- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor

Results for

Conveyor - Import export

AUROMAK MAKINA

Turkey

The tunnel-type hot water and multi-purpose washing, rinsing, drying and lubricating system is an effective cleaning and treatment method of ten used on a large scale in industrial production processes. This system is located inside a tunnel where materials move automatically on a convey or belt.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

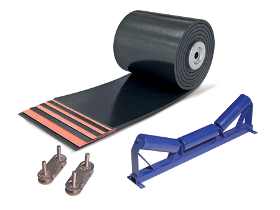

Stock conveyors can be produced as radial type according to the location of the facility, land conditions and customer demand. The Belt Conveyor chassis is connected to the ground from the tail module with a fixed joint. High-strength steel construction feet made to support the weight of the intermediate modules and the drive module are attached to the axle located on the wheels. These wheels are preferred as filled wheels in order to be loose-proof. The gearbox is driven by a coupled motor. It is equipped with a special brake system to prevent movement due to environmental effects during operation or stopping. The center of rotation is the fixed hinge point in the tail module. It is provided to turn clockwise and counterclockwise by the angle allowed. In this way, the stock amount is much more than a fixed stock belt conveyor.

Request for a quote

SALEX GLOBAL TRADING CO

Turkey

flour feed mill machinery, turnkey solutions, roller machine, drum detacher, jet filter, scourer, vibrating air cycle, air channel, vertical washer, trieur, hammer mill, blower pump, elevator, conveyor, hexagonal,

ROBINSON CO.

Turkey

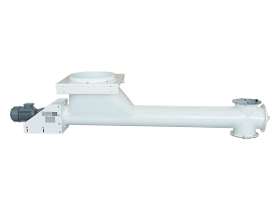

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

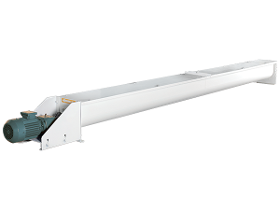

The Tube Screw Conveyor, which is used in grain, grain and food processing plants transportation equipment, is used for horizontal and vertical transportation of powdered or very thin products. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chains

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: DQ09841 Model: 1450/1550 CWS/WTS Brand: Donghua

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Automatic Distribution Conveyor possessing a Shuttle Type design is a sophisticated material handling system applied in warehouses, distribution centers, and manufacturing facilities. This equipment is primarily engineered to automate the sorting and distribution of items along a conveyor line. Unlike the other systems, this system has a shuttle mechanism that runs across the entire width of the main conveyor, picking items up and transferring them transversely to specific offloading locations. It operates independently of the main conveyor and can handle the accurate transferring of items depending on their destination, size, weight, or any other parameter that needs to be considered. Incorporate this shuttle mechanism to improve the total efficiency and accuracy of the system in handling materials and automate the flow of goods through various processes from processing to shipping.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In industrial environments a combination feeding hopper and dosing belt conveyor is a frequently utilized system for regulated material feeding and dosage. Before raw materials or bulk materials are fed onto the belt conveyor they are first stored in the feeding hopper. In order to enable accurate material distribution and consistent dosing it guarantees a constant and continuous supply of materials to the dosing belt conveyor. Transporting and dosing materials at a regulated rate however is the job of the dosing belt conveyor. The technology is appropriate for batching mixing or processing operations that call for precise material dosing because it can control the conveyor belts speed and capacity to precisely dispense the required quantity of materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Telescopic Radial Conveyor Belt Radial Stacker is a specialized equipment used in material handling applications to efficiently stack bulk materials in radial patterns. This equipment combines the functionalities of a telescopic conveyor belt and a radial stacker to offer enhanced flexibility and efficiency in material stacking operations. The telescopic feature allows the conveyor belt to extend or retract, enabling it to reach varying distances for stacking materials, while the radial stacking capability enables the creation of organized radial stockpiles of bulk materials. By integrating telescopic and radial functionalities, this equipment optimizes material stacking processes and enhances storage capacity within a limited space footprint. The operational principle of a Telescopic Radial Conveyor Belt Radial Stacker involves extending the telescopic conveyor belt to reach the desired stacking location and efficiently conveying materials to create radial stockpiles.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A specialized conveyor system called a telescopic radial stacker is used in material handling applications to stack bulk materials in radial stockpiles with efficiency. This equipment has an extendable and retractable telescopic boom that expands its reach and facilitates radial or circular material stacking. By utilizing the radial stacking feature the stacker can maximize storage capacity in a constrained footprint by forming stockpiles with a larger diameter.Effective bulk material management and storage is achieved through the widespread use of telescopic radial stackers in the mining construction and aggregate processing industries.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROBINSON CO.

