- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air accessories

Results for

Air accessories - Import export

ILK IHRACAT AS.

Turkey

In industrial processes, we increase your productivity by keeping products or machines in the required internal climate conditions. According to your needs; We increase your production capacity by rapidly cooling your products, We minimize your losses by providing the desired temperature and humidity balance in your production lines, We contribute to your productivity by maintaining your equipment. Get A Quote Email your requirements to info@steeling.net and open the doors to the Turkish metal industry.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Compressor air filter, 10 micron.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Compressor oil filter, 5 micron.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Portable air compressor, 2 horsepower.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Industrial air compressor, 10 horsepower.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Nitrogen is one of the elements that we encounter in every aspect of our lives. It is important to ensure certain controls and separation of nitrogen, which is 78 per cent even in oxygen in the air. Nitrogen or nitrogen generators are used for procedures seen as purification processes. As a result of the use of nitrogen generators in production areas and various factories, efficient and economical use is in question. Due to the importance of nitrogen generator, it is found in many brands and types. However, the first brand and product that comes to mind when it comes to nitrogen generator is Nitroxtec nitrogen generator. Its high-end features and more successful results compared to other devices cause the machine to stand out. It is designed to provide maximum performance and uninterrupted nitrogen production. It is produced with superior technology. It works with PSA (Pressure Swing Adsorption) process.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

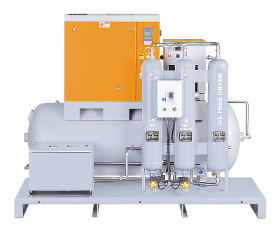

Use 18 Bar Dry Air systems for laser cutting benches. Get rid of your nitrogen gas costs for cutting. Very high costs are paid for quality cutting in laser machines. With the 18 Bar Dry air system, you can get rid of tube and transportation costs. With the 18 Bar Dry air system, you can put an end to your tube purchase costs. With the oil-free pneumatic Booster, oil-free and dryness can be guaranteed in the cutting air. Thanks to the Activated Carbon Towers and Chemical Dryers used in the system, continuous measurement is made and provides dry and oil-free air flow.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Discover Oxygen gas production with Nitroplace’s superior quality and modern technology. PSA technology is applied in the separation of oxygen gas from compressed air. Thanks to PSA technology, you can produce oxygen gas in the range of 90% – 95% purity at a capacity of 0.5 – 385 Nm3 / h. Please contact us for our alternative products that are less costly, safe and suitable for your needs. Why don’t you produce oxygen on-site with low costs instead of buying oxygen cylinders yourself? Nitroxtec; oxygen generators have the modern technology needed to produce oxygen. Our Oxygen Generators is reliable, sustainable and cost-effective source of oxygen gas with modern PSA technology. Our oxygen generators are used in every sector where oxygen gas is needed. It is a very important option for companies that value sustainability, efficiency and profitability. Nitroxtec; It enables you to become a professional oxygen producer with on-site oxygen generators. Produce the oxygen gas yourself.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Advantages of Container Type Nitrogen Production Systems Flexibility: Container-type nitrogen (nitrogen) production systems can be adapted to different production capacities and purity levels. In this way, they can offer the solution that best suits the needs of businesses. Easy installation: Container type nitrogen (nitrogen) production systems are delivered ready for use. In this way, businesses do not need special expertise for installation. Portability: Since container type nitrogen (nitrogen) production systems are portable, they can be easily moved to different locations according to the needs of the businesses. Container type nitrogen production systems are one of the most preferred nitrogen production systems with their fl exibility and simple installation that meets the needs. Container type nitrogen production systems are a perfect solution for businesses, thanks to their portable and ready-to-use features.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Deoxy Nitrogen purification units are devices used to separate nitrogen in the air from oxygen, carbon dioxide and other gases. The purification process is done by taking advantage of the differences between the molecular sizes and physical properties of the gases in the air. In the catalyst unit, palladium-coated alumina binds externally introduced hydrogen gas atoms. The remaining (1,000 ppm) oxygen gas molecules in the 99.9 purity nitrogen gas produced in the PSA generator combine with hydrogen gas on palladium alumina and turn into water, thus raising the nitrogen gas to an ultra-pure level. The water in ultra-pure nitrogen gas is dried with the help of a special desiccant dryer, and ultra-high purity 99.9999 (1ppm O2) nitrogen gas, purified from oxygen and moisture, is transferred to the systems. A special automation system is used to ensure the most efficient and minimal consumption of hydrogen gas used in the catalys.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Container Type Oxygen Production Solutions Oxygen is an indispensable gas for human life. It is widely used in medical, industrial and many other fields. Container type oxygen production systems for oxygen production are one of the most preferred solutions for businesses. Advantages of Container Type Oxygen Production Systems Flexibility: Container-type oxygen production systems can be adapted to different capacities and needs. In this way, it offers the most suitable solution for the needs of businesses. Easy installation: Container type oxygen production systems are very easy to install. In this way, it allows businesses to start producing oxygen in a short time. Portability: Container type oxygen production systems are portable. In this way, it can be moved to different points according to the needs of the businesses.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

It enables you to reach bright, clean, burr-free and perfect cutting quality in laser cutting. Nitroxtec laser cutting system has been produced by paying attention to the thickness, type, cutting time and laser technology of the metal being cut.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

