- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- units

Results for

Units - Import export

BRN SLEEP PRODUCTS

Turkey

BRN Sleep Products LLC with its 300,000 SQF factory is located in Orangeburg, South Carolina. Our Orangeburg facilities have made it easier for us to deliver our Made in USA products in a convenient and expedited way to all our customers. This has allowed us to become one of the largest and most trusted suppliers to many online retailers' customers and other US stores. We provide great advantages to the customers by selling directly from the manufacturer to the stores. This is a great opportunity for our customers. We are excited about the opportunity to sharing the experience and knowledge we have gained in the production of mattress and sleep products with our customers. In our endeavor to train entry-level employees integrated to our mission in the USA, we have received an outpouring of support from the United States and local governments. We are masters in the ability to roll and pack an array of mattresses, such as foam mattresses, Bonnell, and pocket spring(hybrid) mattresses.

Request for a quote

ATMOSFER MACHINERY

Turkey

Introducing the Diamond Series Fresh Water Maker, a state-of-the-art reverse osmosis system designed for marine applications. This system offers a nominal production capacity ranging from 40 to 80 cubic meters per day, ideal for use with seawater at a temperature of 25°C and a salinity level of 35,000 parts per million. Housed within a durable stainless steel rack, this system is skid-mounted for easy installation and comes equipped with an integrated PLC control and starting cabinet for user-friendly operation. One of its standout features is the automatic freshwater flushing system, which serves as a safeguard for the membranes, prolonging their lifespan. Additionally, it boasts an automatic "water drop" system with a high salinity alarm, ensuring the quality of the produced water. To enhance performance monitoring, the unit is fitted with a digital flow-meter, providing precise readings of both momentary and cumulative water production.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

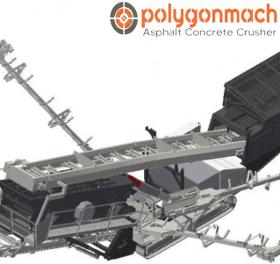

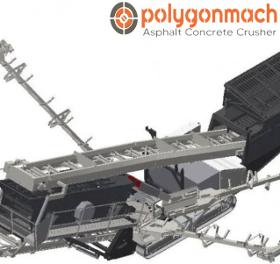

Our mobile track plants as below Track Mounted Screen Plant Track Mounted Jaw Crushers Track Mounted Impact Crusher Track Mounted Cone Crusher Track Mounted Scalper Screens Track Mounted Stackers Track Mounted VSI Crusher

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

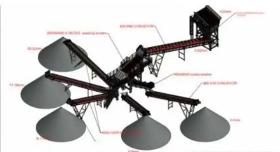

A Mobile Wheeled Crushing Screening Plant is a versatile and mobile plant used in various industries for crushing, screening, and sorting operations. This type of plant is mounted on wheels for easy transportation between various job sites and, therefore, allows for efficient on-site processing of materials. A mobile, wheeled processing plant performs the main function of transforming stones, minerals, or construction waste into given dimensions according to the need and separating and screening processed material with respect to given specifications. These are high-turnover, critical plants in the construction, mining, and recycling industries, in which flexibility and mobility are important for maximizing operational efficiency and reducing transportation costs. The common mobile wheeled crushing screening plant mainly includes a primary crusher for an initial crush, secondary crushers for processing further, and screens to separate the crushed material into various sizes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Mobile Jaw and Cone Crusher 1-PMCC1 can be classified into the category of mobile crushing and screen equipment. It has the potential to process an extensive variety of materials by combining jaw and cone crushing. This unit usually is equipped with a jaw crusher acting as primary crusher equipment, which can break stones or minerals to small pieces, making them easy to handle. The cone crusher allows for secondary or tertiary crushing, creating high and homogeneous final output, which are further processed or used as end products. Typically, most PMCC1 models are fitted with such advanced features, giving them adjustable settings to control the size of the output material to be produced, hence flexibility in meeting all other project requirements. PMCC1 will be provided with a combination of both jaw and cone crushers that will offer an integrative solution for mining, construction, quarrying, and other industries of a like nature in processing different materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Limestone is effectively a sedimentary rock primarily consisting of calcium carbonate, typically in the form of the mineral calcite. Over vast ages, this rock builds up from depositional formation of marine creatures such as shellfish, coral, and algae that accumulate, sowing up as solid rock. Much of the time, these rocks contain fossils. Moreover, visible formation in terms of layers further bears record to its formation from the ocean's bed. Limestone has been used in construction since time immemorial owing to its high content of calcium. It is greatly durable, relatively easy to cut and carve, and provides an aesthetically pleasing material fit for building purposes of every type, from monuments to pavement stones. Adapted in highly ornate designs and sculptures, it is smooth in texture and beautiful in its coloration, thus giving a soft but timeless material for the architect or the builder.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Granite stone is a very popular, hard, igneous rock with wide attractiveness and use. Produced from the slow crystallization of molten rock below the surface of the planet, granite is usually made up of quartz, feldspar, and mica. These very minerals are responsible for the speckled look and wide color range, making it a favorite for many residential and commercial projects. This robust nature of the stone makes it associated with features such as scratch resistance, stain resistance, and heat resistance that number in many applications on countertops, flooring, and other components that involve decoration. On the other side, granite is applied outdoors with such applications as paving stones, cladding, and different landscaping features due to its strength and resilience against changes brought by weathering and wear.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

