- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- concrete structures

Results for

Concrete structures - Import export

ROBINSON CO.

Turkey

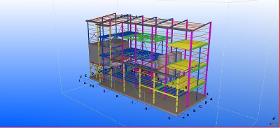

There are several reasons why steel structures are preferred over reinforced concrete structures. The main reasons are fast generation and seismic resistance. Steel structure reduces loss of life and property during disasters and ensures safety. Metallurgical facilities, industrial buildings, sports facilities, hangars, warehouses - these are structures in which metal structures are often used. Light or heavy steel is preferred depending on the project requirements. Since heavy steel is generally preferred in industrial buildings, its load-bearing capacity is suitable for industrial applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 30m3/hour mobile portable concrete batching plant is a compact, versatile facility of concrete production designed to be truly mobile and flexible. This type of plant, which has the feature of producing 30 cubic meters of materials in an hourly cycle, aims to serve small- or medium-scale construction with different scales of needs. The portable mobile design ensures that it can easily be transferred from one place to another, enabling on-site production and delivery for the best service possible on any given project. As much as it is compact and mobile, the 30m3/hour mobile portable concrete batching plant is quickly and effectively erected, ensuring minimum downtime on those construction sites choked by space or found in remote areas. These mean portable plants can have most of the essential components, which could include storage bins for aggregates, cement silos, mixer unit, and a control system to regulate the batching and mixing processes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 50-ton welded type cement silo could potentially be a very large structure for concrete, cement. Those are usually applied and used at construct lines, concrete batch plants, and other industrial projects to store in addition to dispensing such objects. All-welded constancy in design guarantees their permanence and stability in long-term use with different ambient environments. The 50-ton capacity of the silo means the ability to provide a quantity that is possible to be on site well ahead of time to have the requirements of the construction met without delay. Even though the design is welded, the strength it gives is considerable enough for resisting harsh weather and, most importantly, ensures the cements stored therein are maintained safe and ready for fitting at desired times. To sum up, a 50-ton Welded Type Cement Silo- a ready and perfect solution for the storage of cement in required quantities for an ongoing construction project.

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

Exterior design services were provided for the existing concrete structure.

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

Exterior and interior design service were provided for the existing concrete structure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

Glass and composite exterior design and their applications were carried out for the existing concrete structure.

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

Glass, composite and stone exterior design and their applications were carried out for the existing concrete structure.

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

Exterior/interior design services were provided for the existing concrete structure. Decorative Aluminium panels were used for exterior façade.

Request for a quote

UMMANMAK

Turkey

In Skip Hoist Concrete batching plants, the aggregate is transported to the mixer by sliding on the rail with the help of skip hoist. UMMAN manufactures bucket concrete batching plants by using the most durable rope and rail structure as concrete batching plants. Emergency sensors are used against rope breaks. In any unfavorable situation, the skip hoist is stationary by locking the rail.The Automation Software Required for the Control of the Plant is Continuously Developed and Improved by the UMMAN Concrete Software Team, and the Customer's requests are answered in the best possible way.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

Our ZIM 820 machine is a mid-entry machine designed for the production of double-layer paving stones. The ZIM 820 stands out with its low energy consumption, wide choice of production and high return on investment. It can be used manually, semi-automatically and fully automatically if requested. Our machine, which can produce 8 concrete blocks or 20 concrete paverstones in one press, is designed to produce 1000 pallets per day. To facilitate this production and increase quality; It has many features such as internal shaking system in the mortar cart, driver-controlled vibration system, special balancing system on the upper mold, and a specially designed vibration table. We are using “ FULLDRIVE ” frequency controlled vibration systems in our machine. This helps the life cycle of vibration engines and also decreases the total electrical consumption of vibrators.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 PLUS Block and Paverstone Machine is special design machine for block and interlock production that works fully automatic.The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of blocks, paverstones, curbstones, grass stones, lentos and precast concrete elements can be produced in a serial way. 20cm block can be produced 15, interlock paverstones can be produced 36 units in one press. Machine is able to produce the insulated block upon demand. Thanks to special features developed by our engineers machine have very short cycle time. For example mould changing is wery easy and take short tme in new system. Automation system and operator panel which is developed and redesigned in long years become user friendly and useful. With our special design vibration table you can produce high quality products with less energy. We use pneumatic bellows in machine mould connections.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 machine is a high-end machine designed for the production of concrete blocks, concrete paverstones and concrete curbstones. ZIM 1536 comes out with high-end hardware, wide options of production and low labor cost. It can be used in automatic facilities such as FINGER CAR, BASKET SYSTEM, L TYPE SYSTEM. Our machine that can produce 15 blocks or 36 paverstones in one press, is designed to produce 1200-1400 pallets per day. Aiming at maximum capacity with mass production, our machine is designed to work non-stop! Our machine, which can follow the mortar in machine with the loadcell system in the bunkers, takes you to the next level with the proportional mortar car movement, and reaches the maximum quality with the mold balancing and pressing system, is a pioneer in the sector with its many hardwares!

Request for a quote

NOVATEC TEKNOLOJI A.S.

Turkey

For over thirty years, we are manufacturing concrete pipe machines, manhole machines, culvert machines, concrete barrier machines with moulds, pallets and all other equipment in our factory. We have full automatic and manuel models for different users in all sizes. We can also offer turnkey plants for the complete set of machinery for pipes, manholes and culverts with the concrete batching plants and gantry cranes.

Request for a quoteResults for

Concrete structures - Import exportNumber of results

14 ProductsCountries

Company type