- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air curtain

Results for

Air curtain - Import export

PANERA ENGINEERING INC. (PANERA MUHENDISLIK AS)

Turkey

The most intense areas in terms of energy losses of workshops and sales areas are their outer doors. Heated air in the winter and the costly chilled air in the summer are lost through these openings. The larger the doors, the higher the costs due to uncontrollable changes between indoor and outdoor temperatures. It also increases the possibility of airflow between the doors. The ambient temperature is kept under control with the help of air curtains. With this, energy costs decrease and working conditions improve. Technical Features Model AIR WALL 20 Power 21,7 kW Natural Gas Consumption 2,30 Nm3/sa Gas Connection 20-55 mbar Air Flow 1400x3 m3/sa

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our continuous type ovens can be produced as belt tunnel type, internal return (U) type or with span conveyor. Our ovens have the indirect heating thermo-block system with convection heat transfer. It can be manufactured according to power supply sources like electricity, gas or liquid fuel. The inner surfaces of our ovens’ panels are produced with galvanized sheet and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thickness (usually 160 mm) is determined and only rock wool is used for insulation. Air curtains in the furnace are placed inlet and outlet of the oven to minimize heat loss while increasing the efficiency.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

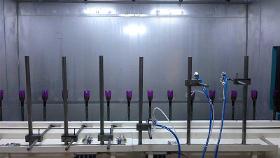

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Air curtain - Import exportNumber of results

3 ProductsCompany type