- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tunnelling machines

Results for

Tunnelling machines - Import export

AEROLIFT INDUSTRIALS B.V.

Netherlands

The complete lifting solution we designed for inside a tunnel boring machine (TBM) consists of two vacuum lifters. The first vacuum lifter transports the tunnel segments and keystones to the segment feeder of the erector. To meet the erector’s position the suction pad is able to rotate 90 degrees during the transport. Vacuum lifter as part of the erector The second vacuum lifter operates as part of the erector and perfectly matches the interface of the TBM. To meet every required position the lifter is able to turn 360 degrees.

Request for a quote

FERPLAST SNC

Italy

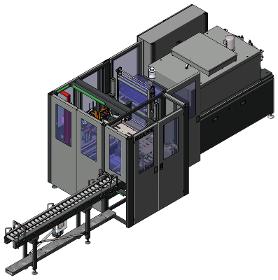

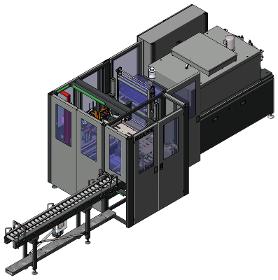

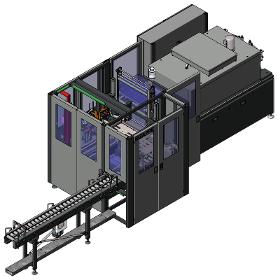

PRATIKA 55 SMART: AUTOMATIC THERMORETRAIBLE PACKAGING MACHINE WITH INCORPORATED TUNNEL The new model of automatic shrink-wrapping machine Pratika 55 Smart comes from a careful attention to the needs, with the aim of offering a technologically advanced but flexible and extremely compact product. The included tunnel, revolutionary in the world of automatic machines, responds to the needs of space, but above all to reduce the labor costs to a minimum, thanks to the patented "come back" option to a single operator. Enhanced by a strong mechanical and electronic technological content, the new Pratika 55 Smart represents a perfect synthesis of reliability, versatility and safety, which once again evolves the way to conceive the compact automatic operation shrinkwrappers.

Request for a quote

FERPLAST SNC

Italy

The shrink tunnel, equipped with temperature adjustments, height and speed, is incorporated in order to make the machine compact and versatile, suitable for series production. The welding time is electronically set and the absence of fumes is ensured by teflon-coated blades. The sealing bar motorized, equipped with security system, the closed circuit cooling plant and motorized scrap-winder, are part of the standard equipment of the machine. FEATURES Digital panel with 6 programs Descent sealing bar manual or automatic Discharge conveyor for product Legs with locking wheels Only welding and welding + retraction Sealing bars with closed-circuit cooling system and patented safety system Emergency switch Teflon coated sealing bars Electromechanical automats Welding speed automatic controller Motorized conveyor belt with adjustable height Motorized scrap-winder Air flow shrink tunnel swiveling Adjustable temperature with electronic temperature controller

Request for a quote

FERPLAST SNC

Italy

TF 6540 FA SHRINK WRAPPER MACHINE WITH PNEUMATIC PUSHER TF 6540 FA semiautomatic sleeve sealing machine with pneumatic pusher suitable for shrink packing both single object and combined. Shrink packing machine is used in many industrial sectors such as printing, pharmacy, floor, beverage, beer etc. and it’s suitable for all kinds of shrink films such as PVC, POF, PP, PE etc The machine is equipped with motorized reel holder and stabilizer plate for light parcels. After the process of sealing & cutting, the products enter the shrink tunnel BS 5540 M automatically.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

BURRE HYDRAULIK GMBH

Germany

tunnel drilling machine, bridges, houses

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 33 x 38 cm age 1998 die cutting machine tunnel die cutting machine 5 clamp arms counter pressure GD specially for inmould labels max. diameter for round shapes 365 mm max. 9 cycles / min (offload - without GD) Ref: BU230110T Please ask for price. We ship and install worldwide!