With professional and modern technology, High Pressure Desiccant Air Dryers with a capacity of up to 300 bar can be produced according to the needs of your production facility. Compressed air may contain various undesirable contaminants such as water vapor, oil, particles and dust. If polluted air comes into contact with equipment in the production process, it causes equipment damage. Features of High Pressure 50Bar Desiccant Air Dryers Standard Accessories: It has electronic control feature. Long-life pneumatic valves of European origin Superior performance active alumina American and Japanese made exhaust air silencers Inlet and outlet air filters Zero air loss water discharge system at the entrance Optional accessories: Dewpoint sensor and Energy saving mode Maximum Working Pressure: 50Bar-300Bar varies depending on the models. Regeneration air loss rates: -40 Dewpoint: 2.7% -70 Dewpoint: 5.4% Our High Pressure Desiccant air dryer models have a 2% air loss rate.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

LWCand Pancake coiled copper tube which is named for its coiled style, is widely used on the connecting for the separated air-condition. On the other hand it is used in water distribution systems, chilled water mains, drainage and vent systems, heating systems (includingsolar), fuel-oil systems, oxygen systems also in non-flammable medical-gas systems. They are produced by horizantal casting after annealed tubes are drawing, to be copper tubes. They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CA 603 Single Corner Cleaning Machines are used for striping of bottom and top surfaces and cleaning outer corners of 90° PVC cleaning profiles. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps Stops automatically after stripping and cleaning operation PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Pneumatic tool fixing and releasing system Stripping blade levels are adjustable according to laminated and un laminated profiles Processing capability of 2 different PVC profile 4 different cutter set can be mounted on a modul (CA 603) STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200Wx 2~3 400V AC 50-60 Hz. 3000 D/dak RPM

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION After welding clean up down and corner sides of 90º PVC Profiles after welding. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Stripping blade levels are adjustable according to laminated and un laminated profiles Pneumatic tool fixing and releasing system Single or multi cleaning operations can be processed Automatic start up feature when profile placed on the table Stops automatically after stripping and cleaning operation STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200 Wx3 400V AC 50~60 Hz 3000 D/dak RPM D: 215 d: 32 mm. 36 Lt/dak. 6~8 Bar 92x 101x 143 cm 249 kg. 198 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CK 412 is an automatic saw blade machine which is ideal for cutting operations of the PVC glazing beads at 45°. Adjustable saw blade feeding speed Pneumatic saw feed by pushing button Equipped with 2x pneumatic vertical clamps Automatic return to start point of the process Twin blade design 8 glazing beads can be cut simultaneously using single mold without problems STANDARD ACCESSORIES 1x Ø 200 and 1x Ø 103 mm saw blades KN 152 roller conveyor Air gun OPTIONAL ACCESSORIES Clamping device for special glazing beads Additional saw blades Digital Roller Conveyor with Automatic Stop (SKN 301) SKN 300, SKN 450,SKN 600 conveyor SKN 301, SKN 451, SKN 601 conveyor Videolar TECHNICAL SPECIFICATIONS 1200 W x2 400V AC 50~60 Hz 3.000 D/dak. RPM D1:103 mm D2:200 mm d:30-32 mm 6~8 Bar 35 Lt. / dak. 54x113x124 cm 168 kg 134 kg

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 700 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 700 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard Safety locking switches on top guard and front doors Double acting clamps for operator safety STANDARD ACCESSORIES • Equipped with saw blade Ø 700 mm& 4 Kw motor • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 2 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 700 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • Laser marker set for 90 ° of cutting operation TECHNICAL SPECIFICATIONS 4kW - 3P 400 V 50~60 Hz

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 550 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 550 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard STANDARD ACCESSORIES • Equipped with saw blade Ø 550 mm • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 1 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 550 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • 1 x horizontal clamps • Laser marker set for 90 ° of cutting operation Videolar TECHNICAL SPECIFICATIONS 4kW - 3P 50~60 Hz 400 V 2400 D/Dak. RPM D: 550 mm d:30 mm 6~8 Bar 160 Lt/dak. 106x131x156 cm 419 kg 373 kg

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 S is designed for the strait or angular cutting operations of the large size of profiles made of aluminum and PVC materials by means of Ø 420 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCESSORIES • Equipped with saw blade Ø 420 mm • MKN 301 roller conveyor (3 m) • 2 x vertical clamps • Spray saw blade lubrication system (ACK 420S) • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 420 mm • 2x horizontal clamp • VCE 1570 Chip vacuum extractor • DKN 300-450-600 conveyor • SKN 300-450-600 conveyor • Laser marker set for 90 ° of cutting operation • Pneumatically working top guard Videolar TECHNICAL SPECIFICATIONS 2.2kW 50/60Hz

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminum materials by means of Ø 420 mm of saw blade. HDL 300 It is computerized heavy duty lenghtstop which helps to cut the profiles precisely in the required measurements. ACK 420 General Features Two-hand safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0°, both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCSSORIES Equipped with saw blade Ø 420 mm Manuel MKN 300 end-stops (3 m) 2 x vertical clamps Spray saw blade lubrication system (ACK 420S) Air gun OPTIONAL ACCESSORIES Laser marker set for 90° of cutting operation Pneumatically working top guard Additional saw blade Ø 420 mm 2x horizontal clamp

Request for a quoteResults for

Air accessories - Import exportNumber of results

28 ProductsCountries

Company type