- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- construction quality

Results for

Construction quality - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Mechanical Stabilization Plant: What Is It? In order to enhance the qualities of soil and make it more suitable for constructing infrastructure such as roads highways and airport runways the construction industry uses mechanical stabilization plants. In order to improve the strength durability and load-bearing capacity of the soil binding agents like lime cement or foamed bitumen are blended into the soil. The objective is to produce a uniform stable material that can back the building of long-lasting structures and surfaces. In situations where the native soil lacks the necessary qualities for construction mechanical stabilization plants are crucial. By modifying the properties of the soil these plants guarantee that the foundation is robust enough to support large loads and withstand environmental influences.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 2500-ton horizontal bitumen tank is a huge specially built storage facility designed to store and handle vast quantities of bitumen, a thick and tacky material refined from petroleum. These are special tanks designed with a horizontal axis so that it becomes possible to store, heat, and transfer the bitumen in question. Constructed with quality raw material—steel that guarantees strength in storage for highly demanding bitumen-based material products, thus securing their stability during storage and transportation. The 2500-ton horizontal bitumen tank is used in a number of industries for safe storage to consumers of vast volumes of bitumen. It is designed to maintain bitumen in a workable state such that it is in readiness for use directly in any of the industrial applications, be it in road construction, manufacture of asphalt, or any other waterproofing work.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In order to enhance the qualities of soil and make it more suitable for constructing infrastructure such as roads highways and airport runways the construction industry uses mechanical stabilization plants. In order to improve the strength durability and load-bearing capacity of the soil binding agents like lime cement or foamed bitumen are blended into the soil. The objective is to produce a uniform stable material that can back the building of long-lasting structures and surfaces. In situations where the native soil lacks the necessary qualities for construction mechanical stabilization plants are crucial. By modifying the properties of the soil these plants guarantee that the foundation is robust enough to support large loads and withstand environmental influences. The resulting stabilized soil serves as a dependable base for long-lasting infrastructure and is utilized for a variety of purposes including embankments and road bases and subgrades.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

One of its key benefits is its amazing production capacity. The plant which can produce between 160 and 200 tons per hour ensures that construction teams can comply with quality standards and deadlines. With this high output you can precisely meet deadlines and maintain the projects progress. An additional significant advantage of the plant is the exceptional quality of asphalt it produces. Because of its precise control over the production process asphalt meets the highest industry standards. The end product is therefore of the greatest quality and remarkably durable prolonging the lifespan and usefulness of the constructed roads and structures. Because of its energy-efficient design the plant is a cost-effective and environmentally responsible option for construction projects.Given its emphasis on energy efficiency the plant is a desirable option for modern construction firms aligning with the growing demand for greener construction methods.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

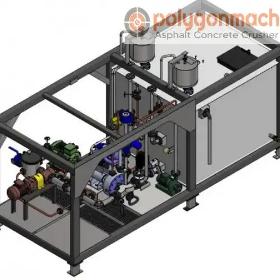

A mortar or concrete mixer is a special type of machinery designed to mix, with high efficiency, the ingredients used in the formulation of mortar and concrete. They are an important piece of equipment for those involved in construction, masonry, and landscaping projects. The blender mixes the ingredients like cement, sand, water, and aggregates with high precision to provide uniform and consistent mixes. The available types of mortar concrete mixers in the market are the drum mixers and the pan mixers; these mixers effectively cater to different project sizes and requirements. Their key task is to mix dry and wet materials effectively in order to obtain a homogeneous mortar or concrete mix produced. Mortar concrete mixers automate the mixing process, which saves construction time and improves the quality of work. Mortar concrete mixers are versatile in what the mixers can perform and are convenient and quick for mixing materials in many forms of construction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Construction quality - Import exportNumber of results

5 ProductsCountries

Company type