Turkey

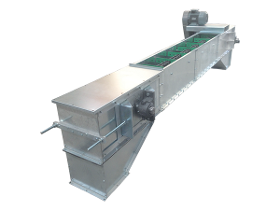

Depending on the central control, it takes action by being set up with chain gear and ensures the transportation of the falling product. The body is made of steel. It has idler drive bearing system. It has been designed with a special tensioning device. It varies according to the desired capacities. Carrier plates are made of hardened steel. It is used wherever horizontal transportation is possible. It is used in feed, food, chemical, mining, sawdust and soil industries. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

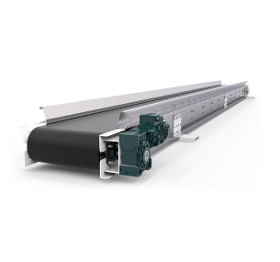

It transports the bagged product from one place to another, the combined belt conveyor supports the belt conveying process. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is a conveyor belt system with general ease of use that can be used in any area where loading and unloading operations are performed, provides convenience in terms of occupational and worker health, minimizes damage to products. It provides convenience in stacking and storage. It can be used as highly adjustable, stationary and mobile (mobile). Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories ◾ All Transport Operations

Request for a quote

ROBINSON CO.

Turkey

It is generally used as a dust collector, dust and air separator for the product. It is found in aspiration systems of cleaning machines. Dust removed by aspiration is separated from the air by means of a cyclone. The dust-laden carrier air is directed inside the separator thanks to the helical construction and is forced to rotate in the cyclone. Dust particles are dispersed to the environment with the effect of centrifugal forces arising due to rotation. Dust particles are carried along a helix path by means of the vortex created by the air pushed from behind. The clean air separated from the dusts goes through the suction pipe and goes to the outlet. Dust particles are directed downwards along the spiral due to the friction of the air against the wall. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 100m3/hr mobile portable concrete batching plant is a pre-engineered, multipurpose facility in the field of medium- to large-scale construction projects. With a production capacity of 100 cubic meters of concrete per hour, such mobile plants can easily meet the high concrete demand requirements for any construction endeavor. It is portable, which enables the plant to be easily shiftable from one job site to another, enabling quick setup and on-demand concrete-making that caters to specified needs. A 100m3/hour mobile portable batching plant incorporates aggregate storage bins, cement silos, a mixer unit, and a control system, providing a strong and versatile solution for construction projects that require high concrete production capacities. These values, together with its highly advanced features and maximum production capacity, are up to 100m3/hour, making a mobile portable concrete batching plant very helpful for almost all kinds of construction work.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A stationary batching plant is a large setup of an equipment meant for the purpose of producing concrete at even close intervals of time. It is fixed at one place and installed for a larger period of time. This stationary batching plant has capacity output for a high amount of concrete, making it suitable for massive infrastructure works and/or skyscrapers and big business structures. Conceived and built to last and consistent in operations such that it can work around the clock if need be. Where aggregates bins, conveyors, cement silos, a mixing unit, and a control system are important components of the plant, other equally essential elements represent the plant's technology level, which enables it to perform quality and accurate batching. The stationary plant does not provide easy mobility, as is the case with the mobile one.

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: AZ46269

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: DQ41476 Model: 1450/1470/1550 1570/W330 Brand: Donghua

Request for a quoteResults for

Conveyor - Import exportNumber of results

62 ProductsCountries

Company type

Category

- Conveyor belts (7)

- Pneumatic conveyor equipment (5)

- Harvesting machinery and equipment (5)

- Milling - steels and metals (5)

- Flour-milling (4)

- Stackers (4)

- Bulk materials for construction (3)

- Cement-making - machinery and equipment (3)

- Concrete preparing - machinery and equipment (3)

- Flour milling - machinery and equipment (3)

- Conveyor systems (2)

- Crushing and grinding machinery (2)

- Industrial washing facilities (2)

- Washing equipment for fruits, vegetables and fish (2)

- Conveyors, overhead and floor (1)

- Agriculture - Machines & Equipment (1)

- Chemical industry - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Agricultural machines and accessories (1)

- Concrete constructions (1)