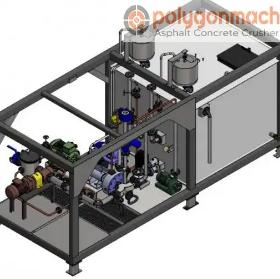

A containerised bitumen tank is a portable storage unit designed to transport, store, and heat bitumen. The bitumen, being a heavy viscous liquid or semi-solid derived from crude oil, has extensive application in road construction, roofing, and waterproofing projects. They are all self-contained within a standard shipping container, thus highly portable and ideal for projects of a mobile nature. Advanced insulation and heating systems ensure that the bitumen is kept within the temperature range so that it will always be ready for immediate use at any job site. The major advantage of containerised bitumen tanks is that they are portable. Because they are enclosed in standard containers for shipment, it makes them a very valuable asset for mobile bitumen storage and heating requirements. Whether in the process of road construction or large industrial applications, these containers create an easy way to preserve bitumen in a workable state so that whenever needs arise

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A horizontal bitumen tank is a specially designed storage unit to accommodate the safe and efficient storage of bitumen, a thick sticky substance produced from crude oil. Such containers are of key importance in industries such as road construction and waterproofing or roofing, among other industrial procedures where bitumen is a major material. They normally feature in asphalt plants and bitumen treating facilities as storage reservoirs for the bitumen to be used in several works. Design for horizontal bitumen tanks is specially tailored to manage the unique properties of bitumen. It is designed to be quite difficult to handle at low temperatures because of its high viscosity. These are fitted with systems to keep the bitumen at the right temperature, ensuring it stays within an easy workable state for transportation and easy use. It offers a controlled environment of storing bitumen to ensure that the material is always ready for construction and industrial usages.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

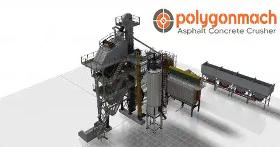

The MCA 100-120 tph Continuous Asphalt Plant is the technology pioneer in asphalt production, offering best-in-class efficiency and performance for medium to high-volume projects. This continuous asphalt plant is durable and fully equipped with advanced characteristics that enable quality continuous asphalt mixture production. It offers a range of production capacities from 100 to 120 tons per hour, which deals with a wide variety of road construction applications. This plant is designed for the production of asphalt for any requirements with the ultimate accuracy and consistency of results. The power-packed MCA 100-120 tph plant, standing out to be the strongest of its kind in construction and ultra-modern technology, is suitable for all projects from highways to luxuriant urban roads and on to industrial zones. It can produce numerous sorts of asphalt mixtures, including those needed for base, binder, and surface courses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is the Continuous Type Asphalt Plants Capacity? An inventive solution for continuous asphalt production is presented by Polygonmach with the MCA 40-60 Tph Continuous Type Asphalt Plant. A full and in-depth explanation is provided here: Overview of the Product Envisioned to cater to small- to medium-sized projects Polygonmachs 40-60 TPH continuous type asphalt plant marks a noteworthy advancement in asphalt production technology. This plant efficiently produces high-quality asphalt mix by combining cutting-edge machinery and engineering. With a 40 to 60 tons per hour capacity it is notable for its productivity in a small package. Its modular design facilitates simple assembly and breakdown guaranteeing seamless transportation between locations. For construction companies that operate in several locations this makes it a priceless asset.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

