- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- construction

Results for

Construction - Import export

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Steel construction, metal, etc. with a high production capacity. It is the type of sandblasting machine preferred by companies in the production sector. The conveyor system is designed as trolleys carrying hanger hooks on a linear line. Different conveyor types are preferred according to light and heavy materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 240 m3/hours stationary concrete batching plant is an industrial facility, primarily engaged in construction, designed for the production of a large quantity of concrete at the pace of 240 cubic meters per hour. This type of plant is appropriate for large construction projects where a great and regular quantity of concrete supply is called for to adequately meet the demand of the project. The standard input includes the cement silos, the aggregate bins, a cement mixer, and advanced control systems, all combining to deliver accurate blending of raw materials that include cement, aggregates, water, and other additives in very specific proportions. The great production capacity of 240m3/hour stationary concrete batching plant makes it an excellent instrument for projects requiring a fair amount of constantly produced concrete to support various construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

PSC200 200 m3/hours stationary concrete batching plant is an advanced industrial setup; it is solely designed for highly voluminous concrete supplies to construction projects at a rate as high as 200 cubic meters per hour. An example project that could make use of such a developed plant would be in doing massive projects that are highly dependent on a steady supply of concrete. It comprises some important parts like cement silos, aggregate bins, a cement mixer, and a control system. These components work in tandem to proportion raw materials such as cement, aggregates, water, and additives in specific ratios, thus leading to high-quality concrete mixes, serving in very dissimilar constructions. A 200m3/hour capacity batching plant for concrete is very helpful for a high volume project with the same quality of processed concrete.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A stationary concrete batching plant of 120 m³/h is a construction facility that helps in producing high quantities of concrete, i.e. 120 cubic meters, each hour from the output. It is a plant used in large construction sites or just about any site that requires huge levels of concrete output within a short timeline. It brings together the following raw materials: cement, aggregates, water, and additives in designed proportions in order to produce high-quality concrete mixes that will meet respective specification requirements for construction. With the inclusion of equipment such as a set of cement silos, aggregate bins, a cement mixer, and a control system for a 120 cum/hour production unit, we ensure that continuous production of concrete meets the demand that is usually experienced in large construction projects. These include the cement silo, aggregate bins, and control system, which allow for the mixing process in which exact raw material proportions are combined to generate

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 100m3/hour stationary concrete batching plant is a rather sophisticated construction facility for producing concrete at a very high rate of 100 cubic meters per hour. This plant is typically used in large construction projects wherein the consumption and volume demand of concrete are notably high. The plant mixes various raw materials—cement, aggregates, water, and additives—in correct proportions to yield high-quality concrete mixes that can be used in numerous construction applications. A 100m3/hour concrete batching plant essentially comprises cement silos, aggregate bins, a cement mixer, and an advanced control system to continuously feed in concreting. These plants are equipped with advanced technology and automation, which can hold up to accuracy in batching and mixing, exercise effective control of the mixing process, and regulate the discharge of ready-mixed concrete.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A PSC60 enterprise-oriented concrete batching plant is a stationary facility for production at an hourly rate of 60 m³/hour. It is of prime necessity for medium and large construction works requiring a constant supply of high-grade concrete. The plant combines an efficient combination of cement, aggregates, water, and additives into an integrated mixing unit for the production of concretes, meeting the most rigorous demands of modern construction. The unique advantage of the PSC60 model is the application in projects that entail a constant volume of concrete within a long period of time. The infrastructure tasks performed with this plant, from roads and bridges to the construction of vast buildings, will be backed with the necessary reliability and efficiency to hold the project to its deadline. It is stationary in its design, making it possible to be installed in only one spot, which is ideal for long-term construction projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A PSC30 30 m3/hour stationary Concrete Batching Plant is a concrete production facility fixed in one location for the production of 30 cubic meters hourly. Stationary plants like these are mostly used in construction projects where a continuous supply of high-quality concrete is needed. More to the point, it consists of elements such as cement silos, aggregate bins, cement mixers, and a series of control systems; through a process of mixing, it combines materials such as cement, water, aggregates in the form of sand and gravel, and a whole range of admixtures to form concrete. PSC30 and lots of other batching plants are designed to provide efficiency, reliability, and accuracy in producing concrete. The PSC30 is a stationary concrete batching plant that produces 30m3/h, hence being critical to construction projects where there is a continuous and reliable on-site supply of newly mixed concrete.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A stationary batching plant is a large setup of an equipment meant for the purpose of producing concrete at even close intervals of time. It is fixed at one place and installed for a larger period of time. This stationary batching plant has capacity output for a high amount of concrete, making it suitable for massive infrastructure works and/or skyscrapers and big business structures. Conceived and built to last and consistent in operations such that it can work around the clock if need be. Where aggregates bins, conveyors, cement silos, a mixing unit, and a control system are important components of the plant, other equally essential elements represent the plant's technology level, which enables it to perform quality and accurate batching. The stationary plant does not provide easy mobility, as is the case with the mobile one.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Such an amount of concrete prepared at the rate of 160 cubic meters per hour is usually required in large-scale projects that have a fairly large daily consumption for the same, done in an order and efficient manner. There are plant parts, including cement silo, aggregate bins, cement mixer, and a control system—all working together to secure proper combination of such necessary materials like cement, aggregates, water, and additives in proper proportions—of future high-quality concrete mixes, applicable to a wide range of construction works. This stationary concrete batching plant has a jaw-dropping production capacity of 160m3/hour, making it ideal for huge concrete requirements in some big projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Stonebox Hopper is a kind of storage container that is frequently used to store and move bulk materials including stones aggregates and other hard materials in the mining quarrying and construction industries. These hoppers are made especially to efficiently handle abrasive and heavy materials. The word Stonebox suggests that it is ideal for working with heavy rough stones or comparable materials. For the materials kept inside of them to cause impact and abrasion stonebox hoppers are usually built with a sturdy construction. Their role in overseeing the handling of bulk material storage and transportation in industrial processes is crucial. In real-world settings Stonebox Hoppers serve as a loading and storing unit for the orderly transfer of materials onto conveyors or downstream processing machinery. A consistent flow of materials is ensured onto the conveyor system for additional handling by the features built into these hoppers that make loading and unloading easier.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A monoblock welded cement silo, also known under the name of mineral silo, is an industrial storage used for storing cement, minerals, or any other granulated material. These silos are developed as a one-piece, monoblock welded structure so that they are strong, compact, and resistant to environmental factors. Mineral silos perform the ideal function of storing materials in a well-ordered way and also providing maximum security in industries like construction, mining, and manufacture. Normally, the monoblock welded cement silo adopts a sealed construction, which can keep stored materials from rainwater, dust, and other impurities that might affect the quality. The monoblock welded silos come in different sizes and capacities to meet various storage needs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

