- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding systems

Results for

Welding systems - Import export

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Bag Cement Silo, also referred to as a Cement Bag System, is an entirely different concept for storing cement compared to the conventional bulk storage systems using welded silos. In these types of systems, the cement is stored in very huge containers, making the system ideal for projects benefiting from the convenience and flexibility of bagged cement. Those bags are filled by mass at a production or distribution center with a specified mass of cement. Once filled, they are hoisted into place on construction sites, ready-mix concrete plants, and facilities, where they can be stored and discharged as necessary.The flexibility of Bag Cement Silos makes them an ideal choice for small-sized projects or sites with space restrictions. Because each bag is essentially a pre-sealed package, the chances of contaminants entering or spoiling the material are significantly diminished.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Bag Cement Silo, also referred to as a Cement Bag System, is an entirely different concept for storing cement compared to the conventional bulk storage systems using welded silos. In these types of systems, the cement is stored in very huge containers, making the system ideal for projects benefiting from the convenience and flexibility of bagged cement. Those bags are filled by mass at a production or distribution center with a specified mass of cement. Once filled, they are hoisted into place on construction sites, ready-mix concrete plants, and facilities, where they can be stored and discharged as necessary. The flexibility of Bag Cement Silos makes them an ideal choice for small-sized projects or sites with space restrictions. Because each bag is essentially a pre-sealed package, the chances of contaminants entering or spoiling the material are significantly diminished.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Turn Table, precisely provide to welding by turning clockwise or counterclockwise of parts connected to it horizontally. It also enable movement in the rotation axis. . The work table is operated with a T-slot turntable to ensure that the workpieces are fully fixed to the work table. It is designed with the aim of increasing efficiency, eliminating the need for welding in difficult positions and considering ergonomics of employees.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

-Dust protected strong mechanical structure -Feature of positioning welding head on 1,2 or 3 lines -Feature of oscillation on 1, 2 or 3 lines -Enable to work on different axis without mechanical adjustment -Enable to be used in Submerged,Inert gas or TIG -Enable to integrated with automations systems -“OLED” screen which all the parameters can be seen.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

EKO circular welding systems are designed for circular pieces’ integration with various welding methods in different positions. It appeals to a wide usage area in which all of the welding techs single and multipass welding tig, mig/mag and submerged welds can be used. It is used in environmental and linear welding of materials like circular formed, boiler, thermosiphon, hydraulic cylinder, conveyor roller, conveyor wheel, solar power boilers etc. It increases output and gain with the savings of materials and time. Upon request, production is made on different diameter, height and features

Request for a quote

KAYGUN STEEL METAL IND. TRADE CO. LTD.

Turkey

Industrial welded wires: Galvanized or black iron point welded grid wire system.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

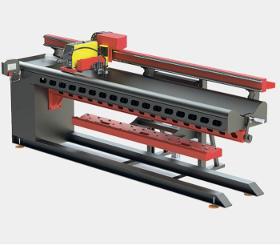

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Access to the workpiece from the outer surface Installation close to the wall edge Linear welding with walking motion Circular welding on the rotating system Motion transfer with linear slides and trolleys Ability to connect welding machine, oxygen and plasma cutting unit Ability to create special applications and stations

Request for a quoteResults for

Welding systems - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (6)

- Electron beam welding - equipment (2)

- Welding, electric - equipment and supplies (1)

- Autogenous welding machines (1)

- Steels and metals - welding and brazing (1)

- Active electronic components (1)

- Concrete preparing - machinery and equipment (1)

- Fences (1)

- Fibre-cement - products (1)