How much capacity does a hot mix mobile asphalt plant have? With its unique combination of exceptional efficiency flexibility and asphalt mix quality Polygonmachs 100-120 TPH mobile asphalt plant raises the bar for mobile asphalt production. This high-capacity plant offers unparalleled mobility and great performance making it ideal for medium- to large-scale projects. It is the best choice for a range of building needs and works well for tasks requiring the rapid production of high-quality asphalt. With a production capacity ranging from 100 to 120 tons per hour this mobile plant ensures that even the strictest asphalt needs are met. With its state-of-the-art technology and durable design the plant is a unique choice for high-demand scenarios guaranteeing consistent quality across a range of project environments be it a large highway project or significant infrastructure development.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Capacity of a Mobile Asphalt Plant Extremely mobile and performance-driven the Polygonmach 40–60 TPH mobile asphalt plant is built to last. Offering both efficiency and flexibility this plant with a 40–60 tons per hour capacity is perfect for small to medium-sized projects. Due to its small size which makes it simple to transport and set up at different job sites it is the best choice for remote or temporary locations where space and logistics are limited. Because efficiency was the primary design consideration this plant is simple to operate and provides consistent asphalt quality. Operators can easily manage production thanks to the user-friendly control system which maximizes asphalt mix quality and output. A mobile asphalt plant with a capacity of 40–60 TPH can be used for a variety of tasks including both new highway construction and road repairs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PBA 200-240 TPH Stationary Asphalt Plant from Polygonmach will help you enter the future of efficient asphalt production With unparalleled efficiency and quality for massive construction projects Polygonmachs PBA 200-240 TPH Stationary Asphalt Plant is built to transform the asphalt production process. Modern machinery guarantees peak performance which makes it a priceless tool for projects needing large amounts of asphalt. The PBA 200-240 TPH Stationary Asphalt Plant is unique in the industry and we will show you why by delving into its functions parts assembly method and special advantages. The PBA 200-240 TPH Stationary Asphalt Plant: What is it? Large-scale construction projects require asphalt of the highest caliber which is why the PBA 200-240 TPH Stationary Asphalt Plant has a high capacity. This plant which can produce between 200 and 240 tons per hour guarantees dependable efficient operation which is essential for maintaining the momentum of large-scale projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With the Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant discover the world of efficient asphalt production Because of Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant asphalt produced for large-scale construction projects will be produced differently. These cutting-edge instruments can optimize the asphalt production process which makes them an invaluable asset for large-scale construction projects. The PBA 120–140 TPH Stationary Asphalt Plant is covered in great detail in this article along with information on its assembly process and special features. What is the PBA 120-140 TPH Stationary Asphalt Plant like? We guarantee its dependable and effective operation. Because exact control is maintained throughout the entire production process every batch of asphalt produced by this plant is guaranteed to meet the highest industry standards.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Polygonmachs 60-80 TPH Stationary Asphalt Plant is Revolutionizing the Construction Industry The 60–80 TPH Stationary Asphalt Plant from Polygonmach is revolutionizing the construction sector. In addition to providing outstanding quality this cutting-edge technology promises effective operation and a step toward sustainability. Your projects will benefit from your investment in the future of asphalt production by incorporating this state-of-the-art plant. Picture a building site where the asphalt is produced with unparalleled dependability and accuracy. With a focus on efficiency and waste reduction Polygonmachs stationary asphalt plant guarantees that each batch satisfies meticulous standards. This is a paradigm shift in the way we approach construction not just an upgrade making every project more efficient and eco-friendly. Extraordinary Caliber for Unparalleled Efficacy Quality is crucial when producing asphalt.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Bag Cement Silo, also referred to as a Cement Bag System, is an entirely different concept for storing cement compared to the conventional bulk storage systems using welded silos. In these types of systems, the cement is stored in very huge containers, making the system ideal for projects benefiting from the convenience and flexibility of bagged cement. Those bags are filled by mass at a production or distribution center with a specified mass of cement. Once filled, they are hoisted into place on construction sites, ready-mix concrete plants, and facilities, where they can be stored and discharged as necessary. The flexibility of Bag Cement Silos makes them an ideal choice for small-sized projects or sites with space restrictions. Because each bag is essentially a pre-sealed package, the chances of contaminants entering or spoiling the material are significantly diminished.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Compact Sand Washing Plants are small, specifically designed plants developed for the effective cleaning and separation of sand particles in industrial applications. Most of the plants consist of a combination of equipment, including a sand washer, dewatering screen, hydrocyclones, and fine material washers, all integrated into one compact and mobile unit. Compact Sand Washing Plants are mainly designed to remove impurities, silt, and contaminants from sand to leave the final product clean, well-graded, and fit for use in construction, concrete production, and other industrial procedures. These plants integrate several washing and screening mechanisms in an integrated compact design, ensuring high effectiveness in washing and dewatering sand while guaranteeing better output quality at space and operationally lower footprints.