- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tubes- welded

Results for

Tubes- welded - Import export

COLIMET SRL

Italy

Electronic automated arc spray equipment of all metal wires - electronic control and management

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

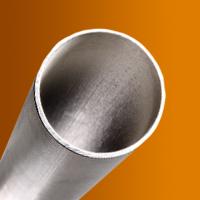

The welding process is one of the core ways in which we manufacture precision tubes. Our high-quality tubing starts off as a flat strip of metal. The strip is formed into a tube through a series of rollers and the join, also called the seam, is then welded together. Welded Processes Special non-destructive testing methods – including eddy current, ultrasonic and pressure testing - are used to ensure a consistent weld. Just like with seamless manufacturing, welded tubes can be drawn down by plug drawing or sinking. This method can be used to create very long lengths of coiled tube, these can also be measured during coiling using a laser measurement. The main welded tube manufacturing processes used are strip welding and cold drawing, but other important processes in between, or at the end of the drawing process, include Please note that we have a minimum order value of £10,000.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube frames, tube bent fittings, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

ORBITEC GMBH

Germany

With tube-to-tubesheet weld heads, it is possible to achieve consistently high-quality, reproducible welding of tubes to tubesheets, with or without additional wire. The tubes to be welded can be flush with the tubesheet, offset, protruding or behind the tubesheet. The RBK 38 S and the RBK 60 S are our two new tube-to-tubesheet weld heads. The RBK 38 S is a small, handy water-cooled head for welding tubes to tubesheets up to an ID of 36.7 mm, without additional wire. Package includes: — Weld head — Water-cooled hose package, 6 m — Pull bar B — Gas hood ID 35 mm — 0° electrode holder — Transport case Optional: — Div. electrode holders for RBK 38 S — Div. gas hoods for RBK 38 S — Div. spring sleeves and pull bar sets for RBK 38 S

Request for a quote

ORBITEC GMBH

Germany

The RBK 60 S is an extremely robust water-cooled weld head for a standard heat exchanger application up to an ID of 60 mm, modified to an ID of 99 mm or 120 mm. The head is pneumatically centred and is available with a rotating wire device and/ or arc voltage control (AVC) as an option. The head can also be used with a pneumatic positioner instead of a balancer. Versions: — RBK 60 S weld head with pneumatic centring, including hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring and wire feeder incl. hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring, wire feeder and AVC incl. hose package, 8m, water-cooled Package includes: — Weld head — Small torch incl. torch consumables and tungsten electrode Ø 2.4 mm — Water-cooled hose package, 8 m — Pull bar B — Transport case Optional: — Div. spring sleeves and pull bar sets for RBK 60 S — Torches, Balancer, Tube-to-tubesheet positioner...

Request for a quote

METAL IN LTD

Bulgaria

Metal In put into operation a machine for laser cutting of pipes with automatic loading and unloading. The size of the treated pipes is: Round pipes: 120 mm Rectangular tubes: 100x100mm The maximum length of the workplace is 6500mm. The machine is equipped with excellent software that allows different shapes in tubes for subsequent assembly and welding. Also, pipes can be cut so that one wall remains uncut, allowing it to bend easily and accurately and find a frame.

Request for a quote

ERATEC

France

Preheating of forging tools Preheating of tubes before welding Preheating before thermal spraying Preheating of moulds

Request for a quote

STAPPERT INTRAMET SA

Belgium

Square tube or rectangular tube, welded, grade 1.4301, 20-10-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Square tube or rectangular tube, welded, grade 1.4301, 15-15-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Square tube or rectangular tube, welded, grade 1.4301, 10-10-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Square tube or rectangular tube, welded, ground grit 400, grade 1.4301, 20-10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Square tube or rectangular tube, welded, ground grit 240, grade 1.4301, 15-15-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 12-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed ground grit 240, grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAPPERT INTRAMET SA

