- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- additions

Results for

Additions - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

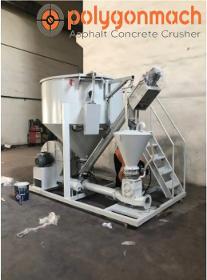

The Asphalt Fiber Granule Additive System is a modern, pre-engineered component assembled in asphalt plants for the introduction of fiber granules into asphalt mix with needed precision and control. These fiber granules play a vital role in strengthening asphalts against cracking, rutting, and other distresses. Fiber granules enhance the durability and performance of asphalt pavements, allowing them to sustain increasing volumes and intensities of traffic without being affected by various harsh weather conditions. The system is critical in the manufacture of high-quality asphalt mixes qualified enough for modern infrastructure. The effect of adding fiber granules into an asphalt mix is reinforcing; much the same way rebar does in concrete. This reinforcement allows such loads to distribute further out in the pavement, minimizing the chances of damage with time.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A PSC30 30 m3/hour stationary Concrete Batching Plant is a concrete production facility fixed in one location for the production of 30 cubic meters hourly. Stationary plants like these are mostly used in construction projects where a continuous supply of high-quality concrete is needed. More to the point, it consists of elements such as cement silos, aggregate bins, cement mixers, and a series of control systems; through a process of mixing, it combines materials such as cement, water, aggregates in the form of sand and gravel, and a whole range of admixtures to form concrete. PSC30 and lots of other batching plants are designed to provide efficiency, reliability, and accuracy in producing concrete. The PSC30 is a stationary concrete batching plant that produces 30m3/h, hence being critical to construction projects where there is a continuous and reliable on-site supply of newly mixed concrete.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The MCA 140-160 tph Continuous Type Asphalt Plant represents the latest technology in asphalt producing plants, especially engineered to provide extra capacity and efficiency for medium-to-high-volume projects. In these advanced plants, high-quality asphalt mixes are produced with uniformity—the challenging requirements expected of road construction. It has a production capacity ranging from 140 to 160 tons per hour, hence making this a versatile and reliable solution for many various applications. The design is user-friendly in the sense that one gets precision, performance, and durability, thus making this an ideal choice for use in different construction needs. The MCA 140-160 tph plant is designed to fit demanding requirements by advanced technology with sturdy construction. Such machines are outstanding in asphalt production, offering quality for all jobs and reliability in functioning.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The MCA 100-120 tph Continuous Asphalt Plant is the technology pioneer in asphalt production, offering best-in-class efficiency and performance for medium to high-volume projects. This continuous asphalt plant is durable and fully equipped with advanced characteristics that enable quality continuous asphalt mixture production. It offers a range of production capacities from 100 to 120 tons per hour, which deals with a wide variety of road construction applications. This plant is designed for the production of asphalt for any requirements with the ultimate accuracy and consistency of results. The power-packed MCA 100-120 tph plant, standing out to be the strongest of its kind in construction and ultra-modern technology, is suitable for all projects from highways to luxuriant urban roads and on to industrial zones. It can produce numerous sorts of asphalt mixtures, including those needed for base, binder, and surface courses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

MCA 80-100 tph Continuous Type Asphalt Plant is a technologically advanced machine to produce asphalt mixes continuously in the medium to high category of volumes. As the name suggests, this plant has been designed with pinpoint accuracy and efficiency, merging state-of-the-art technology with strong, durable construction, to achieve continuous and uninterrupted production of consistent, high-quality hot-mix asphalt. It can produce between 80 to 100 tons per hour, adequate for many road construction projects. Compact design of the plant provides reliability and maximum performance, besides being user-friendly. Furthermore, it is versatile and cost effective for asphalt producers because it is splendidly modular in construction, with easy installation, transportation, and customization. This plant is designed for a wealth of applications in road construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

