- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- torque testing

Results for

Torque testing - Import export

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

Torque Converter & Welding Testing Machine

Request for a quote

AAAGILER GMBH

Germany

Rent professional measuring equipment: Find our range of powerful measuring equipment for hire here, such as sound level meters, torque testing equipment, spring testing systems or precision balances.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Simple assembly line/workshop torque tester for torque wrenches. The Wrenchmate is a robust, simple, user-friendly unit for checking and setting torque Wrenches. It is strong and robust and designed especially for a workshop environment. The Wrenchmate can be fitted to a wall, steel structure or at the end of a bench or workstation. The Wrenchmate has a large, easy-to-read screen with clear LED digits and a clever dual-colour torque display that is visible in all light conditions. The torque tester can also be switched between Nm and lb.ft measurement units. Three versions are available for testing tool torque up to 1100 Nm, all of which are supplied with a 12V PSU power supply and a traceable calibration certificate. Key Features Aluminium alloy housing with powder coated finish Accuracy ±1% reading (±1 digit) over the operating range Alternate measurement units from Nm to lb.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Dial Indicating Torque Screwdriver with mNm scale Tohnichi's MTD series torque screwdriver is suitable for inspection and tightening of very small screws, e.g. small torque motor shafts or the like. Torsion bar mechanism makes accurate measurement possible. With bi-directional scale plate, it can be used for both retightening and loosening torque testing methods. Memory pointer captures peak torque. Applicable for international use including the EU region. Compliant with calibration procedures of ISO 6789 Type I Class D. Key Features: - Bi-directional scale - Peak torque indication via Memory Pointer - Accuracy and calibration compliant to ISO 6789 type I class D - Bit insert #2 Tohnichi Shipping List: - Screwdriver MTD - Calibration Certificate (ISO/JIS) - Operating Manual - Special Bits Cross #0, Slotted 0.15x1, 0.2x1.5, 0.3x2 Options: - Alternatively with english units (ozf·in) available. Metric scale (gf·cm) on request.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Tohnichi's FTD-S series torque screwdriver is ideal for inspecting tightened screws. With bi-directional scale plate, it can be used for both retightening and loosening torque testing methods. Memory pointer captures peak torque. Model FTD8N-S and FTD16N-S comes with auxiliary tightening tool ("T-Grip") as standard accessory. Applicable for international use including the EU region. Compliant with calibration procedures of ISO 6789 Type I Class D. Key Features: - Bi-directional scale - Peak Torque indication via Memory Pointer - Coloured dial plate - Accuracy and calibration compliant to ISO 6789 type I class D - Tool insert 1/4 inch Shipping List: - Screwdriver FTD-S - Traceable Calibration Certificate (ISO/JIS) - Operating Manual Options: - Models with metric scale (gf·m, kgf·m) on request. Related Products Insert Bits with 1/4“ hex drive acc. DIN 3126 E6.3

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Essential for direct reading and high-capacity torque wrench calibration! Mechanical loaders increase the accuracy ot torque test results while simultaneously reducing technician fatigue from pulling or pushing on torque wrenches during testing. A mechanical loader is the perfect accessory to increase the repeatability and productivity of the System 5 Digital Torque Tester. The drive system for each loader assures true 90-degree force application to eliminate force angle error in testing. In addition, the loaders mechanical advantage reduces technician effort and fatigue, particularly in high-capacity tool testing. SR Mechanical Loaders use the highest quality ball screws to assure smooth operation and extended service life. Welded steel frames and rigid transducer mounting plates assure torque load is properly resisted. Optimized gearing selection reduces physical effort to operate, enhancing productivity and ergonomic safety.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Accurate torque wrench testing at a very affordable price! Sturtevant Richmont's VeriTorq is an excellent tester for intermediate checks (simple checks between calibrations) of all types of tools and for calibration of clicker-type torque wrenches and clutch-type torque screwdrivers. VeriTorq brings accurate torque wrench testing to the “That can save me money!” level – for companies large and small. If you have 10 or more torque wrenches that you send out for calibration – whether to the manufacturer or an independent laboratory – you can now bring those calibrations in-house and turn expense to profit. VeriTorq is so simple to use and so affordable that it can even be put at the assembly line for use at the start of each shift. How simple? Perhaps 15 minutes to install. Maybe another 15 minutes to learn to use accurately and efficiently. Four buttons operate everything simple. You could have your first two torque wrenches calibrated within an hour of opening the box.