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

THOMSON MACHINERY BV

Netherlands

D7 is a tunnel car washing machine with 7 washing brushes, which is the economic version of D9. This tunnel type of equipment can wash cars quickly and continuously, and it can wash 50-60 cars per hour. Its production greatly meets the needs of customers with large business sites and a large amount of car washing. Now many customers with a daily car washing volume of more than 500 cars are using this equipment. This tunnel type of equipment is sturdy and durable. Its appearance takes into account the likes of domestic and foreign customers. It covers a relatively small area, has strong adaptability to the site, and has excellent performance. It is favored by some customers who are limited by the site and want to install tunnel machines.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling, sealing and capping machine for viscous products Capacity of the machine: 60 cycles/min. max. 3.600 jars/h Special features: Dosing pump with motorised Adjustment from 0 – 500 ml Heatable hopper with agitatork Output of the filled jars to the cooling tunnel and return to machine for sealing and capping Heatable filling nozzle with recovery system (drip-free) Foil lay-on station (from foil magazines or with punching tool) Sealing station (conduktive system or induction sealing) Capping station

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Handling tunnel segments by vacuum technology. Aerolift designs customised lifting solutions for the complete handling process of precast tunnel segments. The lifting solutions are used during production, transhipment and in the tunnel boring machine (TBM). The unique features of vacuum handling are highly suitable to handle concrete products, such as tunnel segments. Why choose vacuum handling Specially for concrete products, vacuum offers many interesting advantages compared to other lifting methods: Demoulding after 8 to 10 hours Demoulding, lifting, and turning by one lifting device Efficient during handling and the use of storage space No damage or deformation to the tunnel segment Less chance of cracks in the concrete Easy and fast handling Reuse of the same mould Reduced chance of accidents, because no one has to be near the load before, during or after handling Very safe due to the high safety standards of vacuum handling Handling tunnel segments during production

Request for a quote

KITTNER ANLAGEN - UND MASCHINENBAU

Bulgaria

The machine is designed for cleaning, degreasing, chemical treatment of the outer layer and blowing of small components. The parts are arranged in trays with dimensions 600x400x70-150 mm. Two washing zones – pre-washing zone and zone for main washing. After each washing zone there is zone for blowing. The pre-washing zone has an external band filter, which is with the possibility of processing a high volume of washing solution and captures particles of a size greater than 350 μm. The band filter cleaning the washing solution of oil and hard dirt. The mainly washing zone has a column bag filter, which captures particles of a size greater than 50 μm. Both filters have monitoring systems for the degree of soiling and in case of clogging the machine stops. Automatic dosing of the cleaning agent. Machine corpus made entirely out of stainless steel, material No. 1.4301. The machine complies with the high CE-Requirements and EU- and USDA regulations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACEMAL NV

Belgium

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

ACEMAL NV

Belgium

These products are baked through an entirely automated tunnel type oven. Production machines: From 3500 waffles per hour.

Request for a quote

HIDROMEC SRL

Italy

Mobile hydraulics applications cover a very wide range of mobile machines working in all kinds of environments, often under difficult operating conditions (operating outdoors, at the mercy of the weather) and in very dirty environments (grease and grease mixed with dust). Whether it is a mobile crane lifting heavy loads, a construction machine, a tunnel boring machine or a demolition tong, they all have very high requirements for functionality and durability. Often, a robust design for the durable use of the machine must be combined with a simultaneous reduction in weight. In all modern equipment, it is necessary to find sealing solutions that offer high static and dynamic sealing performance, low friction and suitable system guidance. HIDROMEC develops sealing systems for mobile equipment that are reliable, durable and comply with environmental standards.

Request for a quote

PLASMA COMPANY LLC

Ukraine

Mining machinery and equipment is mainly used for mining operations. But, at present, it is widely used not only in the mining industry but also in such industries as metallurgy, mechanical engineering, energy, chemical industry, etc. If we talk about the classification of mining equipment, it is divided into mine, quarry, mineral processing, and transport equipment. A list of the equipment used in the mining and mineral processing industry is extremely large, it is boring machines, machines, and systems for underground mining; mining systems and automatics; mining machines and systems for open mining operations; jetting means mining operations; transport machines; machine mine water, ventilation and compressed air systems; machine mine hoist and others. We manufacture: Electric Pulling Winches Electric Scraper Winches Bottom Dump Muck Cars Rocker Dump Muck Cars Air Mucking Machines Electric Mucking Machines

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply various types of EPS-XPS sheet and bale packaging machines, including wrapping machines and shrink tunnel packaging machines.

