- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turbine blades

Results for

Turbine blades - Import export

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The most popular and effective way for the Coanda Screen, also called hydropower screen, is using it for the Hydroelectric Plants – Hydropower energy. Coanda Water Screen prevents harmful materials, sediment in the intake process, and provides clean water. Thus, turbine blades in hydropower plants can operate for longer without being damaged. Thus, the Coanda Intake Screen operates long years with negligible maintenance and with no moving parts. Main advantages of Coanda Effect Screen in hydropower plants: - Sustainable energy production and increased output efficiency - Self-cleaning and no power requirement - Increased income with continuous water intake - Durable protection bars and negligible maintenance - Specialised design for high water intaking performance - Protection of turbine blades from abrasion, sediment and debris We are able to improve your electric generation efficiency with our high capacity Coanda Sieb Screen.

Request for a quote

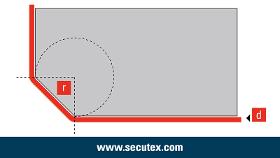

SPANSET SECUTEX GMBH

Germany

In addition to loads with rightangled edges, there are also transportable goods with different geometry. These include loads with projecting spines and with sharp or jagged external contours such as gearwheels, turbine blades, etc. These edges are not addressable using normal approaches. The secuwave protective sleeve was developed for components with extremely critical edges. secuwave increases the deflection radius. The „sharp edge“ has no contact with the protective sleeve and thus cannot cut it.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride ceramid textile guides shoes is high wear resisting than zirconia and alumina, it will be more widely use in the textile industry in future. Silicon nitride has better high temperature capabilities than most metals combining retention of high strength and creep resistance with oxidation resistance. In addition, its low thermal expansion coefficient gives good thermal shock resistance compared with most ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity Typical Silicon Nitride Uses: .Rotating bearing balls and rollers .Cutting tools .Engine moving parts - valves, turbocharger rotors .Engine wear parts - cam followers, tappet shims .Turbine blades, vanes, buckets .Metal tube forming rolls and dies .Precision shafts and axles in high wear environments .Weld positioners

Request for a quote

NEW WORLD WIND

France

The Aeroleaf ® is a patented micro wind turbine composed of a double blade with a vertical axis in a shape of a leaf and a synchronous microgenerator with permanent magnets. Driven in rotation by the blade, without belts or gears, the magnets pass in front of the coils and thus generate an alternating current. This is immediately rectified in direct current to be able to sum the currents. The Aeroleaf have an aerodynamic profile optimized to exploit the weakest winds (from 2.5 m/s of wind) as well as the strongest (up to 43 m/s continuously, 50 m/s in gusts).

Request for a quote

INOXYDA SA

France

We cast KAPLAN blades and impellers in aluminium bronze. With 15 000 To melting capacity and 5 mx5 m casting capabilities we can accommodate all projects.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The Rocking Mixer is a gentle mixing system. The bucket is fitted with mixing turbine blades. During rotation, the machine also oscillates back and forth, achieving both a diffusion and motion-blending effect. The rocking mixer has the advantages of maintaining the integrity of materials, which means that the materials are not easily broken inside the drum, the mixing time is short and the result is a high uniformity. The rocking mixer is easy to maintain. It is suitable for materials such as medicinal or seasoning powder. A combined semi-automatic feeding system is optional.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Collett Consulting route access surveys take into account horizontal and vertical alignments, weight and dimensional issues across all types of roads, structures and environments. Used extensively for heavy transport, abnormal loads and wind turbine components, Collett Consulting's detailed route access surveys provide in-depth route analysis to identify the most suitable delivery path. Our route access surveys provide an outlined analysis of how your project, cargo or components will be delivered to their destination. With wind turbine blades increasing in size and the development of new equipment to facilitate heavy transport, it's imperative that delivery routes from port to pad site are surveyed in their entirety for any restrictions that could impact on delivery.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Established in 1928 Collett & Sons has expanded and diversified to become one of the UK's leading industry figures in the world of transport and logistics. Our years of experience coupled with our comprehensive fleet of specialist equipment allows us to expertly undertake all transport projects, no matter how big or small, heavy or light. Our Transport services can facilitate all cargoes from General Haulage and Heavy Transport to Heavy Lift, Crane Vehicles and the complete Project Management of abnormal loads utilising our fleet of over 200 articulated tractor units, crane vehicles, and SPMTs (Self Propelled Modular Transporters). Our continual investment in our fleet ensures that we have the best equipment to facilitate the transport of any cargo, from Super Wing Carriers specifically designed for the transport of wind turbine blades, through to specialist hydraulic Jacking & Skidding equipment.

Request for a quote

SPARES IN MOTION

Netherlands

Complete wind turbine blades and blade sets available for various wind turbine types and brands.

Request for a quote

SPARES IN MOTION

Netherlands

Cleaning your wind turbines may proof to earn you money back real quick.

