- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal imaging systems

Results for

Thermal imaging systems - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

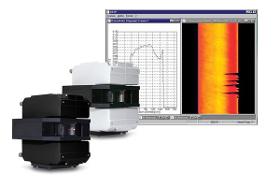

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

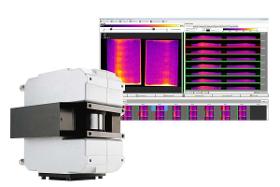

Thermal imaging system based on the Raytek MP150 infrared linescanner. Detailed web temperature profile based on 40,000 measurement points per second Automated temperature monitoring Automated quality monitoring for ISO9000 Ensures proper web temperatures for strong film-to-substrate adhesion Enables plant operators to reduce scrap and improve profitability and product quality Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges Define product-specific configurations (recipes) Automatically analyze “automatic sector” temperature distributions Visualisation on PC Playback stored files as “movie” Multiple language support Integrated OPC server for remote system control Ethernet TCP/IP interface integrated in the line scanning system PC-independent alarm output Analog outputs 3 x 4 – 20mA Analog or digital output modules For sheet extrusion see the Raytek ES150 system.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical offer a range of Stock Sapphire Windows, for use within Infrared Systems. Knight Optical can offer Sapphire (Al2O3) Optics for Infra-red systems over the waveband of 0.2 to 5µm. We offer Sapphire optics for UV, Visible, NIR (0.9 to 1.5µm) and Mid-Waveband Infra-Red (MWIR, 3 to 5µm) Imaging Systems. Sapphire has hardness of about HK2000, which makes it a better choice for windows and outer elements of lens systems. Sapphire has good transmission in the MWIR band, and can be used with optical glass in the NIR, and with Silicon or Germanium in the MWIR, to form well corrected doublets and lens systems. These systems include, for example, Forward Looking Infra-Red (FLIR) systems, and thermography. Al2 O3 has a refractive index of about 1.9288no 1.9174ne at 200nm through to 1.623no 1.615ne in the IR (5µm). This pairing will allow for the design and manufacture of a colour corrected lens that can be used in broad spectrum thermal imaging systems.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer Barium Fluoride Optics for use within Medical Imaging. We supply a range of Barium Fluoride Optics for a range of applications. All individually QA checked and metrology tested for quality to ensure parts meet customer specification. Supplied in a range of sizes and shapes with custom coatings tailored to meet your individual applications. We supply precision optics to customers in the medical industry for applications such as medical thermology and thermography. Barium fluoride optics are used in the detection and screening of breast cancer and for screening for atypical pneumonia (SARS) and monitoring respiratory conditions. Due to barium fluoride’s high radiation resistance, it is ideal for use in high radiation (x-ray/gamma rays) environments. Other applications include cryogenically cooled thermal imaging systems, infrared spectroscopy and high energy neutron detection. For more information read PDF…

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer Calcium Fluoride Lenses for use within the Oil and Gas Industry. We supply a range of calcium fluoride lenses for a range of applications. All individually QA checked and metrology tested for quality to ensure parts meet customer specification. Supplied in a range of sizes and shapes with custom coatings tailored to meet your individual applications. Knight Optical supply precision optical components to customers in the oil and gas industry for use within detectors and spectrophotometers. For spectroscopy, calcium fluoride is superior to many other materials such as N-BK7 or fused quartz due to a lack of OH absorption peaks. Due to calcium fluoride’s low absorption and reflection and high damage threshold these lenses can often be used uncoated and are ideal for use in laser applications as well as thermal imaging systems, spectroscopy and high energy neutron detection. For more Information read the PDF….

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer Barium Fluoride Windows for use within Medical Imaging. We supply a range of barium fluoride windows for a range of applications. All individually QA checked and metrology tested for quality to ensure parts meet customer specification. Supplied in a range of sizes and shapes with custom coatings tailored to meet your individual applications. Knight Optical supply precision optical components to customers in the medical industry for applications such as medical thermology and thermography. Barium fluoride optics are used in the detection and screening of breast cancer and for screening for atypical pneumonia (SARS) and monitoring respiratory conditions. Due to barium fluoride’s high radiation resistance, it is ideal for use in high radiation (x-ray/gamma rays) environments. Other applications include cryogenically cooled thermal imaging systems, infrared spectroscopy and high energy neutron detection. Read PDF for more information…

