- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal control

Results for

Thermal control - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq TP6 is the perfect solution for the most demanding high temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Its robust software options also allow you to read information from the data logger in real-time with the optional Radio Frequency (RF) system and USB/Bluetooth connection options. • Available in 10 and 20 channel configurations and two case styles • Water resistant (IP67 rated) • ATEX certified version available, allowing for safe operation in Zone II classified areas • Communication via USB or Bluetooth • Real time telemetry via USB, RF telemetry and Bluetooth* • Alkaline, NiMH and Lithium battery options • Compatible with the Datapaq Insight™ for mobile application

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

High-temperature greases with high thermal stability and optimum wear protection. They are extremely media-resistant and mainly suited in bearings and conveyor rollers operating at high temperatures.

Request for a quote

DOVENCI CELIK KONS.SERA DEMIR TARIM URUN. INS.TAAH. MET TIC.SAN.LTD.STI.

Turkey

Thermal Heat Curtain

Request for a quote

SCHMITZ FOAM SUPPLY

Netherlands

SOLUTION FOR THERMAL AND ACOUSTIC COMFORT IN HVAC SYSTEMS Our high-performance XPE foam, tackles both thermal and acoustic challenges in HVAC installations, ensuring energy efficiency and a quieter environment. KEY FEATURES - Dual Insulation Power Thermal Control: RoFoam's closed-cell structure minimizes heat transfer, reducing energy consumption and maintaining desired temperatures in air ducts and pipes. - Noise Reduction: The same structure effectively traps sound waves, lowering noise transmission throughout the HVAC system. - Lightweight and Flexible Easy Installation: RoFoam's low weight simplifies integration into existing HVAC systems, while its flexibility allows for seamless installation around corners and uneven surfaces. The lightweight nature of RoFoam minimizes additional load on ducts and pipes. Multiple Applications - HVAC Ducts & Pipes - Industrial Applications RoFoam is available in a range of thicknesses to meet your specific requirements.

Request for a quote

SCHMITZ FOAM SUPPLY

Netherlands

VERSATILE SOLUTION FOR DIVERSE INDUSTRIES Our premium XPE foam offers great versatility for a vast range of applications across various industries. Wide range for diverse needs - We continuously develop new RoFoams and modify existing ones to meet specific industry requirements. - RoFoam offers an excellent alternative or complement to EVA and HDPE types, providing unique benefits in specific applications. - Choose from a spectrum of soft, comfortable grades for cushioning to rigid, high-density grades for structural support. Fit for multiple applications - We offer flame-retardant RoFoams to meet stringent safety regulations in specific industries. - RoFoam's closed-cell structure excels at sound absorption, making it ideal for acoustic insulation applications. - The same structure offers thermal insulation, beneficial for temperature control in various settings. - RoFoam's compression and conformability create reliable gaskets and seals across diverse industries.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Structured optics are produced using turning, milling and planing Technology.. Under thermally controlled conditions we can realize structure depths in the submicrometer range with accuracies also in the submicrometer range. Different types: Microlenses, Grids, Fresnel- optics.

Request for a quote

CRYOSNOW GMBH

Germany

• Extreme low consumption • For difficult to access and delicate parts • For manual blasting operations • Adaptable for use with every type of robot • No build up of ice, as thermally insulated • With CO2 quantity controller

Request for a quote

CRYOSNOW GMBH

Germany

• Extreme low consumption • For difficult to access and delicate parts • For automated blasting operations • Adaptable for use with every type of robot • No build up of ice, as thermally insulated • With CO2 quantity controller