Request for a quote

DIETZ GMBH

Germany

Customised production to your specifications: We work very closely with you when it comes to producing torsion springs. Torsion springs are produced in accordance with your specifications based on drawings, prototypes or sketches. We manage the development process of the spring until it is ready for serial production. We produce torsion springs with wire diameters of 0.20 to 4.00 mm, with or without torque testing. Wire coatings: Galvanised, ZnAl-plated, Red-coated, Nickel-plated, Polished nickel, Phosphated, Brass-plated,Silver-plated.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Digital torque meter with data processing function. Tohnichi's TME3 is suitable for checking torque on bottle caps, starting torque test, strength test, and twisting test, etc. Designed to measure rotating torque of precision parts. Ideal for cap testing. Intuitive icons indicate modes: Run, Peak, 1st 2nd Double Peak, Data/Parameter Setting. The 1st and 2nd peaks holding function, especially for bottle cap measurement. Can detect primary peak opening torque (when cap begins turning) and secondary peak (when bridges break). The drop width required for peak detection can be set to prevent mistaken detection of the unstable region. Easy to read LC display gives reliable visibility. Special teardrop shaped poles allows chucking from a minimum diameter of 7 mm to maximum 190 mm. Pole anchors use a corotation prevention mechanism to grasp your work firmly. With the optionally available calibration equipment, the tester can be calibrated by the operator himself if required.

Request for a quote

MOOG GAT GMBH

Germany

GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio. GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently. The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

DPFR-004 Customized Solution for friction measurement of transmission A hand-held enclosure with integrated torque transducer, start buttons and 1 display for torque andf speed. Is used to the friction torque of tapered roller bearing set or monitor. portable Safety circuit by two-hand operation Constant load independent test speed

Request for a quote

ETH MESSTECHNIK GMBH

Germany

The specimen is cyclically loaded in a cold-heat oven to freely programmed load follow with torque. Rotation angle and temperature are documented with. Applicationfield Automotive industry; Optimization of the granular mixture of rubber elements of a window motor.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Spring brake - Seat adjustment slip clutch Left and right torque control Test samples on mounting carriage compact, slim design Constant load independent test speed selectable rotation direction and speed additional storage for the elimination of lateral forces quick change by magnetic holder

Request for a quote

ETH MESSTECHNIK GMBH

Germany

The transducer is suited for the most varied measurement duties on threaded fasteners, to check and adjust assembly tools, like screwdrivers and spanners, and to sense loosening torques, etc. It can also be deployed in blocked mode to test torque wrenches. The device is powered wirelessly and the electrical output is wireless, as well. Hence, there is practically no wear on the device. This sensor is suited for cyclical as well as continuous testing of tools. As the sensor is designed to be torsionally rigid any errors due to it are minimized. No service needed because of contactless data aquisition High interference immunity due to amplified active signal High accuracy due to frequency modulation and strain gage technology Power supply Optional angle detection torque ranges from 1 Nm up to 10.000 Nm torque with square drive with or without angle (w) function Variant bracket for quick assembly

Request for a quote

ETH MESSTECHNIK GMBH

Germany

3 measurement range from ± 0 - 0,5 Nm to± 0 - 50 Nm DRDML | DRDMS | DRDMN for mechanical connection to Maxon gearboxes with contactless data acquisition as a complete drive and torque measuring unit Test bench construction Screwing technology

Request for a quote

MAGTROL

Switzerland

Magtrol’s Cogging Test System is a stand-alone test system designed to control and measure Detent Torque, Cogging Torque and Friction Torque. The test System includes a precision geared motor, a TS Series Torque Sensor integrating a 5 000 pulses encoder. CTS 100 to CTS 102 have a built-in security clutches to avoid system overload by mishandling when not in use. The geared motor drives the MUT (Motor Under Test) at a low speed from 1 to 10 rpm (respectively 8 rpm for CTS 103 and CTS 104), while acquiring its cogging torque related to angle position. The torque measurement covers a range up to 1 N∙m (depending on the selected torque sensor) with an accuracy of ± 0.1 mN∙m (for TS 100 – 50 mN∙m and TS 101 – 100 mN∙m). The executable software controls the system and displays acquired data. It provides accurate peak-to-peak measurement of cogging torque and displays X-Y or polar graphs as well as FFT analysis. ... more information www.magtrol.com

