- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tin coating

Results for

Tin coating - Import export

MONGIN

France

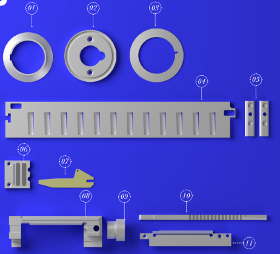

Longitudinal cut N°1 - Holder N°2 - Counter knife N°3 - Slitting knife Transversal cut N°4 - Moving plate N°5 - Fixed knives Design cut N°6 - Magnetic counter knife N°7 - Blade with TIN coating Transversal cutting tool N°8 - Block N°9 - Gear N°10 - Moving blade N°11 - Counter knife

Request for a quote

MONGIN

France

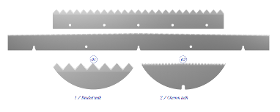

This set of blades acts like scissors. Hardened coating treatment (TIN or CDA) are possible on demand to increase durability.

Request for a quote

MONGIN

France

Shape and teeth of your blade can be adjusted to your raw material and machine requirements. Surface coating, like TIN, and various steel grade are possible.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Introduction: 303 through hardened screw, has better corrosion resistance Tail annealing treatment, greatly improving the toughness of the screw CNC full grinding thread, tooth root top concentric and tooth bottom flatness high precision, can reduce the shear heat. Application: Low acid plastic + GF15 following, such as PMMA, PC and so on Temperature ≤400 ℃ Optical lenses, cosmetic packaging and so on Materials and Process: Material origin: Japan The main components: Cr, V, Mo and so on Heat treatment: vacuum quenching, hardness HRC48-52. (1020-1050 vacuum quenching, high temperature tempering 550-570 more than three times, the rear high temperature annealing softening treatment) Surface treatment: PVD coating (TiN, TiCN, TiAlTiN)

Request for a quote

ROCHOLL GMBH

Germany

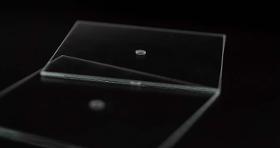

You can also choose from a large portfolio of customizing options for glass as basic material. A wide range of different dimensions and glass grades are available to you. All glass test specimens are offered in various edge qualities. Be it with polished edge, deburred, planed or with non-machined cutting edge: we are guided by your requirements. Would you like to order customized finishing, such as sandblasting, tin coat marks, or drilled holes? We will also be happy to fulfill this request.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Hand wire brushes are used for most manual cleaning processes where corrosion, deburring, debris or detritus is a problem. Alternatively they also create surface abrasion. Our very extensive range of wire brushes are available in all types of wire including: Carbon Steel, Zinc Coated, Brass Coated, Tin Coated, Galvanised, High tensile, Spring Steel, Stainless Steel, Inconel, Nickel Silver, Brass, Phosphor Bronze, Beryllium Copper & Titanium. Handles are available in Beech, Marine Plywood, Polymers, Aluminium & Copper. Handle sizes are dependent on the application and we are able to supply bespoke handles if required.

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

SURFACE FINISH. APPROVED FINISHES EN 10202 Bright, Fine stone, Stone, Silver, Matt COATING. PRECISE VALUES FOR TIN COATINGS EN 10202 HICKNESS TOLERANCES Thickness tolerances and edge reduction according to EN 10202 The thickness of the material must meet the following requirements: a) Deviation from the agreed thickness, measured on the centre line of the strip, must not exceed ± 5%. b) Deviation from the agreed thickness, measured at any point at a distance of no less than 6 mm from the sheared edge, must be between +5% and -8%. WIDTH TOLERANCES Other, closer dimensional tolerances are possible under a commercial agreement. EDGE CAMBER TOLERANCES Tolerances for edge bending under commercial agreement.

Request for a quote

VINCO

Spain

SURFACE FINISH. APPROVED FINISHES EN 10202 Bright, Fine stone, Stone, Silver, Matt COATING. PRECISE VALUES FOR TIN COATINGS EN 10202 HICKNESS TOLERANCES Thickness tolerances and edge reduction according to EN 10202 The thickness of the material must meet the following requirements: a) Deviation from the agreed thickness, measured on the centre line of the strip, must not exceed ± 5%. b) Deviation from the agreed thickness, measured at any point at a distance of no less than 6 mm from the sheared edge, must be between +5% and -8%. WIDTH TOLERANCES Other, closer dimensional tolerances are possible under a commercial agreement. EDGE CAMBER TOLERANCES Tolerances for edge bending under commercial agreement.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Anodizing, galvanizing, passivation, painting: Mifa offers customers all possible surface treatments. A good surface treatment can protect against corrosion, reduces wear or friction, can be electrically insulating or conductive, and in many cases makes the product visually more attractive. Mifa sees surface treatment as the nishing touch that not only increases durability but also adds extra functionality to the aluminium product. The main surface treatments for aluminium that Mifa offers can be roughly divided into three categories: - Conversion layers: aluminium passivation, anodizing, and plasma electrolytic oxidation - Galvanic coatings: chemical nickel-plating, silver, gold, tin, hard chromium etc. - Organic coatings, painting, paint primers, adhesive primers CVD (Chemical Vapour Deposition), PVD (Physical Vapour Deposition), and synergistic coatings can also be applied on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNECOL ADHESIVE IDEAS, S.L.

Spain

Soldering fluxes. Clean and prepare metals, giving a perfectly even coating of the tin to create perfect, fault-free welds. Avalailable in liquid, gel and paste form.

Request for a quote

LEONI DRAHT GMBH

Germany

Shielding braids consist of bobbin wires, located parallel, which have been braided into a tube. Manufactured from Cu-ETP1, Cu-OF1, LEONI-Histral®-alloys (upon request), aluminium and stainless steel, with coating in bare, tin-plated, nickel-plated or silver-plated, hard or soft annealed. Sinlge-wire diameter ranging from Ø 0.10 mm to Ø 0.40 mm. Cross-section ranging from 0.25 mm² bis 400 mm². Tubular shielding braid is smoothly expandable and has a very good shielding effect. The couverage can be determined precisely by changing the braiding angle. Suitable for electrical and mechanical shielding of wires, cables, cable bundles and cable harnesses.

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Material: sheet steel with silicon coating Proficoat 100 Tins: deep-drawn Sets: with adjacented frame Scallop-edged Cake Tins: "Dom-Cake" "Strong" Scallop-edged Cake Tin Set half round Other special individual tin sizes and frame versions can also be produced for larger order quantities, and provided in case the relevant tooling is available.

Request for a quote

STANCMETAL

Serbia

Fastons serve for extending or finishing separate conductors used in electrical or automotive industry. Depending on the use, Stancmetal produces different faston types such as faston tabs, flat plugs, splices, socket contacts, cable lugs, ring tongues, spade terminals, etc. Our company’s fastons conform to German DIN standard, they are made of brass and steel strip with nickel and tin coating. Our fastons enable fast connection between conductor and appropriate device. A quality contact is the one which doesn’t lead to changes while establishing it between fastons after switching on and off for ten times.

Request for a quoteResults for

Tin coating - Import exportNumber of results

22 ProductsCompany type