User Experience The Polygonmachs 120-140 TPH mobile asphalt plant is designed to provide an exceptional user experience. Its primary features are quick deployment and easy operation for a seamless project start. Because of its exceptional mobility site transitions can be ensured swiftly and seamlessly. The plants user-friendly control system makes it easy for operators to monitor and alter the asphalt production process. Due to the ability to optimize mix formulations and parameters to meet specific project requirements this ensures efficient production of asphalt under a range of conditions. Because of its flexibility the plant can also adjust to a range of conditions. This plant can be used for jobs that need it to be moved around a lot or set up fast in isolated locations. Its streamlined design and operational efficiency ensure that production can start almost instantly upon arrival at any site making it a flexible and reliable option for contractors.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Hot mix asphalt plants can be configured in a variety of ways to suit the needs of different projects. The main varieties are portable mobile and stationary plants each has a special benefit depending on the size and specifications of the building projects it supports. Because of their steady setup and high production capacity stationary plants—which are fixed at a single location—are perfect for big long-term projects. On the other hand plants that are mobile or portable provide flexibility and mobility enabling them to be quickly moved to various job sites. This makes them appropriate for smaller more dynamic projects or those that need frequent site changes. This adaptability is best demonstrated by Polygonmachs mobile or portable hot mix asphalt plant. These plants are lightweight portable and quickly assemble they require little work to assemble disassemble and move.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The pinnacle of productivity and innovation in asphalt manufacturing can be found in Polygonmachs PBA 320–400 TPH Stationary Asphalt Plant. Large-scale construction projects are the target market for this cutting-edge machinery which streamlines operations and maximizes the entire production process to deliver superior results. This page examines PBA 320-400 TPH Stationary Asphalt Plants key features assembly process specifications and unique selling points. One type of high-capacity equipment used to create high-quality asphalt for large construction projects is the PBA 320–400 TPH Stationary Asphalt Plant. The robust requirements of major infrastructure projects like highways airports and industrial sites are what this plant is designed to withstand. It can generate between 320 and 400 tons of asphalt per hour. Even the most ambitious projects will be successfully and on schedule thanks to the projects high production capacity.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

You can embark on an efficient asphalt production journey into the future. Designed to transform the asphalt production process Polygonmachs PBA 240-320 TPH Stationary Asphalt Plant offers unparalleled quality and efficiency for major construction projects. High-volume asphalt projects benefit greatly from this state-of-the-art equipment because it guarantees optimal performance. We will examine the features parts assembly procedure and special benefits that distinguish the PBA 240-320 TPH Stationary Asphalt Plant from its rivals in this article. What is the PBA Stationary Asphalt Plant with 240-320 TPH Capability? This plant which can produce between 240 and 320 tons per hour ensures steady effective operation—a necessary quality for keeping up the pace of big projects. This facility is designed to withstand the rigorous specifications of building projects like building highways airports or industrial complexes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Large-scale construction projects require asphalt of the highest caliber which is why the PBA 200-240 TPH Stationary Asphalt Plant has a high capacity. This plant which can produce between 200 and 240 tons per hour guarantees dependable efficient operation which is essential for maintaining the momentum of large-scale projects. This plant is built to withstand the rigorous requirements of construction projects be it highways airports or sizable industrial complexes. By carefully regulating the production process this plant excels in producing asphalt with exceptional quality. The PBA 200-240 TPH Stationary Asphalt Plant produces a product that is dependable and long-lasting by making sure that every batch satisfies stringent industry standards. In order to produce asphalt that can endure the rigors of heavy traffic and variable weather conditions assuring long-lasting performance and safety a high degree of precision and quality control is imperative.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With Polygonmachs PBA 80-100 TPH Stationary Asphalt Plant Explore the Future of Efficient Asphalt Production Significant construction projects are experiencing a revolution in the production of asphalt thanks to Polygonmachs PBA 80-100 TPH Stationary Asphalt Plant. This top-of-the-line machinery is ideal for large-scale projects because it is made to maximize every facet of asphalt production. In-depth discussions of the PBA 80-100 TPH Stationary Asphalt Plants parts assembly procedure and distinctive features that make it stand out in the industry are provided in this article. What is a Stationary Asphalt Plant (PBA 80-100 TPH)? It is especially designed to generate 80–100 tons of asphalt per hour guaranteeing a reliable and effective operation that satisfies the demanding requirements of major building projects.This plant strives to maintain quality throughout the production process making sure that every batch of asphalt meets strict industry standards in addition to producing

