoise 1+9 torautomatic processors and manual use. For some plates you may need to dilute more than our recommendation, please test it before you use for regular processing.

Request for a quote

NOVOSIM

Turkey

Development of rotating components require intensive testing. While the main goal may be reaching durability and life targets,noise , vibration, temperature and other parameters may play an important role for the customer expectations. Therefore, Novosim offers a customizable testing dynamometer which may be used to in the product development of passenger, commercial, heavy duty or even military vehicle components. Software is easy to use and also highly customizable allowing different product lines to be tested under a single system. With the help of regenerative braking, electricity is recovered and loops back to the test system providing efficient operation. Assuming the tests may run about 1 month, the consumption can be an important parameter for cost control. Different types of data can be collected and stored in a database for further comparisons and tracking of the development process. System automatically generates a report which is also customizable.

Request for a quote

KEDY

Turkey

Manual All controls are made by the operator via the control button. Each crane is controlled by an operator. Semiautomatic H Busbars are an automatic transport system from the unloading area to the loading area. The system is suitable for automatic operation. Transitions between stations are made by operator control. Waiting and immersion times are automatic in the boilers. Automatic operation when necessary, but in case of failure, intervention with external operators, transitions between boilers are made by the operator. Fully Automatic The whole process is controlled from the skada screen. There is no need for an operator at the beginning of the cranes. All boiler chemical controls are made automatically from the skada screen. Transitions between stations are made automatically to unloading stations. It has the possibility of easy maintenance and intervention with remote access. Lifting drive is with chain gear system and it is supported by rollers on the guide rail

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION After welding clean up down and corner sides of 90º PVC Profiles after welding. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Stripping blade levels are adjustable according to laminated and un laminated profiles Pneumatic tool fixing and releasing system Single or multi cleaning operations can be processed Automatic start up feature when profile placed on the table Stops automatically after stripping and cleaning operation STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200 Wx3 400V AC 50~60 Hz 3000 D/dak RPM D: 215 d: 32 mm. 36 Lt/dak. 6~8 Bar 92x 101x 143 cm 249 kg. 198 kg.

Request for a quote

ASELPLAST AMBALAJ VE TEKS.ÜRÜN.SAN.

Turkey

The machine type stretch film protects products from external factors such as hot, cold, rain, dust and dirt. The outer surface of the stretch film is glossy and slippery. Therefore, it doesn’t catch dust and dirt. It prevents the pallets sticking to each other. It is transparent, light and economical. It is also resistant to all weather conditions. It can be used in all kinds of products. As a consequence of the flexibility; it isn't affected by pointed and sharp corners and it doesn't need rope or needles, it is safe and economical in the packaging of bottled products. Features It is used in packaging process that is automatically done by machine The width is 50 cm Roll wrapping length is min. 750 mt, max 1500 mt. The thicknesses are 17-23-25 microns

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

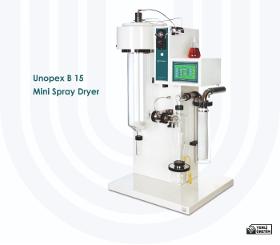

UNOPEX

Turkey

Unopex offers the perfect solution for first trial spray dry processing, feasibility studies, process development and product researches. Unopex B 15 Mini Spray Dryer is a laboratory equipment for quick and gentle drying of products from water or organic solvent based feeds. ● Laboratory scale reproducible powder production ● Quick and easy operation ● Fast installation, simple assembling and easy cleaning ● Touchscreen operating panel ● Display and easy setting of the process parameters ● Automatic nozzle cleaning ● CE compliant

Request for a quote

HPM HIJYEN PROSES MAKINALARI

Turkey

HGX-103 provides brushing for shoe sole, hand washing, hand drying and hand disinfection processes . It is designed to be highly reliable rigid-robust. In general, it is produced with double-hand disinfectant turnstile access control, automatic sensor liquid soap dispenser, process monitoring with PLC system, stainless steel disinfectant sprayer nozzles, adjustable height, anti-scratch plastic feet, brush and hygienic mat in the chemical pool for boots, and all in stainless steel material.

Request for a quoteResults for

Automatic process - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Industrial washing facilities (9)

- Bottling and filling - machinery and equipment (1)

- Testing equipment (1)

- Axles, vehicle (1)

- Buckets and grabs, crane (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Electricity - import-export (1)

- Electronics - import-export (1)

- Engine testing and regulating equipment - electronic (1)

- Foods, health (1)

- Napkins, paper (1)

- Varnishes (1)