- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- trailing leads

Results for

Trailing leads - Import export

GSW SCHWABE AG

Germany

Our sequence-controlled system includes a precision welding head and precise cutting and positioning devices. The two integrated Hydraulic Shears and the strip clamps can be moved so that the leading and trailing strip ends can be fitted precisely. For those who like it less automated but more cost-effective, we have developed a simpler technology – using just one Hydraulic Shear and fixed clamps. The strip ends are positioned manually here – this is supported by an easily accessible hand lever to individually activate the pneumatic clamps. A double edge guide with vertical rollers centers the new strip and can be adjusted also decentral for alignment. The actual welding process is taken over by the operator himself.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The containers are picked up by the in feed star wheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells. The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point. Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. The label with the glue strip on its leading edge is transferred to the container. This glue strip ensures an exact label positioning and a positive bond. As the container is rotated during label transfer, labels are applied tightly. Gluing of the trailing edge ensures proper bonding. Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish

Request for a quote

SIA ATTA-1

Latvia

Very small installation depth: < 20 mm Without claws. With rotary control, two-way switch and soft-catch. 2-wire connection (neutral conductor not required) Optimised for dimming of retrofit LED lamps (LEDi). For dimmable Retrofit-LEDs (LEDi). For dimmable Retrofit-LEDs (LEDi) with conventional or electronic transformers. For incandescent lamps, 230 V tungsten halogen lamps, low-voltage halogen lamps with conventional or electronic transformers and dimmable energy-saving halogen lamps. Mix operaton of LEDi with conventional loads possible. With manually adjustable operating mode: trailing / leading edge control. With adjustable minimum/maximum brightness. Low-noise level by MOSFET transistors. With electronic short-circuit protection. With electronic overload protection. Without cover plate. Rated voltage: 230 V~, + 10% / - 10% Rated frequency: 50 Hz/60 Hz Nominal power: 2 - 100 W/VA (leading edge control) Nominal power: 2 - 400 W/VA (trailing edge control)

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

In addition to the strip speed, VRecoS also records up to three further tracks, such as the rolling force or the strip thickness at the ingoing and outgoing ends of the mill. The measurement protocols can be stored, printed out and distributed by e-mail. The measured values are recorded as a function of length. The recording frequency can be set with a scanning rate of 2 ms. Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed, even subsequently. The signals are recorded using a data collector belonging to the scope of supply. Its electronics with input and output modules is designed for installation in switch cabinets or desks in interference-proof 24 Volt top-hat (DIN) rail technology. It transmits the data via a network cable to the Windows recording computer which can be supplied by Vollmer or by the customer.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

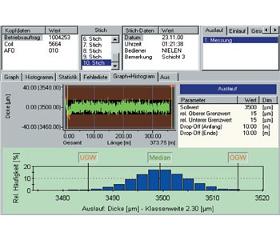

VGraph is the software package for the recording and visualisation of data with extensive statistical data evaluation options. It synchronously records up to 16 measurement values – for example thickness, width and speed of the strip, rolling force or strip tension – on a production line, stores them and evaluates them statistically. With statistical functions such as histograms, Cp and CpK values and error lists, VGraph provides valuable decision aids for the evaluation and further use of the coil produced. The diagnostic instruments allow optimisation of the rolling process and the line engineering. The optional FFT analysis detects periodic fluctuations in the strip thickness. VGraph meets the needs of day-to-day strip production. One example: Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed – even subsequently – in the statistical evaluations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Trailing leads - Import exportNumber of results

5 ProductsCountries