- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools for watchmakers and the watchmaking industry

Results for

Tools for watchmakers and the watchmaking industry - Import export

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

APEX TOOL GROUP GMBH

Germany

Cleco's Right Angle Grinders meet the challenging requirements of many industries. They feature a high-performance 1,25 kW motor, to maximize material removal rates for the most demanding applications. The Right Angle Grinders’ internal components are built to last long, and are protected by a dual-layer, high-impact housing providing extreme durability. The most important informations: -Available in 100, 115 and 125 mm disc sizes -Versatile 270° adjustable guard -Intelligent Spindle lock for quick and easy abrasive changes -Quieter operation with rear exhaust overhose standard -Ergonomic, anti-vibration handle for increased comfort and less operator fatigue -Designed to fit all Type 27, Type 27 threaded hub and Type 1 abrasive discs

Request for a quote

APEX TOOL GROUP GMBH

Germany

Manage up to 16 tools with only one controller. The new LiveWire™ generation combines the freedom and flexibility of cordless tools with real-time wireless transmission and up to 1700 rundowns per battery charge, meeting highest security standards. Designed to maximize efficiency and productivity, the LiveWire system has the ability to use up to 16 tools with a single controller, allowing each tool to communicate directly with the plant network.

Request for a quote

APEX TOOL GROUP GMBH

Germany

Compact, light, tough Cleco® updates the product range of pneumatic impact wrenches with a new mini compact model with 1/2" drive. The CV series is a universal impact wrench, designed for industrial production, repair and maintenance. Lightweight, balanced and with a comfortable design, the CV series provides fastening performance at an unbeatable value. All impact wrenches of the CV series are equipped with a powerful twin hammer mechanism. Also available in the common drive sizes 3⁄8-, ¾- and 1 inch. All advantages of the new Cleco® CV-375R-4 at a glance: - High-efficiency air motor - Twin hammer impact mechanism - Variable speed trigger - With ring anvil - No-charge modular muffler system - Max Applied Torque – 560 Nm - Max Breakaway Torque – 690 Nm - Free Speed – 8000 RPM - Lenght 157 mm - Weight 1,3 kg - Impacting Sound Level* 87 dB(A)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

APEX TOOL GROUP GMBH

Germany

• 3” x 8” (70mm x 198mm) pad size • Standard with a vinyl face pad for PSA mounted abrasives • 1/8” orbit pattern for fine finishing • Hook & Loop pad available as option

Request for a quote

APEX TOOL GROUP GMBH

Germany

The Apex µ-Guard line of Covered Drive Tools is the tool of choice for enhancing operator safety in almost all leading assembly plants. Apex® µ-Guard ™ free-spinning covered drive tools increase operator safety by significantly reducing or eliminating pinch points when operators are wearing gloves. Apex µ-Guard provides a protective barrier between genuine Apex fastener tools and your finely finished workpiece, thereby delivering the proven Apex performance plus the best protection available against in-system damage. The free-spinning design provides maximum protection for polished and highly sensitive surfaces. Apex has solutions for all aspects of safety on an assembly line when it comes to fastener drive tools. In addition to our line of Covered Bits, Bit Holders, Sockets, Extensions, and Universal Swivel Wrenches, as well as µ-Guard Gap Covers to eliminate the gap between a socket and an extension or between the right-angle power tool and a socket / extension.

Request for a quote

KRAMSKI GMBH

Germany

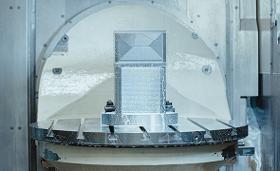

In stamping technology, many very different technologies can be integrated into the stamping process, such as assembling two or more parts, contact riveting, resistance and laser welding, laser marking of parts, or thread forming. Our high-precision tools, thereby, create a basis for production that is, over its lifetime, very high quality and economical. The stamping process is accompanied by a 100 % quality control of the functional design dimensions.

Request for a quoteResults for

Tools for watchmakers and the watchmaking industry - Import exportNumber of results

9 ProductsCountries

Company type