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Fine material washers, otherwise known as spiral classificators or screw washers, are typically utilized in the aggregate and mining industries to clean fine materials such as sand, gravel, or even crushed stone. This machine contains a rotating screw shaft enclosed in a trough that conveys a water/material mixture. While the materials are being moved along the screw shaft, the agitating and rotating action of the screw enables the washing and separation of the finer particles from the coarser ones. Water is introduced at the same time into the system to aid washing for the removal of impurities, then leaving fine, drier materials that are ready for further processing or stockpiling. Fine material washers are used to process fine materials into high-quality and pure materials that can be applied in construction and in the production of concrete, among other uses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The log washer is a unique, heavy machinery equipment used in mining, aggregate processing, and mineral processing to clean and scrub ores, rocks, and minerals. This machine comprises an enormous shaft shaped like a log with paddles or blades which turn and shake the material in a container that can be filled with water or washing solution. The log washer paddles turn to generate a scrubbing action, thus driving their fruit, while lubricating forces remove the contaminants in the form of clay, silt, and other impurities. Supported by an aggressive action, the log washer acts to break down and remove unwanted materials while delivering a cleaner and more refined product. These particular applications have proven to work quite well with log washers, taking into consideration material preparation for further processing or to meet required quality specifications that call for thorough cleaning and scrubbing.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Buildings made expressly to hold bulk cement or other powdered materials like sand fly ash slag or lime are known as cement silos. Construction sites concrete batching plants and other industrial settings that require large quantities of cement to be readily accessible for production processes are frequent users of these cylindrical silos. Small portable silos with wheels for short-term use and large stationary silos capable of holding substantial volumes of cement are just two examples of the different sizes and configurations of cement silos. Steel or other sturdy materials that can support the weight of the material being stored and shield it from contaminants moisture and other elements that can lower its quality are usually used to make them. A cement silos main purpose is to hold and safeguard bulk cement until its required for usage in different construction projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A concrete production facility is a dry type where no water takes part in the mixing. In this type, water is not used for casting the mix. At this point in time, unlike the traditional concrete batching plants allowing the water to mix the materials, dry-type plants include mixing components like cement, aggregates, and admixtures without water in the mix. This type of batching plant is specially designed for the production of mixes by mixing all dry components and subsequently adding water in the final stages of the mixing cycle. Conditions under which concrete batching plants would be preferred include: nature of job, scarcity of water, restriction of water by local authority for environmental reasons, and transportation and storage difficulties in wet materials. In this sense, the installation of dry mixes along with a water metering system brings the most sustainable and efficient way of the concrete production process.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A compact batching plant or mini batching plant is a smaller version of the conventional concrete batching plant made for projects having space and/or smaller concrete production requirements. Normally the setting is mobile with a tiny footprint, which is ideal for urban applications, renovation projects, or small construction sites where space is a major issue. The compact batching plants, ideally designed for portability, incorporate four aggregate bins, specially configured cement silos, a single shaft mixer, and a control system for suitable and accurate batching and homogenous mixing of concrete on the project site. Its compact design further allows easy transfer across sites and quick installation, thereby ensuring flexibility and convenience in concrete production for any particular construction application.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Apron Feeder: An Integral Component in Bulk Material Handling An apron feeder is a crane, hardwearing, specialized bulk material handling machine found in the industries mentioned above. Apron feeders contain series of overlapping heavy steel pans or plates that are mounted upon high-powered chains. The chains pull the material along the feeder, therefore conveying the material from one point to the other. Apron Feeders are designed for a wide variety of materials, from large rocks down to ores and other very abrasive materials that may prove problematic for other feeder types. The difference in an apron feeder from the other types of feeders can be seen in its well-built design and the capability to endure heavy impact, besides intense abrasion, typically experienced in heavy industrial applications. They run at a regulated speed, delivering a constant flow of material to the downstream process equipment such as crushers

