- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools factory

Results for

Tools factory - Import export

ACKOR MOULD LIMITED

China

We are factory for injection tools and molding in automotive, electronics and medical industries.

Request for a quote

MECANIC SYSTEMS SA

Belgium

Mecanic Systems was one of the first in Belgium to put their faith in this revolutionary "LASER" blanking technology. A LASER transforms electrical energy into a laser beam oriented by mirrors that can be focused on a surface diameter of less than 0.2mm. As a factory tool, the laser is rapid, free from wear and tear and other constraints and of high precision. . This technology has the advantage of having no limit in terms of the geometry of the item, presents no deformation or relief in terms of cutting, and is accurate to +/- 0.1mm. Mecanic Systems, in a permanent state of evolution, regular invests in machines that are increasingly efficient, reliable, rapid and productive thanks to their automatic loading and unloading systems.

Request for a quote

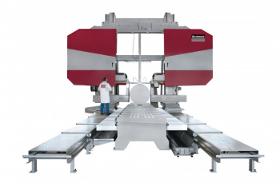

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

MRT MANUAL RETURN BOLT TENSIONER Our economy range of bolt tensioners offer low-cost tensioning solutions. Incorporating our unique quick-release bridge adaptation, a range of adapter kits provide maximum flexibility. Piston stroke limit indication Piston/cylinder misalignment compensation Bolt coverage from 1" to 3-1/2" with just 6 tools Designed to fit BS1560/ANSI B16.5/API flanges Unique quick-release bridge adaptation Application specific tooling available. Contact factory for details. Piston stroke: 15mm (excluding MRT1 - 10mm) Max tool pressure: 21,750 psi (1,500 bar) Bolt protrusion above nut: 1 x bolt diameter ‘D’ includes an allowance for tool removal after bolt tightening with 15mm tool stroke Weight excludes puller sleeve To make a complete MRT Tensioner, choose an Adapter Kit and a Load Cell. Semi-compatible with SRT tensioners. Only compatible with SRT Bridges; NOT puller sleeves. SRT Puller Sleeves cannot be used with MRT Load Cell.

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

SRT SPRING RETURN BOLT TENSIONER The Spring Return design dramatically increases productivity and safety on the job site when compared to older technology manual return tensioners. Piston overstroke prevention Piston stroke indication Compatible with MRT Tensioner range Unique quick release bridge adaptation Piston/cylinder misalignment compensation Bolt coverage from 3/4" to 4" (20 - 115 mm) with just 8 tools Designed to fit BS1560/ANSI B16.5/API flanges Fully enclosed load cell design eliminates entry of debris into piston retraction mechanism Piston over-stroke eliminator to prevent over stroking and blowing a seal Twin hydraulic couplings for multiple tool connections Requires stud to protrude above nut by 1 x bolt diameter Application specific tooling available. Contact factory for details. 10 mm piston stroke Max tool pressure: 21,750 psi (1,500 bar) Bolt protrusion above nut: 1 x bolt diameter (minimum)

Request for a quote

INFICON AG

Liechtenstein, Principality of

INTEGRATED MANAGEMENT OF TOOL RECIPES Increasing complexity of manufacturing and requirements for better process control requires better integration and management. Seamless integration of FDC and Factory Automation and Equipment Control is critical for providing accurate excursion prevention and tight control over the operation of factory equipment. FabGuard™ Recipe Management System helps Semiconductor, Display and Solar manufacturers meet these challenges by providing central archival and management of process equipment recipes. As an add-on to the FabGuard Fault Detection and Classification System, FabGuard FG-RMS expands existing FabGuard systems to include the capabilities required to manage tool process recipes across the factory. CENTRAL MANAGEMENT INCREASES PRODUCTIVITY FabGuard provides central management of tool process recipes using the familiar and robust FabGuard infrastructure. Engineers can view, edit, deploy and manage process recipes from their desktop or...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tools factory - Import exportNumber of results

6 ProductsCompany type