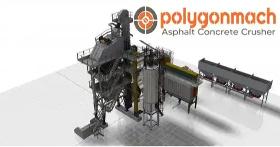

Hot mix asphalt plants can be configured in a variety of ways to suit the needs of different projects. The main varieties are portable mobile and stationary plants each has a special benefit depending on the size and specifications of the building projects it supports. Because of their steady setup and high production capacity stationary plants—which are fixed at a single location—are perfect for big long-term projects. On the other hand plants that are mobile or portable provide flexibility and mobility enabling them to be quickly moved to various job sites. This makes them appropriate for smaller more dynamic projects or those that need frequent site changes. This adaptability is best demonstrated by Polygonmachs mobile or portable hot mix asphalt plant. These plants are lightweight portable and quickly assemble they require little work to assemble disassemble and move.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

This cutting-edge high-capacity PBA 140–160 TPH Stationary Asphalt Plant produces premium asphalt for large construction projects. This plants 140–160 tons per hour production capacity guarantees dependable and effective operation. guaranteeing a steady supply of excellent asphalt that because it is made to exact specifications for large-scale projects expedites the construction process. With exact control over the production process this plant guarantees that the asphalt produced satisfies industry standards. Roads highways and commercial complexes can be constructed with the help of the PBA 140-160 TPH Stationary Asphalt Plant which consistently produces high-quality asphalt. Its creative design and effective operation make it a priceless addition to any significant construction project.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Discover the world of efficient asphalt production because of Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant asphalt produced for large-scale construction projects will be produced differently. These cutting-edge instruments can optimize the asphalt production process which makes them an invaluable asset for large-scale construction projects. The PBA 120–140 TPH Stationary Asphalt Plant is covered in great detail in this article along with information on its assembly process and special features. What is the PBA 120-140 TPH Stationary Asphalt Plant like? We guarantee its dependable and effective operation. Because exact control is maintained throughout the entire production process every batch of asphalt produced by this plant is guaranteed to meet the highest industry standards. The PBA 120-140 TPH Stationary Asphalt Plant is perfect for highways and commercial buildings because it ensures the longevity and functionality of the built roads and structures.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Polygonmachs 60-80 TPH Stationary Asphalt Plant is Revolutionizing the Construction Industry The 60–80 TPH Stationary Asphalt Plant from Polygonmach is revolutionizing the construction sector. In addition to providing outstanding quality this cutting-edge technology promises effective operation and a step toward sustainability. Your projects will benefit from your investment in the future of asphalt production by incorporating this state-of-the-art plant. Picture a building site where the asphalt is produced with unparalleled dependability and accuracy. With a focus on efficiency and waste reduction Polygonmachs stationary asphalt plant guarantees that each batch satisfies meticulous standards. This is a paradigm shift in the way we approach construction not just an upgrade making every project more efficient and eco-friendly.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