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Wobbler Feeder is a very important feeder and pre-screening equipment in the mining and aggregate industries, especially prior to the primary crusher. A Wobbler Feeder differs from conventional feeders in that it is capable of handling wet, sticky, or clay-bound materials through an innovative system of elliptical bars mounted on eccentric shafts. These bars rotate and wobble to produce mild agitation, keeping the flow under control. The effect helps to loosen lumpy material and break sticky material into smaller lumps to ensure free movement of material in the process plant without obstructions or delays. Probably the most important feature of a Wobbler Feeder is its capability of processing material, which, for other types of feeders, is considered being of considerable handicap.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Automatic Distribution Conveyor – Shuttle Type: An Invitation The Automatic Distribution Conveyor possessing a Shuttle Type design is a sophisticated material handling system applied in warehouses, distribution centers, and manufacturing facilities. This equipment is primarily engineered to automate the sorting and distribution of items along a conveyor line. Unlike the other systems, this system has a shuttle mechanism that runs across the entire width of the main conveyor, picking items up and transferring them transversely to specific offloading locations. It operates independently of the main conveyor and can handle the accurate transferring of items depending on their destination, size, weight, or any other parameter that needs to be considered. Incorporate this shuttle mechanism to improve the total efficiency and accuracy of the system in handling materials and automate the flow of goods through various processes from processing to shipping.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Track Mounted Impact Crusher Because of its unmatched efficiency and performance our track-mounted impact crusher stands out in the market. Precisely engineered it is intended to take on the most difficult jobs and deliver reliable superior outcomes. With its cutting-edge technology our crusher operates at peak efficiency reducing downtime and increasing output. Our impact crusher provides the strength and performance required to complete the task quickly and effectively regardless of the size of the project. A Systematic Approach At the heart of our design philosophy is ease of use and maintenance. Our track-mounted impact crusher has easy-to-access parts and intuitive controls because it was designed with the operator in mind. By lowering the chance of operational errors and cutting down on training time this user-friendly method guarantees a productive workflow.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Track Mounted Mobile Washing and Screening System? Track-mounted mobile screening and washing units are adaptable and productive pieces of machinery used in recycling mining and aggregate production. A vast variety of materials including aggregates ores coal and industrial minerals can be screened cleaned dewatered and classified using these units. The mobility of track-mounted mobile screening and washing units is a significant benefit as it facilitates their easy transportation to various job sites. This adaptability lowers the need for multiple machines at different locations while increasing productivity. Furthermore these units are outfitted with cutting-edge features like hydrocyclones vibrating screens and water treatment systems to guarantee peak performance and superior quality of the finished product.

Request for a quoteResults for

Units - Import exportNumber of results

138 ProductsCompany type

Category

- Concrete preparing - machinery and equipment (68)

- Unit heaters (16)

- Glass, insulating (13)

- Electricity generators (7)

- Electricity generation (4)

- Greenhouses and glazing units (1)

- Furniture for Hi-Fi and stereo systems, video and television (1)

- Hydraulics systems (1)

- Concrete mixers (1)

- Glass (1)

- Cabinets, bathroom (1)

- Hotels, bars, cafés and restaurants - machinery and equipment (1)