Request for a quote

PKO-SURA COMPANY

Russia

The Sura MK and Sura AMK candy forming machines are designed for forming endless bundles, as well as candy cases with and without filling of various shapes in cross-section: rectangular; trapezoidal; semicircular; round, etc. The Sura MK machine is equipped with a guillotine cutting unit, a conveyor and can be connected to glazing machines and cooling tunnels; The Sura AMK machine is used with cooling tunnels and deposits bundles or candy cases on the tunnel tape. For the production of candy cases, the Sura AMK machine is equipped with a string cutting unit.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Parts are cleaned, rust removed, rinsed, phosphatized and dryed in conveyor bent tunnel w ashing machines, all these applications are nonmanuel. When the parts are moved into the machine, they exposed all these operations and moved out. These conveyor bants are 304 or 316 quality stanless steel components. Speed of the conveyor is controlled digitally. Circulation pumps are very good degisned parts. Heating system can be optianlly electric, cell cored or burneroperated. Isolation is very sensitively handled for the energy saving. PLC containing systems can be controlled from operation panel. Our all machines contain automatic water feeding and liquid level control systems.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Mining equipment is continually subjected to tortuous conditions that punish hydraulic cylinders. These gruelling conditions include dust, grit, heat, cold and moisture. In addition, the equipment is subject to slamming loads and mechanical impacts. Gidrolast designs and manufactures heavy-duty hydraulic cylinders that endure these very difficult conditions. Gidrolast cylinders can be found on hydraulic equipment in surface and sub-surface mining operations all around the globe. They are installed on dredgers, hydraulic shovels, dump trucks, oversized off-road equipment, tunnel boring machines, ore haulers, ore crushers and aggregate conveyors, to name but a few. We manufacture both rod cylinders and telescopic cylinders, double and single action, in sizes from 12mm (1/2″) up to 700mm (28″) bore. Call us to find out why mining equipment OEM’s around the world depend on Gidrolast cylinders.

Request for a quote

GEYSER LLC

Russia

The most efficient model of washing equipment designed for continuous processing of parts. It may include washing, rinsing and drying units. The washing unit is equipped with a conveyor, a control cabinet, an assembly compartment, an oil separator, tubular electric heating element, a temperature sensor and a solution level meter. The conveyor speed is individually adjustable and can reach several meters per minute. The unit is designed for surface treatment by high pressure water jets to remove oil and grease contaminants, fine chip, cooling mixtures, and coked-free sand and dust deposition. The installation fully meets modern requirements applicable to the parts, components and assemblies washing technology. The unit is intended for indoor use.

Request for a quote

GLOBAL TRADING CO.

Turkey

X-Ray Baggage Scanning Machines Tunnel Sizes from 5030 to 10080 (Stock)/ 100100 to 180180 in order, Metal Detector Doors for all purposes (Stock), HandHeld Detector (Stock), Access Control equipment and system (Stock Depend on order), X-Ray Body scanner, X-Ray Automobile/ Truck/ Trailer Scanner.

Request for a quote

UTF

Ukraine

Capacity: 300-1200 kg/h Quantity of dough layers: 8-16 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - proofing of product at proofing chamber for improving quality of products - replaceable drums of forming machine for different kinds and sizes of product - options for additional equipment: automatic dough feeding system into extruder salt sprinkler at the oven entry oil sprinkling on the exit form the oven stackers for staking products in stacks - design of lines can be developed according to customer production premises Equipment set of the line: - dough kneading device - proofing chamber - feeding conveyor - extruder - laminator - three-modular rolling machine - forming machine - tunnel oven - rotary conveyor - cooling conveyor - stacker

Request for a quoteResults for

Tunnelling machines - Import exportNumber of results

31 ProductsCountries

Company type

Category

- Food Industry - Machines & Equipment (3)

- Industrial washing facilities (3)

- Packing and packaging - machinery and equipment (3)

- Wrapping machines (3)

- Confectionery - machinery and equipment (2)

- Cleaning machines, industrial (1)

- Concrete constructions (1)

- Cylinders, hydraulic (1)

- Finishing and binding - machinery and equipment (1)

- Hydraulic equipment (1)

- Lifting equipment (1)

- Mining and quarrying - machinery and equipment (1)

- Mining services (1)

- Plastics - machines and material for industry (1)

- Rolling mills - machinery and installations (1)

- Sandblasting equipment (1)

- Scouring - steels and materials (1)

- Security - Services (1)

- Silicones (1)

- Surface treatment - machinery and equipment (1)