- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tubes- seamless

Results for

Tubes- seamless - Import export

ALUMINIUMWERK UNNA AG

Germany

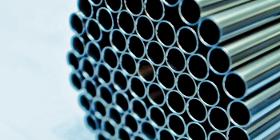

Seamless aluminium tubes can be ordered in all commercially available aluminium alloys in addition to high strength aluminium alloys which are required for more demanding applications. ALUnna has a number of extrusion presses equipped with mandrel piercing capability. This allows us to extrude a large range of extruded tubular dimensions from a number of different billet diameters. The size range for seamless extruded tubes ranges from 17 mm to 300 mm in diameter.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Durability and corrosive resistance are key criteria when it comes to precision thin wall tubing for industrial condensers. The tube mill at Superior Tube more than meets that requirement, and we supply products to a range of leading engineering companies. In the energy sector, our high quality stainless steel and nickel alloy condenser tubes are used for the cooling, heating or re-heating of fluids or gases within steam turbines that generate electricity. Condenser tubing products can be purchased from Superior Tube as seamless, welded or welded drawn tubes in a multitude of sizes ranging from 0.010” OD to 1.500” OD with wall thickness as light as .003” Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes has a long history of manufacturing high-quality tubes for nuclear fuel rods, going back to the UK’s first generation of gas cooled reactors in the 1970s. Today we support customers worldwide at the earliest stages of design engineering for new builds, plant maintenance, global life extension projects and Small Modular Reactors (SMR). Nuclear Fuel Rods and Cans Our tubes are deployed in the nuclear fuel rods and cans of advanced gas-cooled reactors. Here they endure extreme temperatures and pressures. Precision, quality, and performance are crucial. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate. The addition of copper to this grade gives it corrosion resistant properties superior to the conventional chrome nickel stainless steels, in particular to sulphuric, phosphoric and acetic acids. However, there is limited use with hydrochloric acids. It also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum. The grade is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The high precision seamless tubes manufactured at Fine Tubes begin their journey as seamless tube extrusions, in a range of different sizes. This material is reduced in size several times until it gradually reaches the exact specifications our customers require. Each time we perform a reduction process, the tube needs to be cut, cleaned and heat treated before the next one can commence. Please note that we have a minimum order value of £10,000.

Request for a quote

C+R HYDRAULICS GMBH

Germany

DIN 2391, EN 10305-1, E355+N(SR), hard chrome-plated outside 25 +/-5 µm, fit f7 Dimensional range: Outer diameter 12,0 - 140 mm

Request for a quote

EC PLAZA

South Korea

Hydrogen is an important resource that is now expanding into various fields. In particular, hydrogen vehicles require a high-pressure gas environment and have strict requirements to meet it. TRIS produces and supplies products that customers require based on the understanding of using environment. <Company Information> Tris Tube Co., Ltd is a manufacturer of precision seamless and welded tubes. The products are supplying to the various industries such as Oil&Gas, Semiconductor, Automotive, Shipbuilding, food and beverage and Gas with high pressure (Hydrogen Gas station) The products are supplied with Straight tube and Coiled tube.

Request for a quote

EC PLAZA

South Korea

Since UHP (Ultra High Purity) tubes with high corrosion resistanceas well as good internal roughness and cleanliness are needed in Semiconductor field,TRIS provides tube OD size from 1/4 inch to 2 inch for EP (Electro Polishing) process with high quality. TRIS is a supplier to Global Semiconductor manufacturers through EP companies. Since 2004, TRIS has been supplying more than 1 million meters of seamless clean BA tube every year.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

As per the norm EN 10297 specifies the technical delivery conditions for seamless round steel tubes. The tubes for mechanical applications are mainly used in those processes in which turning and CNC machines are used. The wide size range available, with OD from 21.3 to 812 mm, gives the possibility to manufacture several kinds of components for different applications: small machine parts, flanges, fittings, Archimedean screws, hydraulic cylinders for heavy machines etc.