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Asphalt Fiber Granule Additive System is a modern, pre-engineered component assembled in asphalt plants for the introduction of fiber granules into asphalt mix with needed precision and control. These fiber granules play a vital role in strengthening asphalts against cracking, rutting, and other distresses. Fiber granules enhance the durability and performance of asphalt pavements, allowing them to sustain increasing volumes and intensities of traffic without being affected by various harsh weather conditions. The system is critical in the manufacture of high-quality asphalt mixes qualified enough for modern infrastructure. The effect of adding fiber granules into an asphalt mix is reinforcing; much the same way rebar does in concrete. This reinforcement allows such loads to distribute further out in the pavement, minimizing the chances of damage with time.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Such an amount of concrete prepared at the rate of 160 cubic meters per hour is usually required in large-scale projects that have a fairly large daily consumption for the same, done in an order and efficient manner. There are plant parts, including cement silo, aggregate bins, cement mixer, and a control system—all working together to secure proper combination of such necessary materials like cement, aggregates, water, and additives in proper proportions—of future high-quality concrete mixes, applicable to a wide range of construction works. This stationary concrete batching plant has a jaw-dropping production capacity of 160m3/hour, making it ideal for huge concrete requirements in some big projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Mobile Cement Silo on Wheels is a moving storage tank for cement storage and delivery to various job sites. Unlike the traditional stationary cement silos, the mobile version is mounted on wheels or trailers for easy movement from one location to another. Depending on the model and the needs of the job, they could store tens to hundreds of tons of cement. Mobility offers a number of advantages by way of flexibility in deployment and quick setup at construction sites. The mobile cement silos can easily be relocated to different parts of a job site to allow easy access to cement from any point it might be required. This makes them ideal for construction projects with shifting demands or multiple work zones. Also, the fact that it is movable from one project to another eliminates multitudes of storage facilities around a site; hence, time and money are saved.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A horizontal low-level silo is specially designed for the purpose of containing bulk amounts of cement situated at ground level. Unlike the traditional towering vertical silos, these low-lying silos are laid horizontally and are pretty accessible for activities related to maintenance, inspection, and loading. It is a horizontally designed, low-level cement silo operating very easily and efficiently once installed into the concrete batching plant on-going with the supply of cement into the plant for production. This is used for storing cement close to the point of use so that cement may be loaded in mixers easily and quickly for the production of concrete.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MINE COLOURS

Turkey

Ultraviolet Masterbatch Anti-Slip Masterbatch Optic Bright Masterbatch Masterbatch Application: Mine Colours can provide colour and additive masterbatch options for agriculture industry. Greenhouses requires ultraviolet resistant plastic additives as well as optic bright masterbatches for the longevity of the greenhouse. Thank to our vast experience from working closely with Turkey’s leading greenhouse manufacturers, we can provide necessary plastic additives and colours for agriculture industry.

Request for a quote

MINE COLOURS

Turkey

Colour masterbatch for PET Packaging Products Mine Colours offers a wide range of innovative additive masterbatch dispersions for a variety of applications. These additive masterbatches are used with a broad range of polymers that are ultimately used to optimize processes and for finished package performances. These Masterbatches are specifically manufactured for the needs of food, greenhouse, beverage, and medicine industry. Special ultraviolet stabilizers and absorbents are used together to prevent loss of moisture, taste, and color of food due to UV exposure of the sunlight.