Request for a quote

SPARES IN MOTION

Netherlands

Damaged blades can cost you a lot of productivity. Have your wind turbine blades services and repaired by specialist wind turbine blade service companies

Request for a quote

SPARES IN MOTION

Netherlands

Take care of your wind turbine blades and inspect them periodically.

Request for a quote

SPARES IN MOTION

Netherlands

Complete wind turbine blades and blade sets available for various wind turbine types and brands.

Request for a quote

SPARES IN MOTION

Netherlands

Siemens wind turbines for sale You will find used and new Siemens wind turbines for sale on Spares in Motion, the supply and demand e-platform for the wind turbine aftermarket. Get an overview of current turbine models for sale or submit a search request, if the wind turbine of your choice is not listed. Our Siemens wind turbines for sale range from: - 1.5 MW – 3.0 MW - in new, used, repaired or serviceable condition - immediately available Siemens spare parts Clicking Siemens turbine parts on Spares in Motion provides you with a vast range of cost-effective spare parts, components and supplies for Siemens on- and offshore wind turbines. From Siemens innovative blades and generators, through to electrical, mechanical or hydraulic spare parts. Shipped to your area within 24 hours,

Request for a quote

SPARES IN MOTION

Netherlands

Special tooling to hoist your wind turbine gearbox, wind turbine blades or complete nacelle.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

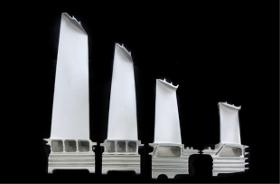

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

TURBOWORKS LTD

United Kingdom

During the turbo rebuilds, we offer an opportunity to enhance both reliability and performance through turbo upgrades. Our array of turbo upgrades encompasses options such as billet wheels, high-performance bearings and seals, larger turbines, ball-bearing conversions, precision machining of turbocharger housings, turbine blade optimization, meticulous porting and polishing, staggered seals, innovative hybrid solutions, and beyond. It's noteworthy that all of our upgraded turbochargers are furnished with enhanced bearings and seals as a standard feature, and all of this is offered at highly competitive prices.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

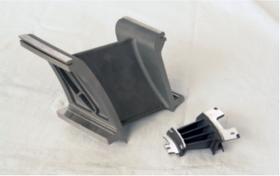

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results. APPLICATIONS: Orthopedic implants (medical engineering) Turbine blades (for airplanes as well stationary turbines) Precision components, for example, for pumps and compressors Work pieces made from tungsten carbide and other hard metals Fan wheels for turbo chargers (automotive industry) Sintered components, etc.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The slewing bearing, also known as slew(ing) ring, is a type of bearing for low-speed and high axial load applications. The slewing bearing is a mechanical component that is used in major industrial sectors. Harbor and deck cranes are one of the ideal applications for using slewing bearings – for example, for container handling. Additionally, for wind turbine blades, the use of slewing bearings ensures the highest level of reliability and efficiency, as required by this sector. APPLICATIONS: Earth Moving Machinery Concrete pumps Civil and Harbor Cranes Wind Turbines Radar Robotics Packaging Logistics Material handling Bottling / filling carousels Rotating tables Polyurethane Injection Systems Drilling Rigs Welding Plants Water Treatment Plants Lunapark Woodworking Machines Marble Cutting Machines Palletizers Aerial Platforms Roller Conveyors / Idle Rollers

Request for a quote

ING. BÜRO RAUSCHENBACH

Germany

Our highly flexible SYSTEM aer 1.1 provides fast and safe access for rotor blade maintenance on turbines with a distance tower to tower tip of up to 18.5 m. Functions such as swivelling and transverse movement of the workspace create added value that is reflected in the quality of rotor blade repairs and costenefficiency. In addition, hinged aisles ensure safe working when catching the blade. The geometry of the self-adjusting suspension allows maximum maintenance height up to the blade root. Wind turbines type class V90 to V162 max. blade tip distance 18.5 m Max. wind speed 14 m/s Rotor blade dimensions of 5.30 m x 3.00 m payload of 400 kg Details of the manufacturer at : https://wpsystems.de/system-aer

Request for a quoteResults for

Turbine blades - Import exportNumber of results

30 ProductsCountries

Category

- Machine tools, metal machining - parts and accessories (6)

- Gas and oil - exploitation (2)

- Transport - heavy loads (2)

- Adjustment - machine tools (1)

- Bearings - ball, needle and roller (1)

- Ceramics, industrial (1)

- Construction - Machines & Equipment (1)

- Energy - renewable (1)

- Filtering equipment and supplies (1)

- Foods, precooked and gourmet (1)

- Gas turbines (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Spare parts for cars (1)

- Steam turbines (1)

- Straps, woven - industrial (1)

- Turbines (1)

- Windmills (1)