Request for a quote

MAHLO GMBH & CO. KG

Germany

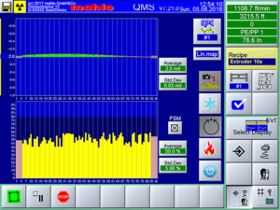

Automatic control of thermal diebolts of extrusion dies The DieControl APC Pro automatically controls thermal bolts of extrusion dies according to the earlier measured cross-section profile of the material. This results in uniformly thick films, sheets or coatings even with fluctuations in the feed, material change or when starting the system. The automatic control and the extrusion close to the set point also achieve considerable material savings and quality improvement.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The polyester high-performance fleece Cora®Deep has a fibre matrix of fine and very fine fibres. Compared to conventional fleeces, it also has a larger layer thickness. Due to the very large amount of "free pores" Cora®Deep achieved above-average dirt-holding capacity (depth filtration). The controlled thermal stabilisation of the high-performance nonwoven allows a classified separation of the particles (large, medium, fine). The Cora®Deep nonwovens are subjected to a novel surface treatment process in order to meet the increasing requirements for a minimum fibre release of filter fabrics: Glazing - a combination of flames and calendering. This means that even the finest particles (5μ, 2μ) are retained.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Heating bands are the ideal solution for the heating of tubes an cylinders. Mica band heaters, frequently used as nozzle heaters, are made with a plastic-tight stainless steel casing. Such mica heating bands are in many dimension available from stock. The Ceramic heating band type is suitable specially for applications with high watt density and therefore for higher temperatures. Ceramic band heaters, also known as ceramic ring heaters or cylindrical ceramic sectional heaters, are attached to the contact surface by means of a clamping mechanism. A preferred field of use for ceramic band heaters is the heating of plasticising cylinders, bushings and nozzles of injection moulding machines and screw barrels of extrusion machines. For thermal optimization and process control ceramic band heaters can also be offered with insulation jackets or air cooling.

Request for a quote

CRYOSNOW GMBH

Germany

• For large surface cleaning • For stubborn contaminations • Very efficient production of CO2 snow particles • Gentle apportioning in compressed air • For manual blasting operations • Adaptable for use with every type of robot • No build up of ice, as thermally insulated • With CO2 quantity controller

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Ceramic Cavity Laser Reflectors Introductions : High purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity. Ceramic Reflector Prime Features: > Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk refectivity > 97% reflectance efficiency at 600-1000nm > Reflectance efficiency exceeds 95% across the wavelength range 400-1200nm (see curve) > Controlled porosity > Good thermal conductivity > High electrical resistivity Ceramic Cavity Laser Reflectors Physical properties: > Color: White > Bulk density (fired), Mg/m3 :3.1 > Porosity (apparent), % nominal :22 > Flexural strength (ASTM C1161, 3-point), MPa :170 > Thermal expansion coefficient 200-500C, 10-6 /C 7.9 200-1000C, 10-6 /C 9.0

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The material of ceramic reflector is 99% Al2O3.Its green body is fired at a suitable temperature to retain the proper porosity and strength. The surface of the ceramic reflector is coated with a high reflectivity ceramic glaze ,so compared with the gold-plated reflector , its has long service life and diffuse reflection. Prime Features: - Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk refectivity - 98% reflectance efficiency at 600-1000nm - Reflectance efficiency exceeds 96% across the wavelength range 400-1200nm (see curve) - Controlled porosity, Good thermal conductivity, High electrical resistivity. Physical Characteristics: - Color: White - Density: 3.1Mg/m^3 - Porosity: 22% - Flexural strength: 170Mpa - Coefficient of thermal expansion: 7.9×10^-6--/С (200~500℃) 9×10^-6/С (200~1000℃)

Request for a quote

VENALSOL SMART LIGHT S.L.

Spain

PLI7 series projector, with a modular design for thermal performance superior and controlled. Large PCB with dissipation envelope throughout the contact surface. Optical group separated and isolated from the module's drivers, with stainless steel screws and quality waterproof connections. The implementation of 1301m / W SMD LED t echnology with the use of Specialized lenses is suitable for long distances. NF2L757DR Japanese technology of high power and durable. The selection of the ideal product is essential to obtain the best financial result, and excellent lighting comfort in the medium and long term.

