- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transfer moulds

Results for

Transfer moulds - Import export

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

In the area of elastomer technology, the Zimmer Group uses the most modern production processes to manufacture sophisticated workpieces from elastomers. In addition to the transfer molding process, in which the elastomer is placed in a mold, pressed into shape with a die and vulcanized under pressure and heat, we also use the injection transfer molding process. Here, the starting materials are pressed into the mold on an injection molding machine and vulcanize out there. With these two processes, we process a wide range of elastomers such as NBR, silicone, EPDM, FPM or polyurethane. In terms of quantities as well as dimensions, the sky's the limit, because we can manufacture almost any quantity required, from special solutions in quantities of one to medium-sized small batches and large series of more than 10,000 units.

Request for a quote

HODA, UAB

Lithuania

There are a variety of methods used to process plastic. Each method has its advantages and disadvantages and are better suited for specific applications. These methods include: injection molding, blow molding, thermoforming, transfer molding, reaction injection molding, compression molding, and extrusion.

Request for a quote

SHORE AUTO RUBBER EXPORTS PVT. LTD.

India

We offer a range of moulded parts – Orings, Seals, Washers, Gaskets, Mountings, Grommets, Vibration Isolators, etc, in a range of materials including, EPDM, PVC/NBR Chloroprene, Polyacrylic, Vamac, NBR, HNBR, XNBR, Hypalon, Fluorosilicone, Silicone and FKM. Transfer, Injection and Compression Moulding Presses Available Standard Size available off the shelf with our global

Request for a quote

IMPLAST CHOCOLATE MOULDS

Turkey

Volume: 11.0 Weight: 13.0 Size: 33*33*14

Request for a quote

IMPLAST CHOCOLATE MOULDS

Turkey

Volume: 11.0 Weight: 13.0 Size: 30*30*14

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

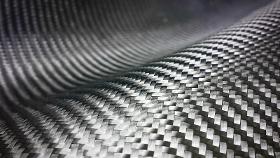

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Silicone Molding Liquid Silicone Rubber (LSR) and Silicone Transfer Molding (STM) are widely used in the medical device industry for the production of various medical device components such as catheters, tubing, connectors and handles or grips. The process of LSR molding involves injecting liquid silicone rubber into a mold cavity, often over electrical connections or a circuit board. It is then allowed to cure or solidify into the desired shape.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Silicone transfer molding is another manufacturing process used in the medical device industry. It is similar to LSR molding but focuses on more delicate electrical connections or instruments. It is a 2-step process that involves the manual molding of components into shape.

Request for a quote

DLR ELASTOMER ENGINEERING

United Kingdom

As a rubber moulding company, engineered bespoke rubber mouldings are developed on-site in collaboration with mould designers. The range of injection, compression, and transfer moulding presses on-site enables us to provide clients with various solutions. Rubber, alongside woven fabrics and custom made inserts, are regularly used in mouldings.

Request for a quote

ELEMY LTD

United Kingdom

GRP FRP Flanges form a rim that protrudes from the end of a pipe. They have several holes that allow two pipe flanges to be bolted together, with a connection formed between the two pipes. A gasket may be fitted between two flanges to improve the seal. Flanges available: DN 25 – DN 2500 in GRV and GRE Cylindrical or Conical Inner configuration Pressure ratings 3, 6, 10, 16, 20, 25 and 32 bar Stub Flanges by Resin Transfer Moulding offer an excellent competitive solution with very high and constant quality. The dimensions comply with the specified standards for each particular diameter and pressure class. Various internal diameters are available to match all types of pipe. Diameters are available from DN 25 mm to DN 2500 mm. Pressure ratings from 3 up to 40 bar. SMC Stub Flanges Standard resin is Vinylester Derakane 411 or equivalent. RTM Stub Flanges Epoxy resin, Derakane 470 or other resin on request.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Introducing Caldor's Nozzle Band Heaters, the ultimate solution for precise and efficient heat transfer in injection molding and extrusion processes. Our robust heaters are engineered to deliver outstanding performance in various industrial applications, ensuring optimal material processing and end-product quality. These heaters are constructed with high-quality materials, providing a compact design and excellent heat distribution. The use of advanced ceramic insulation minimizes heat loss and enhances energy efficiency, while the built-in thermocouple ensures precise temperature control. Key Features: Customizable dimensions to fit various nozzle sizes Temperature range: up to 450°C Wattage: up to 100 watts per square inch Uniform heat distribution for consistent results Durable construction for long service life Easy installation and maintenance

Request for a quote

J-FLEX RUBBER PRODUCTS

United Kingdom

Whatever your requirements, J-Flex can help with a vast array of bespoke rubber mouldings, large or small and in a wide range of polymers. We guarantee you top quality mouldings every time using our ISO9001 batch traceability procedures. We sample new moulds to your complete satisfaction and approval before we commence bulk supply. Our polymer range is vast – we can offer: Natural, Neoprene, Nitrile, EPDM (including EPDM conforming to EN45545:2013 + A1:2015), Butyl, Hypalon®, HNBR, CXNBR, Silicone, Fluorosilicone, Viton™, Fluoroelastomers, Aflas® and Perfluoroelastomer. We mould by compression, transfer and injection moulding techniques. Bellows Discs Covers Gaiters Boots Vibration Mounts Grommets Diaphragms Sheets Rubber / Metal Bondings Cups Suckers Balls Gaskets ‘O’-Rings Rubber Seals J-Flex – for rubber mouldings, including Silicone, FKM, EPDM and much more.

Request for a quote

DP SEALS LTD

United Kingdom

DP Seals manufacture precision custom rubber mouldings designed and manufactured to the highest possible tolerances. This includes simple products right up to hugely complex dual material, conductive and semi-conductive rubber components. We specialise in transfer and compression moulding and also have expertise in rubber to metal bonded seals and mouldings.

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Coatings made of PFA and PVDF fluorine-based thermoplastics provide safe protection against corrosion even on exposure to aggressive media. Because its molecular structure resembles that of PTFE, PFA is almost universally resistant to chemicals. Other special features of PFA linings are their wide range of operating temperatures and easy cleaning due to the material’s non-adhesive nature. In many applications, this makes it possible to replace stainless steel with a raw material which is not only much more economical but also easier to process. Because coatings are applied in a thermoplastic transfer-moulding process, it is necessary to account for certain design aspects which our team will gladly discuss with you in advance.

Request for a quoteResults for

Transfer moulds - Import exportNumber of results

15 ProductsCountries

Category

- Chemical industry - machinery and equipment (1)

- Flanges (1)

- Heating, industrial - installations and equipment (1)

- Import-export - medical and surgical equipment (1)

- Joints, pneumatic (1)

- Medical Equipment (1)

- Metal industrial presses (1)

- Rubber - technical items for industry (1)

- Rubber products (1)

- Rubber seals (1)