- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tungsten electrodes

Results for

Tungsten electrodes - Import export

PLANSEE SE

Austria

Tungsten and tungsten alloy electrodes are used to produce the arc in high-intensity discharge lamps. Tungsten electrodes from Plansee excel due to their outstanding physical and mechanical properties: a high melting point, low vapor pressure, low thermal expansion, good thermal conductivity and a low electron work function. Plansee supplies anodes, cathodes and support rods. With special alloy additives, Plansee improves the high-temperature dimensional stability, electron work function, formability, machinability and thermal conductivity of the material. For cathodes, aluminium-potassium silicate (AKS) or lanthanum oxide-doped tungsten is available. A new addition to the range: WLZ, a tungsten material doped with lanthanum and zirconium oxide. WLZ is the non-radioactive alternative to thorium-doped materials.

Request for a quote

CMPLAST

Poland

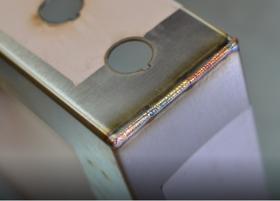

Our company's offer includes welding of steel structures made of stainless steel and carbon steel. Welding is carried out using the method MIG / MAG creation of an electric arc between the head and the material. It is covered with shields of mechanical gases such as, for example, neutral (argon) or chemically active (carbon dioxide); TIG welding using a tungsten electrode and a shield of noble (inert) gas, most often argon. We combine elements of standard size as well as largesize items We provide welds with the highest usable parameters, but after the welding process, the combined elements are additionally grinded and we remove any sharp edges or endings

Request for a quote

BASAK LAZER

Turkey

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Welding” is a manufacturing or carving process that joins materials, usually metals or thermoplastics, using high heat to fuse parts and allow them to cool. The difference between welding and lower-temperature metal joining techniques, such as soldering and brazing, is that welding does not melt the base metal. Thanks to the modern equipment that we have on offer, we can perform, among other things, professional welding of carbon steel, aluminium and other metals using the MAG method and the MIG method. Thanks to experienced specialists working for us, the obtained effect is of very high quality and does not contain harmful contaminants on the ponds. We can also connect structural or stainless steel with the TIG method, using special tungsten electrodes. Welding structures with this technique are very popular because it allows for a very high quality of obtained connections and there are no restrictions on the position in which the connection is made.

Request for a quote

PLANSEE SE

Austria

EDM Electrodes made of the tungsten alloy SPARKAL are available as tubes, rods, square rods and plates in different dimensions in the Plansee Online Shop. Order fast and easily from the producer's online shop: www.plansee.com/shop.

Request for a quote

PLANSEE SE

Austria

The following nozzles and electrodes made of tungsten-copper are available from stock: Nozzles: — PN-F4-6 — PN-F1-6 — PN-G-W / PN-GH-W Electrodes: — PE-F4 — PE-F1-45 / PE-F1-90 — PE-3M63 / PE-7M63 / PE-9M63 Thanks to its high melting point, tungsten ensures that even the high temperatures that occur at the particularly exposed tip cause no damage to the spray nozzle. The high level of thermal conductivity provided by tungsten and copper ensure optimum heat dissipation. As a result, our nozzles and electrodes offer excellent resistance to arc erosion. This guarantees a long service life. — outstanding arc erosion resistance — high temperature resistance — optimum thermal conductivity

Request for a quote

PLANSEE SE

Austria

Welding electrodes made of tungsten, molybdenum and their alloys are particularly suitable for welding highly conductive materials such as copper. They are used in the following processes: Spot welding, Roller welding, Projection welding, Upset welding. Welding electrodes made from our refractory metals and their alloys have a relatively high level of electrical conductivity while also exhibiting outstanding stability at high temperatures. They therefore have a considerably longer service life than conventional materials such as copper and copper alloys.

Request for a quote

VOSSE SP. Z O.O.

Poland

Metal welding is, the process of welding metals together, performed using heat, superheating or using a welding agent. Each of the above-mentioned solutions is distinguished by different properties, allowing to combine different types of materials and also to apply welding in a specific, well-defined area. We offer our customers comprehensive services in this area with the highest international standards. At our facility, we weld using MAG and TIG methods, in accordance with the international standards set forth in EN ISO 3834-2 for welding metal materials and EN ISO 1090-2. We weld both black and stainless steel. We manufacture structures up to EXC3 class. We have more than 70 WPQR welding qualifications according to EN ISO 15614. Our welders are qualified to weld by methods: MAG 135 - Arc welding with solid wire in active gas shielding. MAG 136 - Arc welding with powdered wire in active gas shielding. TIG 141 - Welding with non-fusible tungsten electrode in an inert gas shield.

Request for a quote

ORBITEC GMBH

Germany

The RBK 60 S is an extremely robust water-cooled weld head for a standard heat exchanger application up to an ID of 60 mm, modified to an ID of 99 mm or 120 mm. The head is pneumatically centred and is available with a rotating wire device and/ or arc voltage control (AVC) as an option. The head can also be used with a pneumatic positioner instead of a balancer. Versions: — RBK 60 S weld head with pneumatic centring, including hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring and wire feeder incl. hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring, wire feeder and AVC incl. hose package, 8m, water-cooled Package includes: — Weld head — Small torch incl. torch consumables and tungsten electrode Ø 2.4 mm — Water-cooled hose package, 8 m — Pull bar B — Transport case Optional: — Div. spring sleeves and pull bar sets for RBK 60 S — Torches, Balancer, Tube-to-tubesheet positioner...

