- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoplastic polymers

Results for

Thermoplastic polymers - Import export

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our recylcing machinery can process multiple types of thermoplastic polymers in diverse forms. Important is that the waste is clean, contains one polymer only and is thermoplastic. Our largest polymer is PVC. About 60% of the processed plastic waste is rigid or soft PVC. The reaming 30% are mainly PP and HDPE but also LDPE and multiple engineering grade polymers. The plastic waste can be mixed or single-colour (black, white, grey etc.). We buy plastic scrap of the following polymers: We can process many different types of plastic waste independent of form or size. Our recycling machinery enables a flexible recycling of solid, thin-walled and powdery plastic waste.

Request for a quote

SC PROFINOX SRL

Romania

We provide professional powder coating services to achieve a smooth and pleasant finish on your products. The powder coating process ensures efficient and long-lasting surface coverage and costs are considerably optimized. The Profinox team recommends the use of powder coating if you want the surface of your product to have a different look from the one obtained through stainless steel sandblasting or mechanical finishing. You can choose powder coating both for a normal stainless steel painting process, and for elements obtained by laser cutting. The powder coating service performed by Profinox provides you with a high-performance and efficient technique. The process is carried out using a fine powder (a thermoplastic or thermosetting polymer) which is sprayed on and adheres electrostatically to the substrate. After the powder has been evenly distributed, the final step is to fix the paint. This is achieved by exposing the polymers to a temperature of about

Request for a quote

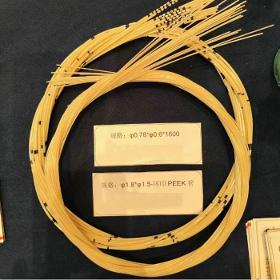

PEEKCHINA CO., LTD.

China

PEEK Performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK film offers an outstanding range of physical, thermal, chemical & radiological properties. PEEK is a high performance semi-crystalline thermoplastic. PEEK's characteristics include high temperature performance, excellent wear properties, superior chemical resistance, hydrolytic stability and outstanding toughness and strength. PEEK meets many aerospace, automotive, fire, smoke and toxicity, food/water, medical/pharmaceutical, and military approvals and standards. FEATURES AND BENEFITS of PEEK Film PEEK (polyetheretherketone) Film Provides: · High Temperature Performance · Excellent Tribological Properties · Broad Chemical Resistance · High-Strength & Toughness · Electrical Stability & Radiation Resistance · Low Smoke & Toxic Gas Emission · High-Purity, extremely low extractables

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process Injection Molding + CNC Machining Features Made by ARKPEEK composite material, good sealing performance, not easily deformed, stable performance, easy installation, and good insulation. Mainly used in high-voltage motors. Discover the unparalleled performance of our PEEK Labyrinth Seals, engineered for optimal sealing efficiency and durability in demanding industrial applications especially in high-voltage motors appication. Made from composite PEEK material, our labyrinth seals offer exceptional resistance to extreme temperatures, chemicals, and wear, ensuring reliable performance and extended service life. Trust in our precision-engineered seals to enhance equipment reliability and minimize downtime, delivering superior sealing solutions for your critical applications.

Request for a quote

PEEKCHINA CO., LTD.

China

100% unfilled PEEK natural PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties.Mechanical and automotive engineering, nuclear and vacuum technology, transport and conveyor technology, textile, packaging and paper processing machinery, electronic and precision engineering, food processing. Key Features Temperature: -40°C up to +260°C. Creep resistant and excellent resistance to high energy radiation. Hydrolysis resistant, even against super-heated steam. Extremely strong and wear resistant plastic. Noise dampening. Highly machinable. MACHINING PEEK

Request for a quote

VESTA CHEMICALS BV

Netherlands

SilQon Memo (3trimethoxysilylpropyl methacrylate), is a colorless clear liquid which has C10H20O5Si as chemical formula, is used as adhesion promoter at (in)organic interfaces or as surface modifier or as crosslinker of polymers. It is used as a coupling agent to improve the physical and electrical properties of glassreinforced and mineralfilled thermosetting resins if exposed to heat and/or moisture. It is typically employed as a blend additive in resin systems that cure via a free radical mechanism (e.g. polyester, acrylic) and in filled or reinforced thermoplastic polymers, including polyolefins and polyurethanes. It is also used to functionalize resins via radical initiated processes – copolymerization or grafting – and to modify surfaces. 3trimethoxysilylpropyl methacrylate is also known as Triethoxyoctylsilane and NOctyltriethoxysilane. Availability Europe Provided SilQon Memo is on stock in our local

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer that offers excellent mechanical, thermal, and chemical properties, making it a suitable material for various applications, including electric vehicle (EV) motors. However, when it comes to the use of PEEK in flat wires for new energy electric vehicle motors, it's important to consider a few aspects.

