- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- touch panel

Results for

Touch panel - Import export

GRIFT MAKINA

Turkey

Powder products packaging machine. The price changes according to the desired sensitivity and weight. Flour,powder coating,,salep,coffee v.b filling machine for powder groups Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is designed for companies that are just starting out and have low production capacity. It is quite simple and precise to use. As a type of bag, it is suitable for use for ready-made bags. It has automatic feeding and can do fast and precise weighing on ready-made bags. Pieces may vary by minutes upon request and request. A controllable servo motor is available for a fast and precise filling. The desired product weight is obtained by the number of turns of the filling screw. The size and dimensions of the screw may vary depending on the type of product and the desired filling amount. The mixer system located inside the chamber prevents the product from jamming.

Request for a quote

GRIFT MAKINA

Turkey

It works with the pneumatic system. Ability to make precise filling with manual 1% accuracy of weight adjustment We are able to manufacture STANDARD production machines between 0-5000 KG. Dec. We are able to manufacture special production machines between 5000-25000 Dec. We have the possibility of customer-specific design. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is suitable for precise and fast packaging of granular products. Control is provided by a separate processor independent of the machine. Control is provided by a separate touch screen independent of the machine. It provides possibilities such as automatic cleaning, automatic product feeding and different language options. It is manufactured with different sizes, types, speeds and different number of pads. Compared to these, the shrouds are easy to disassemble and easy to clean.

Request for a quote

GRIFT MAKINA

Turkey

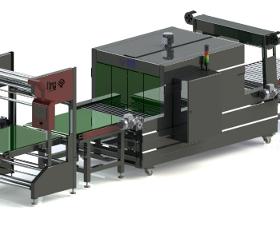

We have the production of machines in the desired sizes and dimensions. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. There are special production machines in our production. It is designed to pack your desired size products in a precise and fast way. Design and production are carried out according to the desired product type and specifications. It is suitable for products that do not melt with an instant temperature of 200 degrees in the tunnel. It has a sensitive and fast retention feature with SSR switching system. The supply voltage is 380 V/ 50 Hz.

Request for a quote

GRIFT MAKINA

Turkey

It works with the pneumatic system. Ability to make precise filling with manual 1% accuracy of weight adjustment We are able to manufacture STANDARD production machines between 0-5000 KG. Dec. We are able to manufacture special production machines between 5000-25000 Dec. We have the possibility of customer-specific design. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is suitable for precise and fast packaging of granular products. Control is provided by a separate processor independent of the machine. Control is provided by a separate touch screen independent of the machine. It provides possibilities such as automatic cleaning, automatic product feeding and different language options. It is manufactured with different sizes, types, speeds and different number of pads. Compared to these, the shrouds are easy to disassemble and easy to clean.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce high quality of interlocks, blocks,curbstones and other concrete products as requested by the customer. One press can produce 42pcs of interlocks or 18 pcs from blocks 20x40x20cm block and curbstones. The machine can be used with a stacking system or without stacking system. The press time is 20-24 seconds. It has two working system, it can work either full automatic or semi automatic depending on user preference. Movements on the system will be controlled by a PLC. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood. There are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KUPA MOVABLE GLASS SYSTEMS

Turkey

• New design featured easily cleanable panels • The ability to easily control the movement of panels with a remote control • The feature of being an opening vasistas on the bottom panel and a self hinged gradual opening • Automatically seperating panels without touching in the middle and top panels • System allows you to create open or closed spaces without occupying extra space and allows effective ventilation without a security risk • Strong chains of moving system ensures highest security and long years durability with minimal maintenance • Panel profiles that allow using single or double glass • Interlocking structure of panel profiles and insulation brushes that are used in all sides of the system ensure highest insulation • Robust profile structure, 3 panel design and interlocking between the panels, allow highest wind resistance and security • Aesthetic caps of track profile and elegant design of track and panel profiles, allow maximum transparency

Request for a quoteResults for

Touch panel - Import exportNumber of results

7 ProductsCountries

Company type