- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tin and alloys

Results for

Tin and alloys - Import export

COLIMET SRL

Italy

high purity anodes, rods, spheres of Tin

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product Name: Copper Tin Nickel Alloy Width:10-630mm Material:Bronze Grade: Oxygen Free Copper Cu (Min): 75% Model Number:Copper Alloy Place of Origin: China Size: Customised Standard: JIS ASTM DIN EN ISO Certificate: SGS / ROHS / ISO9001:2008 Package: standard export packing Price Term: CIF CFR FOB Ex-Work etc. Usage: Electric Components Lead time:20 Days

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

WELDING FEATURES With a simple fusion, two parts can be combined. Large and heavy parts such as blocks and pipes can be welded using eutectic and tin-lead solder or melting alloys with low fusion points.

Request for a quote

ANKARA BRONZ

Turkey

With a simple fusion, two parts can be combined. Large and heavy parts such as blocks and pipes can be welded using eutectic and tin-lead solder or melting alloys with low fusion points. CORROSION FEATURES Resistant to distilled, salty and fresh water. Affected by strong acids, alkalis and acid salts. Oxygen presence in solution increases response speed.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

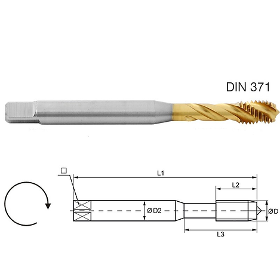

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

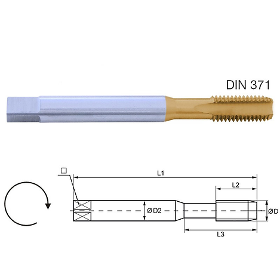

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

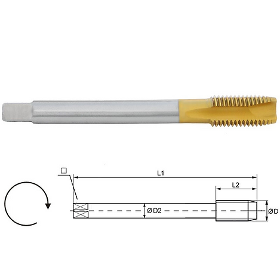

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: General use (long-life version) Material of product: HSSE Surface treatment: TIN For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

COLIMET SRL

Italy

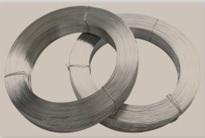

Tin and Tin alloys wires for thermal spray

Request for a quote

AXON CABLE SAS

France

Axon' offers an extended range of equipment wires and cables for any applications requiring resistance to high temperatures. Different types of constructions can be proposed and delivered ex stock. They are designed to resist high temperatures ranging from -90°C to +260°C depending on the insulation material ; PTFE, ETFE, FEP or polyimide. They are made with silver plated or nickel plated conductor copper alloy, tin, silver or nickel plated copper. They can be used for various applications: aeronautics, automotive, space telecommunications, electronics, military equipment, general industry, ...

Request for a quote

SMA ACCUMULATORI GMA POINT SERVICE

Italy

Starter batteries car Asia The batteries in this series are designed and manufactured for all applications foreseen by Asian cars. The use of lead/calcium/tin alloy grids guarantees very low water consumption, high resistance to corrosion and low levels of self-discharge (in compliance with ideal storage conditions). Battery capacity: 35ah; 45ah;: 80ah; 100ah.

Request for a quote

LBI

France

Sand casting of copper alloys: tin bronzes, lead bronzes, brasses, nickel aluminium bronze, copper and special copper alloys. Maximum weight: 2 tons Staff: 70 employees. Turnover: approx. 10 M€ BP 64 - Rue de l’Embarcadère F - 03600 COMMENTRY Tél. : +33 (0) 4 70 64 58 80 Fax : +33 (0) 4 70 64 64 87 Site web : www.sri-foundry.com E-mail : commercial@sri-foundry.com

Request for a quote

CDI VALLÈS S.L.

Spain

Controlled foam detergent for crate washing and CIP systems in agriculture and livestock industry Low foaming liquid cleaner suitable for the treatment of circuits, tanks, pasteurisers, machines, tanks, containers and utensils used in the agricultural and livestock industry. It allows the removal of organic residues such as fats, proteins and adhering blood residues, as well as preventing the formation of salt and milk stone residues. Product especially indicated for the simultaneous cleaning and deodorisation in manual or automatic washing systems of all types of tools and containers (trays, boxes, tools...) in farms, as well as in the agricultural and livestock industry in meat, slaughterhouses, dairies, poultry farms, etc. It is also used in CIP application systems. Do not use for cleaning aluminium, tin, zinc or their alloys (brass, ...).

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Spinodal strip materials in Copper-Nickel-Tin alloys offer high ductility for forming into shaped charge liner material for the perforation of oil and gas well liners. Shaped Charge Liner Material Advantages The Spinodal material is produced through our wrought powder compaction process which imparts properties allowing the material to virtually ‘disappear’ upon activating the charge. The material is well suited to “big hole” applications for perforating charges and leaves little residue (commonly referred to as ‘carrots’ or ‘slugs’). Pfinodal® (C72900) and AM-388™ (UNS C72650) We produce two spinodal alloys for these shaped charge applications - Pfinodal® (C72900) copper alloy and AM-388™ (UNS C72650). They benefit from age hardening techniques that further increase their strength and hardness required for deep hole penetration applications. These spinodal materials deliver superior mechanical and physical properties in comparison

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tin and alloys - Import exportNumber of results

18 ProductsCompany type

Category

- Tools & Hardware (4)

- Tin and tin alloys (3)

- Steel & Metals (2)

- Zinc and zinc alloys (2)

- Accumulators and batteries (1)

- Aluminium and aluminium alloys (1)

- Batteries (1)

- Disinfectants, non-medical (1)

- Electric cables (1)

- Foundries - copper, bronze and brass (1)

- Steels and metals - machining (1)

- Steels, nickel (1)