- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool turret

Results for

Tool turret - Import export

EWS WEIGELE GMBH & CO. KG

Germany

Emulsion can do more than just cool... At least when using EWS Spinjet, the coolant is used to drive a turbine which allows the tool to rotate to up to 50,000 rpm, depending on the type. The turret's tool drive stops moving during this process! See the attached flyer for the technical requirements and details. Download Manual: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Mori seiki Model SL 154 SY Year 2004 Condition Used Control Unit MSX 805 MAPPS Turning length 519 mm Turning diameter 430 mm X-Axis travel 230 mm Z-Axis travel 520 mm Spindle bore 56 mm Tools on turret 12 Rotating tools 12 Spindle speed 6000 rpm

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer INDEX Model ABC 65 Year 2002 Condition Used Made in Germany Control unit SIEMENS Sinumerik X-Axis travel 90 mm Y-Axis travel +/- 50 mm Z-Axis travel 280 mm Number of axis 4 (with C-Axis) Spindle speed 5000 rpm Max. Swing 65 mm Working length 280 mm Motor power 35 kW Number of Turrets 2 Turret 1 7 driven tool stations Turret 2 System with 6 dovetail slide ways Bar feeder L 5140 x W 850 x H 1300 mm

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: FANUC 31i Number of axes: 7 Stroke Y axis: -/+ 40 mm Stroke Z1 axis: 340 mm Stroke X1 axis: 180 mm Stroke Z2 axis: 440 mm Stroke X2 axis: 195 mm Rapid traverse rate X axis: 30000 mm/min Rapid traverse rate Z axis: 30000 mm/min Rapid traverse rate Y axis: 10000 mm/min Spindle nose: DIN 55026 A size 4 Spindle through bore: 42 mm Max. spindle speed: 8000 rpm Spindle power: 7 kW Counter spindle nose: DIN 55026 A size 4 Counter spindle through bore: 26 mm Max. counter spindle speed: 8000 rpm Counter spindle power: 3.8 kW Type of tool holders: VDI 25 Turret indexing time: 0.4 s/pos Turret 1: SAUTER Number of tool stations - Turret 1: 12 Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 6000 rpm Turret 2: SAUTER Number of tool stations - Turret 2: 12 Number of tool stations driven - Turret 2 12 Max. speed driven tools - Turret 2: 6000 rpm + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: Fanuc 0i-TB Number of axes: 7 Max. cutting diameter: 42 mm Max. turning length: 100 mm Stroke Z1 axis: 246 mm Stroke X1 axis: 165 mm Stroke Y1 axis: +/- 40 mm Stroke Z2 axis: 525 mm Stroke X2 axis: 70 mm Rapid traverse rate X axis: 18000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Spindle through bore: 43 mm Min. spindle speed: 60 rpm Max. spindle speed: 6000 rpm Increment C-axis: 0.02 ° Spindle power: 11 kW Counter spindle through bore: 36 mm Min. counter spindle spindle speed: 67 rpm Max. counter spindle speed: 7000 rpm Counter spindle increment C-axis: 0.02 ° Counter spindle power: 5.5 kW Max. tool holder cross-section: 20 mm Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 4000 rpm Indexing time - Turret 1: 0.25 s/post Number of tool stations - Turret 2: 6 Indexing time - Turret: 0.20 s/post Live tools power: 2.5 kW + EQUIPMENT INCLUDED Machine visible under power

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2003 CNC control : MITSUBISHI Meldas 635LCC Stroke X1 axis : 170 [mm] Stroke Z1 axis : 200 [mm] Stroke X2 axis : 110 [mm] Stroke Z2 axis : 395 [mm] Stroke X3 axis : 110 [mm] Stroke Z3 axis : 170 [mm] Type of tool holders : VDI 20 Spindle for collets : Taille 48 DIN 6343 Spindle throughbore : 42 [mm] Min. spindle speed : 80 [rpm] Max. spindle speed : 8000 [rpm] Increment C-axis : 0.001 [°] Spindle power : 7.5 [kW] Counter spindle throughbore : 42 [mm] Min. counter spindle spindle speed : 60 [rpm] Max. counter spindle speed : 6000 [rpm] Counter spindle increment C-axis : 0.001 [°] Counter spindle power : 2.2 [kW] Max. turning diameter : 140 [mm] Number of tool stations - Upper turret : 12 Number of tool stations driven - Upper turret : 12 Max. speed driven tools - Upper turret : 4500 [rpm] Number of tool stations - Lower turret : 12 Number of tool stations driven - Lower turret : 12 Max.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

The tools HGx-1, -2, -4, -11 machine bores, complex inner contours and fillets. Depending on the pressure supply, tools types HGx-5, -7 (integrated) and HGx-9, -10, -19 (external) machine rotationally symmetrical contours. HGx-20 and -29 are intended for narrow cylinders and thin-walled components. As accessories, ECOROLL offers hydraulic units, rotary units for the connection of turret machines. Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

CNC turning and autolathe part Xu Feng capable to make the diameter can range from1mm to 300mm and tolerance can reach 0.02mm,part material can be Steel ,Aluminum,copper ,brass ,brozen and plastic etc,we has CNC turning machine & automatic lathe 20 sets to meet client's big demand for short leadtime and fast delivery Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production. CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret, with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result.