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TEST GMBH

Germany

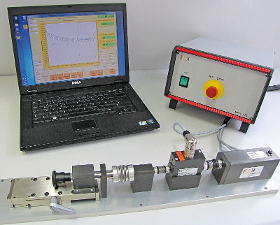

Torsion testing machines by TesT are executed as horizontal machines with torsionally rigid machine bed. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

The testing machines of model series 215 were developed and built for applications with extremely small measuring ranges, below 0.1 Ncm, and highest precision. They are for example used in watch idustry or medical technology. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

For measuring ranges up to 600 Nm Torsion testing machines by TesT are also available as vertical machines, equipped with T-slot table and height-adjustable drive. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

TesT electrical torque transducers are available as static reaction sensors and with rotary axle for dynamic applications. The requirements of our customers to precise, durable devices for industrial applications are fulfilled. They are easy to handle, from high quality and long life span. Other dimensions, measuring ranges and executions are available on request. TesT delivers all electric force and torque transducers with TEDS chips (TEDS = Transducer Electronic Data Sheet nach IEEE 1451.4). The electronic units of the model 813 and the TesTController 850-USB may recognize sensors equipped with TEDS chips, read their properties and calibration data, and automatically calibrate them. Thus, these electronic units operate with dozens of different sensors, so that a complex recalibration is not required.

Request for a quote

TEST GMBH

Germany

The mobile evaluation electronics TesT 813 meet all demands that precise measurement processes require. They have been designed for use with TesT force and torque transducers, but they are also suitable for other resistance-based transducers. The devices consist of a process-controlled electronic unit with advanced software under Windows CE. Various functions are adapted to the daily requirements of quality assurance. An integrated data logger allows f.e., saving peak values and/or curves in xls files. Basic settings, that had been stored once, even remain when the device has been switched off. Because of the high measurement frequency of up to 2 kHz the model can be used for static and dynamic measurements. Sensors that are equipped with TEDS (Transducer Electronic Data Sheet according to IEEE 1451.4) chips can be recognized and automatically calibrate. Thus, the units may operate with different sensors, so that a complex recalibration is not required.

Request for a quote

ASG, DIVISION OF JERGENS, INC.

Italy

ASG DTT Series Digital Torque Testers are used for setting, verifying, and measuring torque. The ASG DTT Series are equipped with many advanced features including data collection. Portable and easy to use, these torque testers can test screwdrivers and manual tools, however, they are not for use with impact tools. Perform on-the-spot calibration with torque accuracy of +/- 0.5% full scale.

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The latest technology Datum Electronics Series non-contact rotary Torque Sensors have been designed to fit with most applications where the measurement of accurate rotary torque and power measurements are required. The M425 Rotary Torque Sensor fits in line with the drive train or test bed, using standard key-way shafts. The Datum M425 Rotary Torque Transducer represents a quantum leap forward for anyone looking to measure torque and power with high accuracy and repeatability using up to 24 bit resolution. The M425 torque sensors give the customer control over their tests with torque sample rates selectable at any time from 1sps up to 4000sps as standard. With rpm measurement based on up to 30 pulses per revolution, the M425 is now the complete torque transducer for measuring torque and power on any rotating shaft. When paired with the Datum Universal Interface (DUI), the M425 Torque Sensor gives customers a ... ** Click for more **

Request for a quoteResults for

Torque testing - Import exportNumber of results

25 ProductsCompany type

Category

- Measurement and control instruments (5)

- Testing equipment (4)

- Measurement - Equipment & Instruments (3)

- Sensors (2)

- Tightening wrenches (2)

- Calibration equipment (1)

- Helical springs (1)

- High-pressure cleaning machines (1)

- Mechanical transmission systems and components (1)

- Medical and surgical instruments (1)

- Precision measuring instruments (1)