Request for a quote

MR CO. LTD.

Ukraine

Argon welding is a popular name among people for welding technology, in which welding is performed in a shielding gas environment, most often argon. The gas prevents the metal under welding from coming into contact with the oxygen in the air, preventing oxidation. Inert argon is well suited for this purpose as it is non-toxic and relatively inexpensive. The equipment for argon welding comes in two types, TIG and MIG. In both cases, the machines are equipped with a non-consumable tungsten electrode. The difference is that TIG uses separate hard facing rods, but in MIG, the wire is fed automatically from the spool, for which people often call this method semi-automatic.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Support tungsten / electrode size: Ø1.0 ~ 4.8 mm 2. Grinding angles from 10° ~ 60° 3. Tungsten grinder is easy set up 4. No equipment changes required 5. Electrode notching station for simple cut off available 6. Safety 7. Good welding quality 8. Increase welding productivity *CE Conformity

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Tungsten bars, sheets profiles und defferent alloys

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Tungsten copper electrode for EDM applications

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

ALXR LIMITED

United Kingdom

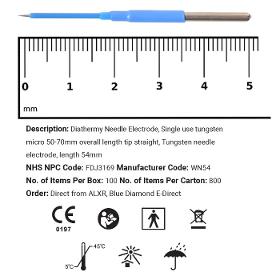

NHS NPC Code: FDJ3281 Manufacturer Code: WN54-W No. of Items Per Carton: 800 Diathermy pencils, electrode attachments, cautery pens, tip cleaners, X-ray scratch pads, polishers and other associated accessories. Diathermy pencils are used during surgical procedures to cut tissue and produce coagulation via electro-surgery. 1.1.Electrosurgery pencil 1.2.Electrosurgical handpiece 1.3.Electrosurgical device 1.4.Bipolar electrosurgery pencil 1.5.Monopolar electrosurgery pencil 1.6.Surgical cautery pencil 1.7.High-frequency surgical pencil2.1.Diathermy probes 2.2.Electrosurgical electrodes 2.3.Radiofrequency electrodes 2.4.Monopolar electrodes 2.5.Bipolar electrodes 2.6.Surgical cautery electrodes 2.7.Electrosurgical instruments3.1.Grounding pads 3.2.Electrodes for grounding 3.3.Return electrodes 3.4.Neutral electrodes 3.5.Patient grounding pads 3.6.Dispersive electrodes 3.7.Electrodes for electrosurgery

Request for a quote

ALXR LIMITED

United Kingdom

NHS NPC Code: FDJ3169 Manufacturer Code: WN54 No. of Items Per Carton: 800 We provide quality diathermy pencils, electrode attachments, cautery pens, tip cleaners, X-ray scratch pads, polishers and other associated accessories. Diathermy pencils are used during surgical procedures to cut tissue and produce coagulation via electro-surgery. The electrode attachments are used in conjunction with the diathermy pencils. Associated accessories can also be used in conjunction with both pencils and electrode attachments. To provide surgeons with a more traditional feel, these pencils feature tactile buttons, less memory in the cords, and high-quality plugs. Several sterile pencil options are available in push-button configurations with holsters to help promote safe use. 1.1.Electrosurgery pencil 1.2.Electrosurgical handpiece 1.3.Electrosurgical device 1.4.Bipolar electrosurgery pencil 1.5.Monopolar electrosurgery pencil 1.6.Surgical cautery pencil 1.7.High-frequency surgical pencil2.1.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

• TIG welding: The letters TIG stand for tungsten inert gas welding and generally belong to the inert gas welding process. In this welding process, an arc burns between a tungsten electrode (non-consumable) and the workpiece. The electrode, the arc and the molten bath are protected from the atmosphere by an inert gas. • MIG / MAG welding: The letters MIG stand for metal inert gas, the letters MAG for metal active gas. This welding process is also part of the group of metal inert gas welding processes. In this welding process, a consumable wire electrode is fed continuously. The arc burns between the supplied wire and the workpiece. Throughout the welding process, the arc and the weld pool are protected by either an active gas (MAG process) or an inert gas (MIG process). This welding process can be used for a variety of materials and is also available for a large number of welding consumables.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tungsten electrodes - Import exportNumber of results

18 ProductsCountries

Category

- Welding work - steels and metal (6)

- Foundries - copper, bronze and brass (2)

- Bars - non-ferrous metal (1)

- Disposable medical and surgical articles (1)

- Grinding - machine tools (1)

- Industrial sprayers for surface treatment (1)

- Laser - cutting and welding machines (1)

- Steels and metals - machining (1)

- Steels and metals - welding and brazing (1)

- Surgical apparatus and equipment (1)

- Welding, electric - equipment and supplies (1)

- Welding, soldering and brazing - equipment and supplies (1)