Request for a quote

PEEKCHINA CO., LTD.

China

What is PEEK Catheter Tubing? Polyether ether-ketone (PEEK) is a thermoplastic polymer that can be extruded into catheter tubing with desirable properties such as high tensile strength, buckling resistance, good pushability and radiopacity. Why would you choose PEEK medical Tubing? Unlike polyimide, PEEK is melt processable and can be extruded into small diameter tubes for vascular catheters and larger diameter, thin wall tubes for non-vascular applications, such as Natural Orifice Transluminal Endoscopic Surgery (NOTES) devices. What medical devices or procedures is PEEK commonly used in? PEEK vascular catheters provide strong and flexible, small diameter tubing. Non-vascular applications such as endoscopic and laparoscopic procedures often demand larger diameter, thinner wall PEEK tubes.

Request for a quote

BIEGLO GMBH

Germany

The Dexnyl PEEK shrink tube provides a protective layer for sensitive or critical components as an alternative to traditional materials. PEEK shrink tubes are particularly effective in environments where extreme heat or cold, high pressure, or chemicals, water, or dielectric interference endangers wires and electrical components. BIEGLO can offer PEEK shrink tubing with a diameter of 0.965mm to 9.957mm. PEEK is a thermoplastic polymer that is commonly used instead of metal or other types of plastics. PEEK has a temperature resistance of up to 240 ° C and a special resistance to chemicals.

Request for a quote

SPIROL

Germany

SPIROL offers robust, vertical installation machines specifically designed to post-mould install Compression Limiters into a variety of plastic assemblies. The machines can install a single Compression Limiter or multiple Compression Limiters simultaneously into various polymers, thermoplastics and thermosets. SPIROL’s Compression Limiter Installation Machines are versatile solutions designed to be retooled to accommodate changing part configurations. All designs incorporate standardized machine components to reduce factory lead time, improve component reliability, and lower component costs. SPIROL also specializes in application-specific fixtures to ensure that all assembly components are held accurately in place through the installation process.

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our machinery enables great flexibility at constantly high throughput to recycle your plastic waste efficiently and recourse-saving with help of different recycling processes Currently we run two modular recycling lines for clean, single-polymer and thermoplastic waste. One shredding-grinding line for up to 6.000 tons yearly and one modular shredding-grinding-agglomeration line for up to 9.000 tons which enables parallel or in-line grinding and agglomeration. With those two lines we can process any plastic waste the optimal, resource-efficient way. Since the foundation in 1997 we have developed a deep process knowledge for many types of plastic waste, to produce non-cloggy, free-flowing and dry regrind and agglomerate. After every polymer change our recycling lines are cleaned meticulously to avoid contamination from a polymer-mix. All metal parts are detected by metal detection and the recyclate runs through a dedusting machine before being filled into big bags.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Powder coating” is a type of coating that is applied as a free-flowing dry powder. Unlike conventional liquid paint, which is delivered using an evaporating solvent, powder coating is usually electrostatically applied and then heat-cured. The powder can be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is harder than traditional paints. Powder painting is mainly used for coating metals such as household appliances, aluminium profiles, drum components, and car and bicycle parts. Newer technologies allow powder coating with other materials, such as MDF (Medium Density Fiber), using a variety of methods. Powder coating is very often used to properly prepare and protect various metal materials. Choosing this technique is very cost-effective as it has many advantages. Any defects and inaccuracies that remain after processing are hidden under the applied layer of varnish. Moreover, such coatings will be resistant

Request for a quote

SOUNDSORBA LIMITED

United Kingdom

Barriersorba sound reduction sheet is made of high density synthetic thermoplastic polymer mat loaded with naturally occurring minerals. The product is free of lead, unrefined oils and bitumen. It s black/dark grey in colour and the product is recyclable which makes it very eco friendly. Designed to improve the sound reduction performance of walls, floors, ceilings, enclosure constructions, either as a single sound barrier such as a noise curtain, or part of a composite combined with mass and/or sound absorbing materials. Acoustic Performance Installation Barriersorba sheet used to reduce noise transmission across ceiling and floor voids. Barriersorba sheets are flexible and can be hung as noise barrier sheets between ceiling soffits and suspended ceilings to reduce sound transmission between adjacent areas to elevate room to room sound problems via a common ceiling voids. As Barriersorba sheet is quick and simple to install, it can be used in new build as well as refurbishment....