Request for a quote

EC PLAZA

South Korea

TRIS supplies tubes of various specifications and steel grades for petrochemical plant construction. TRIS has supplied not only straight tubes but also Seamless Coiled tube with longer length. The seamless coiled tubes have many benefits with reducing welding pointsand minimized the leakage points and helping to reduce the construction period in dramatically. In 2013, TRIS developed the Seamless Coil Tube. Now, TRIS can handle various steel grades such as 904L, C-22, Incoloy825, Super Duplex etc. of Coiled Tube and Straight Tube. The longer length of Nickel alloy coiled tube is usedfor chemical injection, hydraulic control, gas detect line etc. in Oil & Gas industry. In addition to the heat exchanger tubes of TRIS of chemical plant used in severe environmentsprovide the most efficient operation conditions by stable quality control and various Ni alloys.

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

Aluminiumwerk Unna AG is specialised in the production of Aluminium tubes. The Aluminium tubes are extruded on site using two possible methods. These are either Seamless extrusion or Porthole extrusion. It is quite simple to distinguish between the two extrusion methods. In seamless extrusion, a mandrel is positioned and fixed inside the extrusion die, creating the inner contour of the tube. In porthole extrusion, the mandrel is fixed and is supported by a number of integral bridges affixed to the outer portion of the extrusion die.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Seamless tube elbows made of aluminum for welding.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

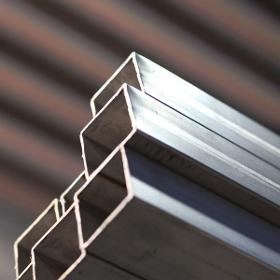

The different kinds of cold drawn tubes ready on stock cover a wide range of applications: COLD DRAWN SEAMLESS AND WELDED TUBES SUITABLE FOR HONING. COLD DRAWN SEAMLESS AND WELDED TUBES INSIDE H8. COLD DRAWN SEAMLESS TUBES FOR SHAFTS. WELDED SMOOTH BORE CYLINDER TUBES INSIDE H9 OR H10. COLD DRAWN SEAMLESS TUBES FOR HYDRAULIC AND PNEUMATIC POWER SYSTEMS. Seamless and Welded Cold Drawn pipes honed or ready for honing; H8, H9 or H10. STEELGRADES AND DELIVERY CONDITIONS COLD DRAWN / HARD (+C acc. EN 10305 / BK acc. DIN 2391) No heat treatment after final cold drawing. COLD DRAWN / SOFT (+LC acc. EN 10305 / BKW acc. DIN 2391) The final heat treatment is followed by a suitable drawing pass (limited reduction of area). STRESS RELIEVED (+SR acc. EN 10305 / BK+S acc. DIN 2391) After the final cold drawing process, tubes are stress relieved in controlled atmosphere in order to reduce work hardening due to the cold forming process. ANNEALED (+A acc. EN 10305 / GBK acc. DIN 2391) After...

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round SEAMLESS tubes are hot rolled and satisfy both the requirements of the norm EN 10210 for structural applications and EN 10297-1 for mechanical applications. These steel tubes are fully killed and are suitable for structural applications but with the possibility to reach up to 100 mm w.t., which is impossible for welded tubes. These tubes are used for the manufacture of various kinds of construction components, above all where heavy wall thickness are required. EN 10210-1/2 (structural applications) EN 10297-1 (mechanical applications)

