- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- arc welding

Results for

Arc welding - Import export

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

There are hydraulic pressing clamps in the fixture equipment of system. The workpiece is both made spot welding by means of clamps and prevented distortion due to heat during welding. Separate control lever is used as to be put to rear of piston for each piston.Also there is a pressure relief valve on each control lever. Thanks to pressure relief valves the critical pressure is brought to the desired pressure and the compression of the material in desired strength may be achieved A lock valve is connected to each hydraulic cylinder after the tightening process and during the welding operation, the material is prevented from being retracted and opened due to heat input. Reverse deflexion may be done on the frame thanks to the control units in the clamp mechanisms. 1 inert gas arc welding machine will be used for spot welding process.( it will be supplied by the purchaser)

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Turn Table, precisely provide to welding by turning clockwise or counterclockwise of parts connected to it horizontally. It also enable movement in the rotation axis. . The work table is operated with a T-slot turntable to ensure that the workpieces are fully fixed to the work table. It is designed with the aim of increasing efficiency, eliminating the need for welding in difficult positions and considering ergonomics of employees.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Access to the workpiece from the outer surface Installation close to the wall edge Linear welding with walking motion Circular welding on the rotating system Motion transfer with linear slides and trolleys Ability to connect welding machine, oxygen and plasma cutting unit Ability to create special applications and stations

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

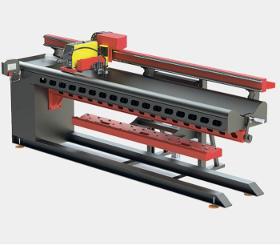

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Being able to walk on a suspended type tank Single-sided tank welding Single operator control 1000 – 3000 mm plate welding Tank welding machine is an automatic tank welding machine designed for welding cylindrical structures that can weld with submerged arc welding in the side position (3 o’clock). The welding unit is fixed on a cabinet. On the upper floor of this cabin, where all safety conditions have been provided for the operator, there are motor and gear systems that move the system on the hardware sheet. Tank Welding Machine enables horizontal circumferential welding of large storage tanks with Submerged Arc welding machine. • The minimum diameter it can weld is 4.5 meters. • The lowest sheet thickness that can be welded is 6 mm. The outer cover is produced to protect the user from the external factors of nature. Our Tank Welding Machine is designed to weld either internally or externally.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Arc welding - Import exportNumber of results

6 ProductsCountries

Company type