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PE ARTHA-S

Ukraine

Features of polyethene bags Low-pressure polyethene is a thermoplastic polymer produced by the polymerisation of ethylene. This material is distinguished by its particular type characteristics: Frost-resistant (can withstand down to -70 °C). Low absorptive capacity. Vapour permeability. Dielectric. Neutrality to aggressive substances. High-temperature resistance (up to +70 °C). Ease of processing. Advantages of polyethene, polyethylene bags Damage resistance: Polyethylene sheet is resistant to tears, punctures and stretching. It is extremely difficult to deform, which is very important during transport. Printability extends product durability: If required, the polythene bags can be finished with a company logo or logo and brief contact details. The products are completely oxygen-free, which helps to extend the shelf life of the product. High level of transparency: Absolute transparency allows the customer to get a proper look at the contents without having to open the packaging.

Request for a quote

HENGHE MATERIALS& SCIENCE TECHNOLOGY CO., LTD.

United Kingdom

Mainly used as a monomer unit for synthetic rubber, thermoplastic elastomer and other polymers or as raw materials for medicine, pesticide, spices etc. REACH registration certificate available.

Request for a quote

BIOPOWDER.COM (SCHILLING LTD.)

Malta

Fine micronized powder/granules as a bio-filler material for the following applications: 1. Cosmetics: cosmetic filler and abrasive - microbead replacement 2. Polymer Applications (thermoplasts, duroplasts, resins) 3. Paints, Adhesives, Resins: reactive filler Our product can be supplied in a variety of micron size ranges - from fine powders in the nano and micrometer range up to coarse granules of several millimeters. Product variants are: 1. Natural grade: untreated, consisting of 100% olive stones in food quality 2. Irradiated grade: sterilized grade 3. Silane-treated grade: hydrophobic variant 4. Colored grade: permanently colored bio-flakes We ship small and large volumes worldwide.

Request for a quote

3DMITECH LTD

United Kingdom

TPU 92A (Polyurethane) Flexible and resilient thermoplastic is excellent in the areas of elasticity and strength. TPU 92A thermoplastic polyurethane used to form flexible elastic materials. These can be rolled into plastic substrates for glasses and phones or laptop cases. TPU 92A is a thermoplastic polymer, with Shore-A values of 90. It is highly elongated, high toughness, strong durable and strong. FDM TPU 92A combines elastomer advantages with FDM 3D Print enabling quick production for large and complex elastomer parts. Generally applied are flexible hose and tube ducting and air sealing, covers and vibration dampeners.

Request for a quote

3DMITECH LTD

United Kingdom

ABS is used in the Fused Deposition Modelling (FDM) type of 3D printing. The thermoplastic material is heated, and layers of the material are layered over one another. A solid material used in the moulding industry is ABS plastic. It is a thermoplastic polymer that can make good quality products without having to spend so much money on them 80% of it is used in the printed ABS material products. It is most commonly used in the FDM printing process. Its usage's main reasons are its excellent temperature tolerance and its composition, which makes it liable to all such conditions.

Request for a quoteResults for

Thermoplastic polymers - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Natural polymers (3)

- Plastics - industrial raw materials (2)

- Printing - supplies (2)

- Additives for plastics industry (1)

- Carbon by-products (1)

- Chemistry - laboratory products (1)

- Cutting - steels and metals (1)

- Electric motors and parts (1)

- Films for packaging (1)

- Hoses, pipes and tubes - plastic (1)

- Laser - cutting and welding machines (1)

- Plain bearings (1)

- Plastic products for engineering (1)

- Plastic products for the medical industry (1)

- Polyethylene (1)

- Screw cutting - steels and metals (1)

- Screws (1)

- Seals (1)