Request for a quote

GAICTECH

Spain

The Tuna Fish Steam Cooker is expertly designed to refine the production process for tuna, focusing on increasing total fish yield through precise thermal gradient control and moisture content preservation. This ensures the fish remains moist, facilitating easier cleaning post-cooking. Tailored for flexibility, it offers adaptations for client-specific trolleys and the option for cooking without vacuum, enhancing its utility in diverse processing environments. Remote support capabilities allow for diagnostics and adjustments via PC and Ethernet, ensuring seamless operation and troubleshooting. Constructed from high-quality stainless steel AISI 304 L, the cooker is built for durability and hygiene compliance. Key features include a fully automatic cooking cycle, options for time or temperature-driven cooking directly in the fish's bone, and advanced process control via the latest generation PLC with exclusive tuna cooking programming. Temperature monitoring through thermocouple

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® Ni 52 is a Nickel-Iron alloy with a thermal expansion characteristic that corresponds to soft glass. Applications include magnetic reed switches and seals that need controlled linear expansion to about 1000°F. The alloy is readily formed or deep drawn from a fine grain annealed temper. Joining can be accomplished by conventional welding or brazing techniques. Useful magnetic characteristics can be produced from a continuous strand anneal. Available Sizes: HPM® Ni 52 available from Hamilton Precision Metals as strip product in thickness from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to UNS N14052.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROPEM

Belgium

Flare Systems Since the 1980’s, key staff of Europem have been responsible for the design, fabrication, installation, commissioning and maintenance of numerous flare systems including some of the most stringent and demanding applications. Europem’s extensive experience in flare design has resulted in a comprehensive range of elevated and ground flare systems and ancillaries to cover the needs of all major industries. Low and High Pressure Utility (Pipe) Flares Air assisted Flares Steam assisted Flares Gas assisted Flares Sonic Flares Speciality flares for Ammonia, H2S, LNG and lean waste gas Mobile Flare systems – for purchase, lease or rental Venturi Flame Shields protecting the flare from flame lick and improving combustion efficiency Ancillaries such as pilots, ignition systems, pilot detection, KO drums, water seals, molecular seals and conical purge seals Supporting structures including derricks, demountable riser type derricks, guy wire support systems, plus self supporting Flares Enclosed ground flares with single or multiple burners Temperature controlled combustors and thermal oxidisers. Europem aims to be a long term partner to all our clients and provides full aftermarket support for all operation, maintenance and intervention requirements. We can also provide for the inspection, maintenance, refurbishment and replacement of any flare system or components and can supply in some cases, rental flares during maintenance interventions.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability. That’s why leading defense programs use our high-performance materials. Leadership in Defense Metals We have more than 50 years of experience developing precision strip and thermal management products for critical defense applications worldwide. Our defense portfolio includes: Thermal management materials for semiconductor heatsinks Nickel strip for battery connectors High Performance Defense Alloys Molybdenum Copper (AMC) and Tungsten Copper (AWC) High purity nickel strip Trusted for Critical Defense Applications Due to their excellent thermal conductivity and controlled thermal expansion, our Molybdenum-Copper and Tungsten-Copper composites are the preferred materials for Gallium Arsenide (GaAs) and Gallium Nitride (GaN) semiconductors for the defense industry. Our heat spreader materials are trusted in sensitive applications such

Request for a quote

EUROPEM

Belgium

Utility Flares (Pipe Flares) are the most basic flare design available, to provide a robust, reliable and flexible solution for the flaring of large volumes of low pressure waste gas when smokeless operation is either not required or can be achieved without an assisting medium (like steam, air or gas). Reliable operation at both full load and partial load is possible. Key features Flame holders fitted on the periphery of the flare tip ensure stable operation. These flame holders provide a zone of recirculated flue gases, which prevent flame lift off, from the flare tip. Wind deflectors to prevent flame impingement, which prevent a low pressure zone, downwind of the tip. Pilot burner arrangement to further stabilise the flame. Use of high grade alloys to enhance lifetime of the flare tip Use of dynamic seal to reduce purge gas requirements and prevent flash back. Key advantages Low investment and operational costs Low maintenance costs with the use of high grade alloys and the robust design. Reliable and stable flaring in a wide range of operating conditions Large turn-down ratio Applications Upstream oil & gas sector LNG terminals and NG compression stations Chemical and petrochemical industries including refineries Food processing industries Municipal solid waste treatment (biogas and landfill gas) plants Temperature controlled combustors and thermal oxidisers.