Request for a quote

MINE COLOURS

Turkey

Colour Masterbatch for PET Bottles for medicinal purposes Masterbatch Applications: We offer colored PET Masterbatch which are suitable for prescription bottles which require hiding power to avoid sunlight affecting the packaged products. Colored PET for prescription bottles used in medical and pharma packaging.

Request for a quote

MINE COLOURS

Turkey

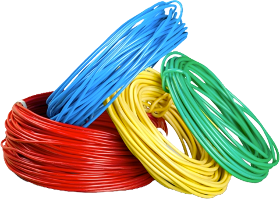

Masterbatch Applications: Mine Colours offers comprehensive product range and have vast experience in designing fully tailored formulations based on specific customer requirements. We've proven our capability to deliver products meeting exacting standards and providing materials with the necessary functional requirements of electrically insulating, heat-resistant, flame-retardant, water-repellent, weather- and radiation-resistant properties for innovative electrical insulation materials.

Request for a quote

NEOSYS SURGICAL SOLUTIONS LTD.

Turkey

As Neosys Surgical Solutions LTD- a DOGUS COMPANY , We are working over a decade in the sport medicine (arthroscopy) and trauma products. We are the manufacturer for this product groups. As we are " Neosys ", we are looking for new distributors. We would be very satisfied to have a collaboration with you. If you interest to our product please inform me. OUR PRODUCTS AS FOLLOWS: -Titanium or Peek suture anchors with fiber suture 5.0mm ,2.8mm, 3.5mm , 2.0mm -endobutton (for acl surgery ) -Fiber suture with needle -Peek knotless anchor -MTP prothesis -Trauma plates and screws for mini fragments. -sodium hyalarunate gels for articular injection. -peek interference screws -Cannulated screws -Headless full threaded compression screws -Spinal products tolga bolat tbolat@neosysmed.com

Request for a quote

FEEDADDS

Turkey

To maintain the welfate and proper functionalities of poultry liver against toxic effects. Indications -H-TONIC is a special product designed for helping the proper functions of liver in metabolism, detoxification, secretion, productivity, and acts as hepatoprotective and hepatoregenerative. It protects the liver against toxic effects, chemical drugs, an various toxins. -H-TONIC achieves rapid regeneration of liver tissues and cells, restore the liver functions and reduce effects of mycotoxins.

Request for a quote

FEEDADDS

Turkey

Prımary Functıon Effective in fatty liver syndrome and improves the animals' overall liver function. Indications -Prevents fatty liver symdrome and improves liver functions. -Improves carbohydrate metabolism for proper functioning of nervous tissue, cardiac muscle and enzyme activities. -Important role in metabolism, growth rate and feed utilization. -Stimulates regeneration of hepatic cells and better productivity

Request for a quote

FLYCHEM

Turkey

As Fly Kimya, we have been producting foam polyuretane and polyurea for many years. We export polyurethane and polyurethane raw materials to more than 30 countries around the world. In the new year, we have expanded our product portfolio with other raw materials such as PMDI, MDI, TDI, etc. Sectors in which we mainly sell products: insulation companies, construction companies, shoe sole manufacturers, foam mattress manufacturers, sandwich panel manufacturers, etc.) In addition to supplying raw materials, we also manufacture sandwich panels and polyurethane spraying machines. Our raw material and sandwich panel factory is located in Istanbul. Our polyurethane spray gun manufacturing machine and warehouse are located in Kayseri.

Request for a quote

BETRA BIO

Turkey

COMPLEMENTARY FEEDS FOR ANIMALS

Request for a quoteResults for

Additions - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Tar and asphalt - construction materials (10)

- Additives for plastics industry (5)

- Additives, cement and mortar (2)

- Concrete constructions (2)

- Livestock and poultry - feed (2)

- Medicine - basic products and additives (1)

- Food for livestock and poultry (1)

- Cement-making - machinery and equipment (1)

- Cements, special (1)

- Animals & Livestock (1)

- Construction Materials (1)

- Polyethylene (1)

- Bulk materials for construction (1)