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube bending fittings from different, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a old metal parts manufacturer from China, custom tube machined parts according to customers' design or samples. Tube machined parts means the raw material of the parts are made from tube,such as welded tube, seamless tube. The material can be carbon steel, stainless steel tube,aluminum tube, brass tube or copper tube. There are a variety of processing amplification, roughly divided into cutting, flattening, expansion, turning, milling, drilling and so on. If you have any tube machined parts need to be customized in China, welcome contact us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Pipe / tube fabricating services more than 10 years, we have produced various types of aluminum pipe bending fittings from different, include welded pipe and seamless pipe, Elliptical tube and rectangular tube. we produce Pipe / tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube frames, tube bent fittings, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloy 22, is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. The high chromium content provides good resistance to oxidizing media while the molybdenum and tungsten content give good resistance to reducing media. This nickel alloy also has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chlorine ions. Alloy 22 has resistance to oxidizing acid chlorides, wet chlorine, formic and acetic acids, ferric and cupric chlorides, sea water, brine and many mixed or contaminated chemical solutions, both organic and inorganic. This nickel alloy also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. This is beneficial in multi-purpose plants where such “upset” conditions occur frequently. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Superior Tube is committed to improving healthcare options for patients, and to helping surgeons save lives. As such, we manufacture a range of specialized welded and seamless tubing products for various areas of the medical device industry, including cardiac stents. Stents are small, expandable tubes, usually made of metal mesh, and are used to treat narrowed or weakened arteries. In patients with coronary heart disease, stents are implanted in order to open narrowed arteries during a procedure called percutaneous coronary intervention, or angioplasty. Heart stents can also help relieve chest pain and aid in the prevention of heart attacks. Ever since our tubing was used in the earliest cardiac stent implants in 1987, Superior Tube has been an industry leader in the manufacture of implant grade tubing for both coronary and peripheral stents. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloy 209 is a fully austenitic nitrogen strengthened stainless steel, having twice the yield strength and superior corrosion resistance at room temperature when compared to 316/316L or 317/317L stainless steels. This grade does not become magnetic when cooled to sub-zero temperatures or to a cold working process and has high resistance to sulphide stress corrosion cracking in both annealed and cold worked/ cold worked & aged form up to 30 HRc hardness. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloys 304 (S30400) and 304L (S30403) stainless steels are variations of the 18 percent chromium – 8 percent nickel austenitic alloy, the most familiar and most frequently used alloy in the stainless steel family. High strength, excellent corrosion resistance and minimized carbon content make Alloy 304 and 304L Stainless Steels useful for applications where welding is required. Uses include architectural mouldings and trim, welded components of chemical, textile, paper, pharmaceutical and chemical industry processing equipment. Other advantages are its resistance to oxidation, excellent formability, ease of fabrication and cleaning, excellent strength to weight ratio and good toughness at cryogenic temperatures. For severely corrosive environments,the lower content of Type 304L is preferred because of its greater immunity to intergranular corrosion. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel grades cover a wide range of compositions which result in the generation of a variety of microstructures and mechanical properties. This group of alloys is useful for the replacement of mild steel in structures and components. Stainless Steel tubes manufactured by Fine Tubes have an excellent combination of corrosion resistance, metallurgical stability and formabilityStainless steels are favoured because they are very cost effective. They also have an excellent combination of corrosion resistance, metallurgical stability, formability, and are easily welded. Their fabrication characteristics, good mechanical properties and attractive finished appearance make high quality stainless steel tubing a popular choice in a range of industries. Please note that we have a minimum order value of £10,000.

Request for a quoteResults for

Tubes- seamless - Import exportNumber of results

51 ProductsCountries

Category

- Pipes and tubes, stainless steel (14)

- Stainless steels (8)

- Pipes and tubes, steel (5)

- Pipes and tubes, aluminium (3)

- Seamless pipes and tubes - ferrous metal (3)

- Boilers, stainless steel (2)

- Forming - steels and metals (2)

- Pipe and tube fittings - ferrous metal (2)

- Pipe and tube fittings - non-ferrous metal (2)

- Casting, steel (1)

- Chains with articulated links (1)

- Clothes, women's (1)

- Drawing - steel and metals (1)

- Industrial piping (1)

- Light tubes (1)

- Mechanical transmission systems and components (1)

- Paper - Printing - Machines & Equipment (1)

- SMALL METAL PARTS (1)

- Steel & Metals (1)

- Steels, nickel (1)