Request for a quote

STAMIXCO AG

Switzerland

The SMN Injection Molding Static Mixing Nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous polymer melt flow is homogeneous with regard to colorant, additives and temperature. Benefits Outstanding melt flow mixing of molten polymer prior to injection results in the following benefits: Reduced spots, streaks and clouds of color Reduced colorant usage (10% - 40) Narrower part tolerance Reduced reject rates Less part distortion Less weight variation Improved part quality when using regrind material Shorter cycle time Improved melt flow Increase regrind ratio with consistent product quality Rapid nozzle heat-up Normal Pay-back period of 2-3 months Filter for Injection Molding Static Mixing Nozzle (Type SMF) The optional SMF Filter is installed inside of the Static Mixing Nozzle to protect the hot runner system and mold when processing regrind materials by avoiding clogging and/or damage with debris carried along with the feed pellets. Grid Protection Disk for Mixing Elements (Type GPD) The optional GPD Grid Protection Disk is installed inside of the Static Mixing Nozzle upstream the first mixing element. During the start-up operation it avoids a possible so called “cold-start” damage of the mixing element grid by plugs of not completely molten and thus partly solid polymer plugs originating from the transition part between the end of the barrel and the Static Mixing Nozzle Benefits & Function The SMF Filter is designed to be used with the SMN Injection Molding Mixing Nozzle. The purpose and functionality of the SMF filter are numerous: Protects hot runner system and mold by avoiding clogging and/or damage caused my metal pieces accidentally introduced with the feed pellets to the injection molding machine (staples, metal chips, paper clips, etc). Retains semi-molten polymer pellets until melted for incorporation into the polymer melt For customers with poor thermal control systems, the SMF Filter acts as an upstream breaker-plate to prevent “cold-start” crushing of the mixing elements. Designed to retrofit into the SMN Injection Molding Mixing Nozzle without nozzle modification O.D. of SMF Filter = O.D. of SMN Mixing Elements Length of one (1) SMF Filter = Length of two (2) SMN Mixing Elements O.D of GPD = O.D. of SNM Mixing Elements Length of one (1) GPD = Length of one (1) SNM Mixing Element

Request for a quote

EGE KESKIN CAM ISICAM

Turkey

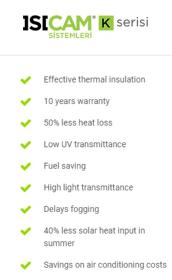

Isicam Systems is a K Series product. It is produced with Şişecam Solar Low-E Glasses with high quality heat and solar control coating. By providing effective thermal insulation and solar control, it reduces fuel costs in winter and air conditioning costs in summer Advantages : Compared to ordinary double glazing, it reduces heat losses by 50%, reducing fuel costs in winter, and reducing the penetration of solar heat by 40%, reducing air conditioning costs in summer and providing energy savings. While providing heat and sun control, it does not compromise transparency and natural daylight. With its low reflectivity, it increases the comfort of viewing the landscape in projects where the view is important. It prevents window fronts from being cold in winter and hot in summer, and delays fogging compared to ordinary double glazing. Compared to ordinary double glazing, the expenditure made for Isicam K returns in 1-2 years with the savings to be made in fuel and air conditioning costs.

