- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tig welding system

Results for

Tig welding system - Import export

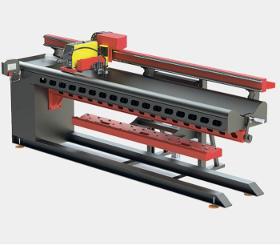

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

RPJM SOLUTIONS

Portugal

We specialise in CNC precision machining of metal alloys, composites and industrial plastics, as well as welding, for the production of parts for a wide range of industrial applications, with project development and assembly if required.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our company specializes in a wide range of welding services, with an emphasis on high quality welding welds. We use modern technologies that guarantee excellent results. We carry out welding of a variety of materials, including carbon/structural steel, stainless steel and aluminum. Our production facility meets stringent quality standards, such as PN-EN ISO 3834-2:2007 and PN-EN 1090-2:2018-09. We have implemented modern welding technology for group 1.1 and 1.2 carbon steels in accordance with PN-EN ISO 15614-1:2017-08. Our skills include working with steels such as S355J2 and steels with lower yield strengths, especially for material thicknesses above 3 mm for fillet welds (3-23 for butt welds), welded using the MAG-135 method. We provide professional execution of any steel welding service.

Request for a quote

PEMAT S.C.

Poland

TIG WELDING WIRE 12.64 1.6MM 1KG Copper-plated welding wire 12.64 with increased content of Si-Mn components. The binder provides higher weld strength and resistance to contamination of welded elements. It also promotes low sensitivity to surface contamination and contributes to smooth, solid welds. Used e.g. in construction, manufacturing and shipbuilding. TECHNICAL DATA: Wire diameter: 1.6mm Weight: 1kg Wire type: 12.64 Bar length: 1000mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIGTEC FISCHEREDER KG

Germany

Tungsten inert gas (TIG) welding offers many advantages over other fusion welding methods, such as the complete absence of spatter and low welding-fume emissions. Since TIG welding uses a non-consumable electrode, the process is ideal for welding so-called root passes or in forced positions due to the decoupling of current and welding consumables.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Intelligent manufacturing Full automation Custom design For TIG, MIG, Plasma or other welding process

Request for a quote

ALSEN SERVICES LDA.

Portugal

STAINLESS STEEL Boiler Welding in position PB 2F, STAINLESS STEEL TIG. Welded in position PB 2F, INOX TIG in professional working conditions with ruequerimento and adjustments.

Request for a quote

MAHERAS LTD.

Bulgaria

We have 10 TIG, MIG and ARC welding machines. Our welders are among the best in Bulgaria. We can weld everyone steel.

Request for a quote

EWM AG

Germany

EWM welding consumables for MIG/MAG welding Welders can choose between different welding rods with different diameters and materials to work with: — unalloyed steels — low-alloy steels — high alloy steels — Nickel-based materials — aluminium alloys — Copper-based materials — Hardfacing

Request for a quote

EWM AG

Germany

TIG inverter welding machine with high frequency start. Thanks to the modular structure, the machine can be retrofitted with an additional water block without using any tool. With the two available control variants (Smart 2.0 or Comfort 2.0), a variety of functions are available: — TIG Liftarc welding without HF — MMA pulsing — TIG pulsing (sec/kHz) up to maximum 15 kHz — TIG AC welding — TIG AC pulsing (sec/special) — Non-latched/latched operation — Adjustable up-slope and down-slope time — Adjustable gas pre- and post-flow time — MMA welding — Adjustable hot start current and hot start time — Adjustable Arcforce — Antistick function Available as DC and AC/DC variant with optional torch connection for standard start/stop welding torch or up/down torch.

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc PCW Precision Circumferential Welder provide all of the features necessary to position and rotate parts for circumferential welding. Advantage: 1. The extreme accuracy welding lathe with servo motor control for turntable and transverse carriage. 2. Allow unskilled people to get high welding quality and consistently production progress. 3. Designed to enable horizontal or vertical configuration for more flexible welding solution. 4. ProArc offers a user-friendly and intuitive controller interface that allows users to implement the system quickly. 5. ProArc designed AVC (option) Enable to set the parameter of AVC in the integrated controller. 6. Motorize carriage on X axis (option) Ball screw drive system with dual linear guide way. * Positioning accuracy is +- 0.01mm * Travel speed 1 ~ 10,000 mm/min 5. Maximum through hole for diameter 80mm. *CE Conformity

Request for a quoteResults for

Tig welding system - Import exportNumber of results

14 ProductsCompany type

Category

- Welding work - steels and metal (3)

- Gases, compressed and liquefied (2)

- Welding, electric - equipment and supplies (2)

- Autogenous welding machines (1)

- Handling - Machines & Equipment (1)

- Laser - cutting and welding machines (1)

- Milling - steels and metals (1)

- Steels and metals - welding and brazing (1)

- Vacuum cleaners - industrial (1)

- Welding, soldering and brazing - equipment and supplies (1)