- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool department

Results for

Tool department - Import export

PHILPLAST LTD.

Bulgaria

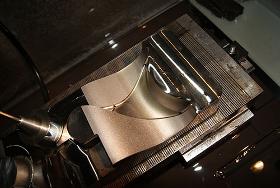

Our tooling engineers and designers have extensive experience in creating various blow molds and injection molds. Our in-house tooling department produces molds for most plastic articles made in Philplast as well as molds for use outside our company. We can design, produce and issue technical documentation before the mold making, or we can make molds from 3D documentation provided by the client. In our tooling production we use new fully equipped high-performance CNC machines. The maximum size of our blow molds is for articles up to 20 liters in volume. The maximum dimensions for our injection molds are 546 x 896mm with a maximum weight of 2,500kg. All molds made to be used in Philplast are thoroughly tested on out machines to ensure their perfect quality.

Request for a quote

PEROZENI SRL

Italy

The machine tool department has a wide range of advanced machinery that enables the company to perform mechanical processes of milling, boring, drilling and lathing on products of medium and large size (single items or small lots). At the present time, the company is able to produce structures measuring up to 12000 x 1300 x 3000 mm height, guaranteeing excellent quality standards every step of the way. The mechanical processes done with CNC machine tools guarantee optimization of the work while reducing production time. The higher quality is observable in the finished piece and in the respect of the tolerances indicated by the client. The company department devoted to mechanical processing on commission is equipped with hoisting systems that facilitate handling. Recently, we installed a bridge crane with a capacity of 32+16 Tons that can be used to move large parts, optimizing the time employed to provide better service.

Request for a quote

AFRIMEX BELGIUM

Belgium

Technical Engine 4.200 cc 6 cyl. diesel 131 HP Manual gearbox 5 gears 4x4 Fuel capacity 90 + 90 L Tropical specifications Interior Fabric seats 3 places Separated air-conditioner Airbags Radio CD Exterior 2 Side doors + 2 back doors Tires 7.5 R 16 Snorkel/tuba Side steps Flash light bar Siren Ambulance equipment Separated ambulance compartment Lightning system rear Closet Aspiration devise Humidifier and oxygen debit meter Mobile stretcher ‘Roll-in’ bed First aid bank Closet department for medical tools First aid kit Ventilation system rear Fire extinguisher

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Tool making We stick to the "single source supply" principle. Marchtrenk is not only the center for the development of products. Here we design and produce the molds for injection molding products exclusively in our own tool making department. Our expertise is concentrated entirely here at our HQ. This makes us independent and we can react in a flexible manner. You do not have to worry whether your tool has been calibrated properly to produce good components – we do that for you. We supply you with perfect silicone or compound parts.

Request for a quote

CARONI S.P.A.

Italy

3D design and production of tools and dies for sheet metal working represents a natural evolution of Caroni Spa’s productive process. The Caroni Study Center first assesses the customer’s requirements, then conducts an in-depth study of technical and commercial feasibility and prepares the plan. When it has been approved, the dies are created. At this point the company’s Tooling Department and Quality Service test the pressed component, which is not mass-produced until it has reached the required quality standard. The customer may of course provide the design. Design All components, dies and machinery are 3D designed with three CAD stations. In the next phase, the mathematics is sent to the processing machinery (CAM) in real time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tool department - Import exportNumber of results

5 ProductsCountries

Company type