Request for a quote

ARMACELL GMBH

Germany

QUICK AND EASY TO APPLY FIRESTOP FILLER FOR PIPE PENETRATIONS WITH ARMAFLEX PROTECT Armaprotect 1000 Firestop Filler is a particularly practical, ready-to-use, high-temperature resistant mortar with excellent fire-protection, thermal insulation and noise control properties. It is self-hardening and very easy to apply by hand. No need for formwork – and it can be used even in tight spots. The protective halogen-free insulation to reduce corrosive effects and smoke toxicity in case of fire

SNK GMBH

Germany

・Rigid structure with a flat, wide beds built for heavy cutting ・High-precision headstock with thermal balance function ・Adjustable control panel for operator convenience ・Ideal for a wide variety of turning processes ・Large diameter built-in center standard on tailstock. ・Ideal for long work processing with various follower rest attachments ・Maximum Swing Diameter: 1,600mm – 2,500mm (standard); up to 4,000mm ・Center Distance: 6,000mm (standard); customizable ・Workpiece Capacity: 70,000kg (standard); up to 400 Tons

Request for a quote

FRIGO ŽIKA DOO

Serbia

Refrigerating chambers have wide range of application in all activities and they are used for keep in fresh the products for the storage and fast freezing. Because they are made by Buyer special dimensions which means that they could be placed in the different place. They are made of the best quality thermal-insulation panels. Thicknesses of insulation panels: 60 , 80 , 100, 120 , 140 , 160 mm Correspond completely to the work temperature from - 40 to + 70 oC Cooling mode: depends on client wish. Sanitary molding installation. Automatic work control. Lighting. Standard thermal-insulation door dimension is 800 x 1900 mm. Besides of that dimension we can produce door of special dimensions by demand of the buyer. For more information and other products feel free to contact us.

Request for a quote

MAVIFLEX

France

Characteristics of partitions and welding curtain Mavitoile Ideal for dividing off areas in factories Thermal insulation, noise, dust, thermal barrier Spray and fume control So easy to install-on fixed frame or sliding track No space limitation – Made to exact custom specifications Option : Vertical vision pane Double skin curtain to increase the insulation Made to mesure Manual door >> Modular partition in flexible curtain

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide designs and builds customised energy centres which generate heat which can then be distributed to buildings or district heat networks. We can also incorporate CHP units within the energy centre, providing electricity along with heat and a low carbon heat and power solution. Our energy centres are often designed to have more than one energy source, allowing the plant operator to vary the energy sources in relation to the energy demand and the best value for money at a given time. The energy sources may include: Gas fired boilers. Biomass boilers. Heat pump. Oil fired boilers. Combined Heat and Power (CHP) unit Our centres are engineered to include the energy sources, thermal stores, instrumentation, control systems, pumping and pipework network – building in as much flexibility as possible so that the plant can be operated as efficiently as possible.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

District heating systems include a centralised energy centre which then distributes the heat through a network of insulated pipes to the buildings which are connected to the network. The network of pipework consists of a flow and return loop which passes each building. Colloide uses local substations in each building to control the flow of water from the district heating pipework loop through each substation and this flow is used to generate heat in the local building. The central energy centres are generally designed to have more than one energy source, which allows the plant operator to select the most cost efficient and sustainable way of providing the energy needed with the energy sources being brought on and off line to meet demand. We design and build the district heating and cooling networks to include the pumps, pipework, thermal stores, instrumentation, control systems, local substations, heat exchangers and communication through a central control system.

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

For thermal insulation Temperature controlled up to 55 °C Optionally ULTRA.sens® or INFRA.sens® With dust filter Temperature range 5°C - 45°C

Request for a quoteResults for

Thermal control - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Blast cleaning equipment (2)

- Energy - renewable (2)

- Foams, rubber and plastic (2)

- Ceramics, industrial (1)

- Ceramics, refractory (1)

- Cold rolled steel strips (1)

- Cold rooms (1)

- ELECTRIC EQUIPMENT (1)

- Electroheat - machines and equipment (1)

- Filtering equipment and supplies (1)

- Glass, reinforced (1)

- Glass, tempered (1)

- Greases, industrial (1)

- Halogen lamps and spotlights (1)

- Heat treatment furnaces (1)

- Milling - machine tools (1)

- Moulds, plastic and rubber industry (1)

- Plate glass and mirrors (1)

- Spotlights (1)

- Steam polishers (1)