100-150 tph Riverstone Crushing and Screening Plants are special plants that are intended for processing Riverstones into aggregate in-crushed-stone-quality needs within a throughput capacity range of 100 to 150 tons per hour. The plants would have primary crushing equipment, screening tools, conveyors—all critical units designed specifically to handle Riverstone material efficiently. Primary crushing includes crushers like jaw crushers or cone crushers that break the larger size of Riverstones into smaller pieces in preparation for the subsequent processing stages, specified in the throughput capacity. The screened material through primary crushing goes to screening equipment, such as vibrating screens, whose task is to classify the Riverstone aggregates by size into fractions. All this is an outcome of rigorous screening processes that lead to the making of aggregates in strict adherence to quality standards, which are put to use in countless construction, landscaping, and industrial

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 150-250 TPH Dolomite Crushing Screening Plant is an installation designed to treat specially dolomite-bearing ore. After processing through crushing and screening, dolomite is produced in different aggregate sizes that find target applications. The abbreviation "TPH" expands into "tonnes per hour," asserting this plant's capacity to treat 150-250 tonnes of dolomite ores on an hourly basis. Dolomite is a type of double-carbonate mineral. Such a composition of calcium magnesium carbonate has immense use, mostly in the construction industry, both of concrete aggregates and in the manufacture of road-based materials. Such plants are involved in the effective crushing and screening of dolomite ore for the production of quality aggregates, which form the fundamental ingredients for infrastructure construction works where supply has to be ensured.

Request for a quote

BACA MAKINE LTD.

Turkey

Welded components are all manufactured according to ISO standards.

Request for a quote

YALÇIN BORU GEOTHERMAL

Turkey

The steel pipes used in the manufacturing of pre-insulated pipes are manufactured longitudinally welded (ERW) or spirally welded (SAW) in accordance with the norms required by the standard TS EN 253 or customer demands. Pipes comprise three basic materials. Carrier pipes are established as steel, copper or plastic based according to the properties of the carried fluids. Casing pipes are manufactured from high density polyethylene (HDPE) raw material, with UV resistance, 100% waterproof and with online corona. PUR ( POLYURETHANE INSULATION MATERIAL) that is injected between the carrier pipe and casing pipe provides heat insulation besides enabling two pipes operating as one pipe by bonding them together.

Request for a quote

SEFINE TEKNIK MAKINE

Turkey

Fabrication Details Diameter : 12 mm – 120 m Dimension : According to the project specifications Standard : 8.8 and 10.9 quality with ST37 and ST42 material Areas of Application Civil Construction Steel Construcion Bridges Steel structure truss bars and y-branches

Request for a quote

SEFINE TEKNIK MAKINE

Turkey

Fabrication Details Thickness : 0.60 mm - 16.00 mm Dimension : 10X10 - 400X400 mm 300x500mm Length : 4 - 15 meter Standards : TS : 416 (TS EN 10217-1), 6476, 6475, 5317, EN 10305-5, 5317, EN 10219-2 DIN : 2394 - 2395 BS : BS EN 39 :2001, 6323, 6363, EN10219-2, EN 10305 ASTM : A500, A513 Areas of Application : Civil Construction Works Works Mechanical Steel Construction Bridges Steel Structures

Request for a quote

KAYGUN STEEL METAL IND. TRADE CO. LTD.

Turkey

Steel Construction

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

4800 L Vertical Waste Dil Tank is specially designed for storage and transportation of hazardous chemicals in offshore environment. it is mounted on skid for stability and to withstand dynamic lifting and impact forces in harsh sea conditions

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

TNR Prefabrik offers all kinds of mobile building solutions for all special and institutional demands. Our team that produces more innovative solutions every day with the experience of years, has been pilot works in prefabricated building sector.

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

While aiming to create structures for the future with KATKON Multipurpose expandable units, it was possible to reduce the costs by reducing the deficiencies in the sector, to save time, and to fit the living areas up to more than 3 times the size of the unit area during transportation.

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

TNR Prefabrik responds quickly to needs by producing fully equipped Mobile Hospitals for commercial, disaster and military applications.

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

Waste Skip Container designed for the safe and efficient transportation and storage of general waste

Request for a quote

TNR PREFABRIK CONSTRUCTION MARKET

Turkey

45x4 ft Open Top Basket Container specially designed for transportation of equipmant that required loading by crane

Request for a quoteResults for

Construction - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Concrete constructions (12)

- Construction Materials (5)

- Offshore construction (5)

- Offshore contractors (5)

- Tar and asphalt - construction materials (4)

- Bridges - construction (3)

- Crushing and grinding machinery (3)

- Construction machinery (2)

- Galvanization - steels and metals (2)

- Buildings, prefabricated (2)

- Mobile homes (2)

- Onshore and offshore services (2)

- Steel, structural (1)

- Buildings, modular (1)

- Building materials (1)

- Tunnel construction (1)

- Steels and metals - welding and brazing (1)

- Steel (1)

- Concrete mixers (1)