Request for a quote

YILMAZ MACHINE

Turkey

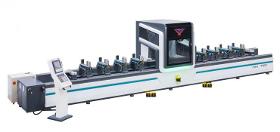

AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the six sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time. An additional magazine for the saw blade with 350 mm dia. ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the 5 sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time.An additional magazine for the saw blade with Ø350 mm ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

M SERVICES SRL

Italy

The CNC machine, mod. TB412Y is designed for reduced tooling and programming time. Is a double spindle machine and it has got an upload station on self-positioning rollers, able to receive bars from diameter of 12 mm up to 110 mm, variable from a length of 150 mm up to 3000 mm. Ground pliers and micro filtered refrigeration allows machining of shafts without damages of the chrome surface. The 12 positions, motorized tool turret, on which you can install up to 24 tools, has got an Y axis for milling and holes machining , also off-axis. The unload of the workpiece from the sub -spindle is totally automatic. The simplicity of the use, the high versatility and precision in machining, make model TB412Y an extremely competitive machine, making it possible whoever to realize quickly any kind of chromed bar. The software, made by us, is integrated with CNC SIEMENS 840 Di, and it is customizable.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holders for machines: Multiplex 610 (12 tool mounts turret), 615, 620, 6200 (12 tool mounts turret), 6200 Y, Multiplex3 8200 Y, 610 (16 tool mounts turret), 6100, 6100 Y, 6200 (16 tool mounts turret), 630, 6300, Super Quick Turn 10 (16 tool mounts turret) Quick Turn Nexus 200 M / MS / MSY (12 tool mounts turret), 250 M / MS / MSY (12 tool mounts turret) Super Quick Turn 15 M, 18 M, 200 M (12 tool mounts turret), 250 MY (12 tool mounts turret) Quick Turn Nexus 100 M/MS/MSY Quick Turn Nexus 200 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 250 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 300 / M / MY, 350 / M / MY, 400, 400 / M Super Quick Turn 28, 30, 300 M / MY, 350 M, 10 M/MS, 100 M, 10 M/MS, 100 M, 200 M (16 tool mounts turret), 250 M (16 tool mounts turret) Available in the following versions: Square locking drive radial Turning Tool holder axial Boring bar holder with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Live Tools for machines: Multiplex 610 (12 tool mounts turret), 615, 620, 6200 (12 tool mounts turret), 6200 Y, Multiplex3 8200 Y, 610 (16 tool mounts turret), 6100, 6100 Y, 6200 (16 tool mounts turret), 630, 6300, Super Quick Turn 10 (16 tool mounts turret) Quick Turn Nexus 200 M / MS / MSY (12 tool mounts turret), 250 M / MS / MSY (12 tool mounts turret) Super Quick Turn 15 M, 18 M, 200 M (12 tool mounts turret), 250 MY (12 tool mounts turret) Quick Turn Nexus 100 M/MS/MSY Quick Turn Nexus 200 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 250 M/MS/MSY (16 tool mounts turret) Quick Turn Nexus 300 / M / MY, 350 / M / MY, 400, 400 / M Super Quick Turn 28, 30, 300 M / MY, 350 M, 10 M/MS, 100 M, 10 M/MS, 100 M, 200 M (16 tool mounts turret), 250 M (16 tool mounts turret) Available in the following versions: BENZ Solidfix® axial BENZ Solidfix® radial BENZ Solidfix® offset Collet Chuck axial Collet Chuck radial Collet Chuck radial offset Collet Chuck swiveling

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Live Tools for machines: Biglia B42 Biglia B111 Daewoo PUMA 200 Duplomatic VDI 30 Hyundai Kia SKT 100 Weiler DZ 42 (12-fach Revolver \ 12 tool mounts turret) Weiler DZ 65 YCM GT 200 MA Biglia B56 Biglia B200 Hyundai Hit 250 M Hyundai Hit 250 S Topper TB 25 YMBL Available in the following versions: BENZ Solidfix® axial BENZ Solidfix® radial BENZ Solidfix® offset Collet Chuck axial Collet Chuck radial Collet Chuck offset Collet Chuck swiveling

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Static tool holder for machines: Biglia B42 Biglia B111 Daewoo PUMA 200 Duplomatic VDI 30 Hyundai Kia SKT 100 Weiler DZ 42 (12-fach Revolver \ 12 tool mounts turret) Weiler DZ 65 YCM GT 200 MA Biglia B56 Biglia B200 Hyundai Hit 250 M Hyundai Hit 250 S Topper TB 25 YMBL Available in the following versions: Square locking drive radial right Square locking drive radial left Turning Tool holder axial right Turning Tool holder axial left Boring bar holder

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VACUUM EL SYSTEM LTD.

Bulgaria

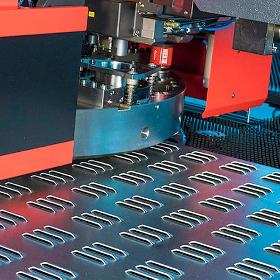

Vacuum El System provides CNC punching, forming and tapping of parts with a variety of standard as well as custom tools. We operate an Amada punching centre with a capability of 1800hpm, which allows for a very high throughput, while still maintaining high quality. Maximum sheet size without repositioning is 3000mm x 1500mm and 5000mm x 1500mm with single repositioning. Benefits: Multi-purpose turret for efficient tool selection Scratch-free processing with floating brush table Dedicated CAM and Nesting software for optimal material utilization

Request for a quoteResults for

Tool turret - Import exportNumber of results

19 ProductsCompany type

Category

- Steels and metals - machining (4)

- Tools & Hardware (4)

- Milling - machine tools (2)

- Paper - Printing - Machines & Equipment (2)

- Industrial sheet metal work (1)

- Industrial tools (1)

- Machine tools, metal machining - parts and accessories (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Metal industrial presses (1)

- Planing lathes, automatic (1)

- Polishing - steels and metals (1)

- Screw cutting - steels and metals (1)