Belgium

Triangular tube welded, grade 1.4307,. 40-40-40-2.5

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

STAPPERT INTRAMET SA

Belgium

Triangular tube welded, grade 1.4301,. 40-40-40-2.5

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, not annealed,Tol. EN EN ISO 1127, DIN EN 1027-7 TC1, grade 1.4301, 8-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, heat treated, Tol. EN EN ISO 1127, DIN EN 1027-7 TC2,TC2, grade 1.4301, 8-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, heat treated, Tol. EN EN ISO 1127, DIN EN 1027-7 TC2,TC2, grade 1.4301, 6-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, not annealed,Tol. EN EN ISO 1127, DIN EN 1027-7 TC1, grade 1.4301, 5-0.75 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, not annealed Tol. DIN EN ISO 1127, DIN EN 10217-7 TC1, grade 1.4301, 10-2 mm

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

GSW SCHWABE AG

Germany

ideally suited for large coil widths and thicknesses dual arbors for minimal deflection hydraulic wedge type expansion systems highestquality Reel Arbor with maintenancefree bearing and minimal deflection integrated hydraulically powered coil loading system for narrower coils even onesided use possible coil reels as seperate movable components proven support of large rollforming applications especially for the manufacture of welded tubes SHZR Series with variable speed drives via threephase motors and frequency inverter

Request for a quote

PEEKCHINA CO., LTD.

China

We can do secondary processing on the tubing. Tubing ends: flanging, expanding, sealing the head, welding, ect. Tubing printing: scale and ring printing. Punch holes: rould hole, elliptical hole, through hole, single side hole, square hole, shaped hole. Tubing shaping: bending, different angles and shapes forming.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The different kinds of cold drawn tubes ready on stock cover a wide range of applications: COLD DRAWN SEAMLESS AND WELDED TUBES SUITABLE FOR HONING. COLD DRAWN SEAMLESS AND WELDED TUBES INSIDE H8. COLD DRAWN SEAMLESS TUBES FOR SHAFTS. WELDED SMOOTH BORE CYLINDER TUBES INSIDE H9 OR H10. COLD DRAWN SEAMLESS TUBES FOR HYDRAULIC AND PNEUMATIC POWER SYSTEMS. Seamless and Welded Cold Drawn pipes honed or ready for honing; H8, H9 or H10. STEELGRADES AND DELIVERY CONDITIONS COLD DRAWN / HARD (+C acc. EN 10305 / BK acc. DIN 2391) No heat treatment after final cold drawing. COLD DRAWN / SOFT (+LC acc. EN 10305 / BKW acc. DIN 2391) The final heat treatment is followed by a suitable drawing pass (limited reduction of area). STRESS RELIEVED (+SR acc. EN 10305 / BK+S acc. DIN 2391) After the final cold drawing process, tubes are stress relieved in controlled atmosphere in order to reduce work hardening due to the cold forming process. ANNEALED (+A acc. EN 10305 / GBK acc. DIN 2391) After...

Request for a quoteResults for

Tubes- welded - Import exportNumber of results

114 ProductsCountries

Company type

Category

- Pipes and tubes, stainless steel (7)

- Textiles - Machines & Equipment (7)

- Pipes and tubes, steel (6)

- Welding, soldering and brazing - equipment and supplies (6)

- Pipe and tube fittings - non-ferrous metal (4)

- Pipe and tube fittings - ferrous metal (3)

- Welding, electric - equipment and supplies (3)

- Bicycle accessories (2)

- Electron beam welding - equipment (2)

- Forming - steels and metals (2)

- Heat exchangers (2)

- Hoses, pipes and tubes - plastic (2)

- Laser - cutting and welding machines (2)

- Lifts and platform elevators, car (2)

- Pipes and tubes, aluminium (2)

- SMALL METAL PARTS (2)

- Steel & Metals (2)

- Autogenous welding machines (1)

- Boilers, industrial (1)

- Burners, industrial (1)