- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- products for plants

Results for

Products for plants - Import export

ROBINSON CO.

Turkey

The control sieve is used for the final control before packaging in the packaging unit of the flour factories. The product arriving at each passage of the square screen enters through the pressure pipe and moves vertically and horizontally through the pre-set flow paths along the passage. The final checks are made after the flour sifting process. The flour, whose last checks are made, is directed to the bagging process. Apart from flour and semolina factories, it is used in processing plants of wheat, corn and similar grains, in feed mills, in various food products processing plants for the final screening of mixed feeds and for the sifting of large-grain corn, crushed pellet feed, barley, oats and similar processes. Application Fields ◾ At flour mills: For wheat, corn and similar grain processing plants ◾ At feed mills: For final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processe

Request for a quote

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ATMOSFER MACHINERY

Turkey

The smart production line for Diesel refers to an advanced manufacturing system that utilizes automation, digital technologies, and data analytics to optimize DEF’s production process, such as AdBlue®. DEF is a solution used in selective catalytic reduction (SCR) systems in diesel engines to reduce harmful nitrogen oxide (NOx) emissions.

Request for a quote

ATMOSFER MACHINERY

Turkey

The smart production line for UAN 32 refers to an advanced manufacturing system that incorporates automation, digital technologies, and data analytics to optimize the production process of UAN 32 fertilizer. UAN 32 stands for Urea-Ammonium Nitrate solution with a nitrogen content of 32%.

Request for a quote

ATMOSFER MACHINERY

Turkey

We are proud to present our state-of-the-art multifunctional production plant, a groundbreaking innovation designed to streamline and simplify the process of manufacturing various solutions, including liquid fertilizers such as NPK, UAN, and more, as well as AUS solutions like AdBlue. This fully automatic and smart production plant is set to revolutionize the industry of liquid fertilizer.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

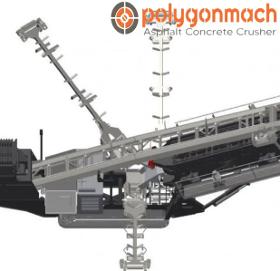

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 40-60 tph granite crushing and screening plant is an intermediate-sized facility, compact yet potent, designed to deal with small to medium-sized operations where granite is crushed and screened into such products. These plants can be configured either as mobile or fixed installations based on project demand. Plants primarily produce high-quality aggregates from granite stones, which are major material used in constructions, infrastructure development, and other industrial applications. These are best suited for works whose requirements fall within the moderate output of crushed granite at a time between 40 to 60 tons per hour, assuring effectiveness and reliable service.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 50-100 tph gabbro crushing and screening plant is designed to handle the toughest and densest of all igneous rocks, Gabbro, producing various aggregate sizes. This is of capacity 50 to 100 tons per hour, so it would service medium to large-scale production. This plant primarily functions as a facility for crushing large stones of gabbro into smaller ones and then sorting them out according to the size requirements. Crushing normally starts with a jaw crusher, which does a primary size reduction. Following this are the secondary and tertiary crushers, which give the product different aggregate sizes. The crushed gabbro is then screened into fractions by screening equipment to ensure that the final product meets the requirements that are required in construction and other industries. This plant has the capacity to process 50-100 TPH, making it versatile and efficient in producing high-quality gabbro aggregates.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Introducing Our Advanced Track Mounted Screen Plant Our advanced track mounted screen plant is designed to deliver exceptional performance in various screening applications. Featuring three triple screen decks with a screen size of 5,200 x 1,870 mm, it ensures optimal material separation and high productivity. The plant weighs 36,500 kg, reflecting its robust construction. Driven by a hybrid system with motors from Perkins, Cummins, or Volvo, it offers the flexibility of operating on electricity or diesel. The screen angle is adjustable between 12-18 degrees, allowing for versatile screening tasks tailored to different materials and project requirements. High-Performance Triple Screen Decks The triple screen decks of our track mounted screen plant provide superior screening capabilities, handling large volumes of material with ease. Each deck is meticulously designed to ensure efficient and accurate separation, enhancing overall productivity.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Bitumen Tank? A bitumen tank is a place where bituminous or asphalt binder is kept as a product in liquefied form. Basically, the name bitumen tank applies to any bitumen storage tank. Its main function is to store bitumen, and it is a very useful equipment for both the road construction and building industries. They guarantee established bitumen-keeping temperatures and prevent the product from hardening. Normally insulated and heated, bitumen tanks store the material under ideal conditions, ensuring its availability when combined with the aggregates in the production of asphalt mixes. The size of the tanks used depends on the requirements of the operation. When making such asphalt, larger tanks are found in asphalt production plants so that a continuous supply of bitumen is assured to the operations. The bitumen tanks are an important part of the bitumen production plants, road construction projects, and all operations included in paving processes.

Request for a quote

UMMANMAK

Turkey

Asphalt plants create the hot mix material by mixing different types of aggregate, bitumen and filler. The advantage of our continuous type asphalt plants is production high quality asphalt, because of very sensitive dosing with accordance to recipe accepted in your country. - Number of different aggregates : 4-5-6 - Mobility : Stationary and Mobile type - Capacity offered : 80 - 120 - 160 tph - Hot asphalt storage bunker : optional - Bitumen tanks : you can purchase from us, as well as from domestic market - Aftersale Service : can be provided from Turkey and Algeria - Operation System language : English - Russian - Turkish - French You can contact us any time. We can speak in English, Russian, Turkish, French and Arabic to make you feel comfortable.

Request for a quote

LEGO GREENHOUSE COMPANY

Turkey

Keeping the climate in agriculture under control and ensuring its continuity of the production is provided by greenhouse cultivation. Increasing demands and developing agricultural technologies have contributed to the emergence of soilless agricultural greenhouses. Soilless agriculture, which can be carried out by various methods, provides higher productivity compared to soild greenhouses in terms of cost, but high productivity compared to soild greenhouses in terms of production volume. Plants grown in hydroponic greenhouses take the nutrients from the soil from nutrient alloys. Its popularity is increasing day by day. These advantages cause the increases of the soilless greenhouse preference in lettuce cultivation.The fact that the need for nutrients is low and its consumption is high, the amount of the product obtained is higher than the traditional greenhouses, are the reasons why soilless greenhouses are preferred in the cultivation of lettuce.

Request for a quoteResults for

Products for plants - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Crushing and grinding machinery (3)

- Concrete preparing - machinery and equipment (2)

- Chemical industry - machinery and equipment (1)

- Agricultural Production (1)

- Agricultural machines and accessories (1)

- Agriculture - Machines & Equipment (1)

- Construction - Machines & Equipment (1)

- Conveyor systems (1)

- Flour milling - machinery and equipment (1)

- Flour-milling (1)