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The TF Thermoforming Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for thermoforming processes. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. The TF Thermal Imaging System is ideal for applications reaching temperatures from 20 to 350°C (68 to 662°F). MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ES Thermal Imaging System for Sheet Extrusion from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. The ES Thermal Imaging System is ideal for continuous web applications such as hot strip mills, continuous casting, glass wool production, laminating for both glass and plastics and more. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Extrusion Coating EC Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes.The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The GS Thermal Imaging System for Glass Processes from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and low emissivity glass products. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized glass applications – such as glass bending, forming, annealing and tempering – and industrial environments. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ThermoView TV40 is a high-performance industrial fixed thermal imaging system that allows you to expand your understanding by providing continuous infrared and visual feeds to visualize temperature data. The TV40 offers a fully integrated temperature control, monitoring, and data archiving solution. With the ability to personalize your integration, the TV40 allows you to automate your process by programing unlimited "areas of interest," programable alarms, utilize advanced pass/fail logic, and perform safety or asset inspections. Feed the data to your PLC or view feeds remotely. Hardware The rugged TV40 thermal camera lets you visualize the temperature data you need anywhere in your process with reliable, high-quality 320x240 and 640x480 infrared resolution options. Several key features: IP67 (NEMA 4) housing that guarantees long-term thermal imaging in the harshest environments (air purge and other accessories available) Simultaneous infrared and visible sighting

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ScanIR®3 thermal scanner is designed for a wide variety of noncontact temperature measurement applications, including those in harsh industrial environments. Its robust housing incorporates standard water-cooling and air purge and features built-in laser sighting. A rugged processor box provides universal input and output (I/O) capabilities in the field without the need for an external computer. The ScanIR3 linescanner and thermal imaging system has one of the fastest scan speeds in the industry and offers complete data about even the highest-speed manufacturing processes. Unlike point sensors that measure a single point, the linescanner measures multiple temperature points across a scan line. Its motorized mirror scans at rates up to 150 lines per second, allowing rapid detection of temperature non-uniformities and hot spots. Rotating optics collect infrared radiation at 1024 points within a 90-degree field of view, and industry-leading optical resolution

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The TIP900 system is a comprehensive thermal imaging and noncontact profiling system designed to supervise the temperature of wallboards coming out of the oven. It uses an infrared thermal imager to continuously scan the entire board surface temperatures and allows the detection in real time of moisture and density variations inside each board. The powerful TIP900 software provides sophisticated data integration, visualization and event analysis, and offers users a complete solution of real-time monitoring, detection and traceability. It also analyzes and provides optimal oven dryer profile balance. The detailed wallboard quality maps, the historical temperature trend charts and the images can be seen locally at the operator workstation or remotely. All data is stored in the LogViewer database for complete process visibility and long term traceability. TIP900 System Software Detailed continuous board quality monitoring (100% of all board images are archived)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MP150 infrared linescanner is designed for temperature monitoring in demanding industrial environments. It generates accurate thermal images of moving objects, scanning up to 90° wide fields of view with a motorized mirror at up to 1024 points per line and at a max. 150 Hz frequency. An internal high-speed microprocessor calculates the temperature of the individual measurement points. — Real-time thermal line-scanner system for continuous or discrete process measurements — Optical resolution up to 200:1 — Built-in line laser for rapid alignment — On-board Ethernet TCP/IP communication — Wide choice of models and spectral responses The Raytek MP150 includes provision for air or water-cooling, three configurable analog outputs, and two-way digital communications. It can be used in standalone mode, connected to a single PC or integrated into a process control system using the Windows-based DataTemp DP software for remote configuration and real-time process monitoring.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

ThermoView TV40 is a high-performance industrial thermal imaging system for fixed installation designed for factory automation applications. It integrates a visible-light camera and software for temperature control, monitoring, and data archiving. • Wide temperature range: -10 to 1200 °C (14 to 2192 °F) • Rugged aluminum housing, IP67 (NEMA 4) • Ambient temperatures to 200 °C (392 °F) with high-temperature enclosure • Air purge and accessories available • IR-Fusion technology: simultaneous thermal and visible sighting • Remote motorized focus • 320 x 240 and 640 x 480 focal plane array • 9 or 60 Hz models available • GigE Vision interface • LAN/Ethernet with PoE for communication with the camera provides access to Ethernet, Web server and ThermoView Software • Multiple field interchangeable lens options • 2-year warranty

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Thermal imaging systems - Import exportNumber of results

18 ProductsCountries

Company type